Research on organic nonlinear materials dates back a couple of decades, but those efforts have only recently started paying practical dividends. Lumera (Bothell, WA) has introduced a family of high-speed electro-optic modulators based on nonlinear organic materials that reach data rates of 100 Gbit/s. Organic compounds with strong two-photon absorption have been used to demonstrate a new type of three-dimensional microfabrication with extremely high resolution. Both DARPA (www.arpa.mil) and the National Science Foundation (www.nsf.gov) are sponsoring ambitious development programs.

The promises and perils of organics

If your first reaction to any proposals for plastic components is wariness, you’re not alone. Plastic optics have suffered performance problems, including poor durability, discoloration, high absorption, and internal inhomogeneities. Those problems haven’t gone away. Last year a pair of spectacle lenses degraded before my eyes as the high-index plastic yellowed and shed their coating, and the optician admitted they were only supposed to last a couple of years.

The emerging generation of organic nonlinear materials represents a different approach, designed to offer premium performance. Organic compounds have a nearly infinite range of structural variations, and chemists have learned how to produce new molecules with strongly nonlinear optical properties. The light-sensitive molecules are called chromophores; typically they are large and complex, and designed by theoreticians to provide desired nonlinear properties. The nonlinear effects arise from manipulating the properties of conjugated electrons shared among several atoms in the large chromophore molecules, says Kenneth Singer, now at Case Western Reserve University (Cleveland, OH). Chromophores can form glassy materials by themselves, be added as side chains to other polymer-forming compounds, or dissolved in polymers. “It’s a real playground for chemists,” says Singer. We’ll leave those details to the chemists and concentrate on the optics.

The first-order goal is to produce high nonlinearity of the desired type, but developers face tradeoffs. Nonlinear optical materials must be able to tolerate high light intensities, and withstand normal operating temperatures. Optical-scattering losses typically are higher in organics than in inorganic crystals, but high nonlinearity can offset this factor by allowing the use of smaller devices.

Electro-optic modulators

The electro-optic effect is a second-order nonlinearity that makes the refractive index of a material vary strongly with an applied electric field. It is widely used in external modulators where different voltages are applied across the two arms of a Mach-Zehnder interferometer, causing a relative phase delay that modulates the output intensity.

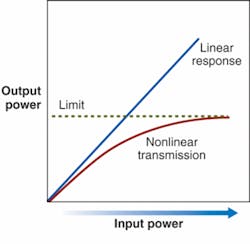

Lithium niobate is the best inorganic crystal for high-speed modulation, and is capable of operation at 40 Gbit/s, but relatively high drive voltages are needed to change the refractive index enough to cause the required phase shift. The efficiency of the best periodically poled organic electro-optic materials-measured in picometers of phase shift per volt as the r33 coefficient-first exceeded the 30 pm/V of LiNbO3 a decade ago, and is now a factor of 15 higher (see Fig. 1).

The higher nonlinearity reduces drive voltage requirements for polymers to a couple of volts for Lumera’s 40 Gbit/s modulators. But Lumera also offers a model at 100 Gbit/s, beyond the reach of LiNbO3. That’s possible because the dielectric constant in polymer is intrinsically similar for light and the radio-frequency driver, so the two propagate at nearly the same speed, increasing device bandwidth, says Raluca Dino, vice president of Lumera’s electro-optic business unit. The difference in propagation speeds of optical and radio frequencies is much larger in LiNbO3, limiting its bandwidth. The faster the modulator, the shorter it must be to keep the optical and radio frequencies in phase, but the higher the drive voltage must be to provide the required phase shift over the shorter distances.

Lumera’s commercial devices so far are limited to polymers with r33 of 100 pm/V, so they can be sure their devices meet user lifetime requirements. Polymer attenuation is higher than the 0.2 dB/cm of LiNbO3 but Dino says the polymer’s higher nonlinearity offsets that by allowing shorter devices. The best laboratory results so far are around 450 pm/V, and DARPA has set its goal as 1200 pm/V.Multiphoton 3-D microfabrication

Chemists also have tailored multiphoton absorption cross section-a third-order nonlinearity-increasing it by about two orders of magnitude for the best organic materials. That has opened the door to the use of two-photon absorption for a new type of three-dimensional microfabrication. A laser beam is focused to a sharp point in a medium containing 0.1% to 2% of molecules with a high cross section for two-photon absorption. Simultaneous absorption of two photons excites the molecule to a state that initiates polymerization in the small region around the molecule. The process is highly localized because the probability of two-photon absorption falls off as the fourth power of distance from the focal spot.Today’s rapid-prototyping techniques depend on the deposition of many successive layers, which works well for solid 3-D objects. However, producing microstructures with that approach “is absolutely painful,” says Seth Marder of Georgia Tech (Atlanta, GA), because it requires elaborate procedures to deposit layers and remove sacrificial material in the hollow areas. He and Georgia Tech colleague Joe Perry have developed a two-photon process that writes microstructures by focusing laser light in three dimensions, building up a microstructure such as a photonic crystal, a textured surface, or a nanoscale linked chain.1 “You write the cross-linking layer by layer, but you don’t remove the material until everything is written,” says Marder. He and Perry recently demonstrated fabrication of photonic-crystal structures with internal structures only 65 nm thick (see Fig. 2).2

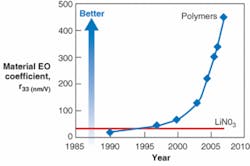

Multiphoton absorption also can be used for other applications, including all-optical signal processing and optical power limiting. For optical signal processing, the goal is for one optical signal to manipulate another, with the nonlinear material facilitating the interaction between photons. In the case of optical power limiting, the nonlinear nature of two-photon absorption causes the fraction of incident photons to decrease as the input power increases, so the transmitted power eventually reaches a limit (see Fig. 3). Nonlinear effects react virtually instantly, far faster than photochromic materials, making them suitable for protecting sensors from optical overload and eyes from laser beams. Such applications are among the targets of DARPA’s “Supermolecular photonics engineering” program (see www.arpa.mil/mto/programs/morph/index.html).

Birefringence and other applications

Birefringence has also been demonstrated in organic materials, although the birefringence value Δn was lower than the 0.172 of commercial calcite until recently. Now Daniel Leznoff’s group at Simon Fraser University (Barnaby, BC, Canada) has synthesized a family of coordination polymers with birefringence as high as 0.43 at 546 nm.3 “The material can be used in any application for which other birefringent solids such as calcite now play a role,” says Leznoff, with the higher birefringence allowing smaller devices. Properties of the materials can be changed by adjusting the flexible synthesis process, unlike calcite, where properties are fixed by the nature of the crystal. That allows selecting operating wavelengths. Samples have remained stable in the laboratory for months, and to temperatures of a few hundred degrees Celsius.

Many other concepts are in development. Focusing femtosecond laser pulses into nonlinear organic materials has generated short pulses at terahertz frequencies.4 Organic nonlinear materials also might find applications in biomedical imaging and sensing. Two-photon absorption is being investigated for photodynamic therapy. Organic photorefractive materials are being developed. The use of nonlinear organic materials in photonic crystals could allow wavelength tuning of their optical properties.

Outlook

Organic nonlinear materials clearly do have some limitations. Nobody expects them to match the temperature performance of inorganic crystals. Nor is there much interest in simple second-harmonic generation, which requires high optical power densities. Plenty of technical challenges remain.

But the real importance of organic nonlinear optics is not in simply replacing inorganic crystals in existing devices, writes Larry Dalton of the University of Washington. It is “in the stimulation of new applications and device concepts.”5 Examples range from integrating organic materials with silicon photonics to the development of new concepts such as two-photon lithography. There are likely to be more.

REFERENCES

1. S. Marder et al., MRS Bulletin 32, 561 (July 2007).

2. W. Haske et al., Optics Express 15, 3426 (March 19, 2007).

3. M.J. Katz et al., “Highly birefringent material designed using coordination polymer synthetic methodology,” Angewandte Chemie Int’l. Edition 46, 8804 (2007) (doi: 10.1002/anie.200702885).

4. A. Schneider et al., Optics Express 14, 5376 (June 12, 2006).

5. L. Dalton et al.,

![FIGURE 2. “Woodpile” photonic-crystal structures with different spacing were made with a two-photon absorption technique at Georgia Tech, viewed with a scanning-electron microscope. Top photos show the whole structures; bottom close-ups show details [2]. FIGURE 2. “Woodpile” photonic-crystal structures with different spacing were made with a two-photon absorption technique at Georgia Tech, viewed with a scanning-electron microscope. Top photos show the whole structures; bottom close-ups show details [2].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2016/01/th_0801lfw06f2.png?auto=format,compress&fit=max&q=45&h=192&height=192&w=250&width=250)