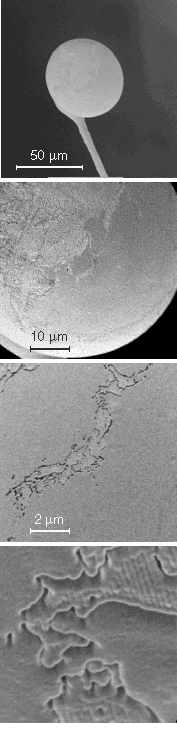

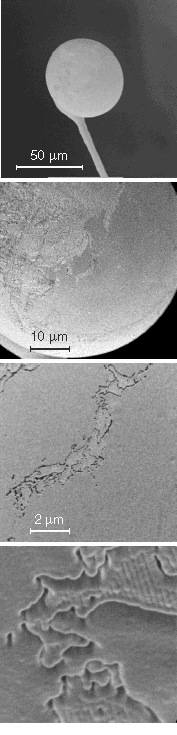

In a development that may one day help in the fabrication of nanometer-scale optical devices, engineers at Nippon Telegraph and Telephone Corp. (NTT: Tokyo, Japan) have created an electron-beam (e-beam) lithographic system that patterns features in three dimensions with minimum feature sizes of 10 nm. To demonstrate its capabilities, they fabricated the entire world in only two minutes.

Their task was made speedier by the fact that the globe they created was only 60 µm in size—the smallest rendition of the Earth's features ever made. Made of polymethylmethacrylate resin, the globe fully depicts Earth's geography, with land shaded and ocean left featureless.

The sample is held at the center of a small two-axis gimbal that, having the same shape as a semiconductor-wafer loader, can easily be removed from and reloaded into the e-beam apparatus. The gimbal can rotate about its first axis by 360° and about its second by 45°, and has an accuracy of 0.1°. To measure the position of the sample for proper lateral placement of the e-beam focus, a transmission-electron detector measures the outline of the sample's e-beam shadow.

Crucial to keeping the e-beam focused on the globe's surface is a confocal laser microscope that creates a height map of the globe at a 10-nm resolution, enabling the height of any point on the sample to be determined even when the sample is rotated. The system focus error is 1 to 2 µm.

These scanning-electron-micrograph images of the e-beam-patterned globe progressively zoom in from a whole-world shot to a portion of Japan—the spot where the island of Hokkaido most closely approaches the Tohoku region of the mainland. The minimum fabricable feature size of 10 nm corresponds to a full-scale distance of 2 km. The diagonal shading in the bottom close-up image has ridges that are about 50 nm apart.

In addition to the globe, the NTT researchers have fabricated nanofilters with 30-nm holes spaced just over 100 nm apart. These filters were created by first using the e-beam to erode away most of a 10-µm-diameter resin sphere, leaving an open box-like shape, then patterning the pores into the sides of the box.