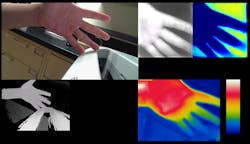

IMAGE:A composite image shows multiple sensing capabilities for the prototype medical sensing device developed by GE researchers with the U.S. Department of Veterans Affairs (VA) Center for Innovation. The device is now in testing with the VA to assess and monitor the progression of pressure ulcers, or bed sores. Here, a GE researcher captures an image of his hand to demonstrate the variety of image the device can show. Top-Left: Visual RGB Image; bottom-left: 3D Image; top-right: Multispectral Imaging and Recovered Feature Map and bottom-right: Thermal Imaging. Each of these provides insights to help assess whether a bed sore may be healing, getting worse, or becoming infected. (Image credit: GE Global Research)

A multi-disciplinary team of scientists at GE Global Research (Niskayuna, NY), the technology development arm for GE (NYSE: GE), have combined a stunning array of sensing and analytical capabilities, including motion analysis, thermal profiling, image classification/segmentation, 3D object reconstruction, and vapor detection into a single medical sensing device to assess and monitor the progression of pressure ulcers, or bed sores. The device, a handheld probe, was developed as part of a joint project with the U.S. Department of Veterans Affairs (VA) Center for Innovation aimed at eliminating pressure ulcers from forming during hospital stays.

RELATED ARTICLE: CMOS imager with mosaic filter detects skin disorders

Pressure ulcers are a common ailment that can develop for patients during long hospital stays. Individuals with spinal cord injuries with loss of mobility can be particularly at risk to develop bed sores. In U.S. hospitals alone, an estimated 2.5 million patients per year develop pressure ulcers, or bed sores, which require treatment. Of this number, > 60,000 end up dying from this disease and its complications.

"Pressure ulcers are a very pervasive, but also very preventable condition for hospital patients," said Ting Yu, principal investigator on pressure ulcer prevention and care program. "The device we have developed integrates multiple sensing and data analysis capabilities to help detect the earliest signs of ulcer formation. It also provides a more objective and comprehensive assessment of the wound to understand its progression. We’re now testing this device with the VA in a clinical setting to see if it provides the kind of information that will help hospitals reduce and even one day eliminates pressure ulcers from developing with patients."

"The collaboration with GE is another example of the innovative work VA is doing with our private sector colleagues to advance the science of health care for our Veterans," said Carolyn Clancy, VA's Interim Under Secretary for Health. "We are pleased to work with GE to pilot a technology that holds promise of revolutionizing the protocol for preventing and treating painful pressure ulcers. We know that if patients are not turned on a regular basis, they can develop bed sores during their hospital stay as pressure builds up on their skin. By combining physical inspection with the technology capable of allowing real-time monitoring, may prevent ulcers from forming or advancing. This innovation is about providing the best care to our Veterans and collaborations like this one with GE helps us do just that."

The prototype handheld probe GE scientists built is now being pilot tested at the Augusta VA Medical Center with 18 already consented patients in the Center's Spinal Cord Injury (SCI) Unit. The probe integrates multiple sensing capabilities with analytics and user support features to more acutely measure pressure ulcer formation or to determine if a formed ulcer is healing.

The features of the probe include:

Thermal sensor – measures the temperature profile within and around the ulcer. An elevated temperature could indicate the onset of an infection or if the temperature elevation is around the peripheral of the wound, indicate that healing is occurring.

RGB sensor – can help characterize the visual color and texture pattern of the ulcer, providing quantitative analysis of the wound tissue composition.

3D sensor – allows the detailed capture of 3D geometric shape of the wound, enabling more objective quantification of wound dimension changes over time.

Chemical sensor – can help detect the vapors release from the ulcer, where abnormal readings can indicate certain types of bacteria and infection.

Hyperspectral sensor – helps quantify the oxygenated hemoglobin, de-oxygenated hemoglobin and their ratio in the skin area. The monitoring of these quantities over time provides insight on ulcer healing or deterioration.

Situational awareness sensor – provides continuous 24×7 monitoring of patient positions in bed and his/her body movement. The derived metrics, for example, patient turning events in bed, if the event is enforced on a regular basis, will be critical to pressure ulcer prevention.

Decision Support – The analysis measures from sensing modalities are indexed into a centralized database, which is linked to a decision support dashboard web-portal, where clinical users can easily read out the comprehensive analysis.

SOURCE: GE Global Research; http://www.geglobalresearch.com/news/press-releases/ge-scientists-develop-multi-sensing-handheld-probe-to-assess-and-prevent-pressure-ulcer-formation-during-hospital-stays