Precision Glass & Optics (PG&O; Santa Ana, CA) was chosen to manufacture and install four sets of 26 unique, black glass optical panels for the Laser Interferometric Gravitational Wave Observatory (LIGO; http://www.ligo.org/science/GW-Detecting.php) that will be used to reduce noise, or unwanted electronic signals, in the observatory detectors. The two large interferometers, collectively called LIGO, are located in Hanford, WA and Livingston, LA and are dedicated to the detection and measurement of cosmic gravitational waves for scientific research.

RELATED ARTICLE: Advanced Laser Interferometric Gravitational Wave Observatory dedicated

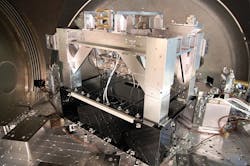

Each PG&O mirror panel was scribed and then machined on a waterjet to a tolerance of ± 0.010. Each part was subsequently laser engraved with the part number and serial number. The panels were thoroughly inspected for both visual and dimensional specifications before being meticulously cleaned before the coating process. To filter out excess noise, the parts were then coated with a thin-film broadband, anti-reflection, also called a BBAR coating (R < 0.5% at 1064 nm, with an angle of incidence at 0°). LIGO's output mode cleaner (OMC), where the specialty black glass from PG&O is installed, is intended to filter out light that does not potentially carry a gravitational wave signal.

According to LIGO systems engineer, Calum Torrie, "We are at a new frontier in astronomy: gravitational wave astronomy. The gravitational waves carry information about the motions of objects in our universe. LIGO utilizes Michelson interferometers whose mirrors are suspended as pendulums; these detectors will enable us to study the universe with a fresh set of eyes that do not depend on light."

Torrie continues, "We are delighted to announce the successful installation, which involved attaching AR-coated black glass panels from PG&O to the output mode cleaner suspension structure (and to the optics table beneath the OMC suspension). This permits us to surround and isolate the OMC from scattering paths to and from the surroundings, and from the reflective metallic surfaces of the optics table and the OMC."

Celebrating the company's 30th year, PG&O delivers precision glass, optics, and optical coatings for a variety of applications. Other services include CNC machining, polishing, slicing, sawing, scribing, grinding, edging, and assembly for military, aerospace, astronomy, biomedical, imaging, laser, digital cinema, solar markets, and more.

LIGO isfunded by the National Science Foundation (NSF) and designed and constructed by a team of scientists from California Institute of Technology (Caltech), the Massachusetts Institute of Technology (MIT), and industrial contractors.

SOURCE: PG&O; http://pgo.com/news-and-events