Vertical-cavity surface-emitting laser (VCSEL) specialist Princeton Optronics (Mercerville, NJ) has introduced a high-power 8-W VCSEL array for illumination; the array, which is designed for ultrahigh reliability, emits at an 860 nm wavelength and has a specified mean time to failure (MTTF) of greater than 100 years at a 70 °C temperature and an electrical-to-optical (wall-plug) efficiency of greater than 40% at 60 °C.

Princeton Optronics makes high-power single- and multimode VCSELs and VCSEL arrays emitting in the IR and visible that are used for illumination, metrology, and solid-state-laser pumping.

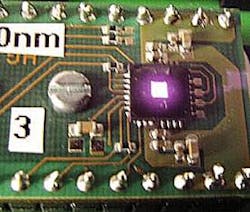

The reliability specs for the new VCSEL array are achieved through improved device processing and a new chip-on-submount mounting technology, according to Princeton Optronics. The device is directly surface-mountable on printed circuit boards (PCBs) and is suitable for high-volume manufacturing.

A key application of this device is as an illumination source for 3D sensing or imaging in computers, tablets, and cell phones. The VCSEL array can be used for either structured-light or time-of-flight (ToF) applications.

No hermetic seal necessary

The arrays can be packaged in a variety of configurations for high-volume applications, very similar to LEDs. They do not require a hermetically sealed housing, which reduces the packaging cost. Additionally, optics can be added to the package to create more options for beam handling in the illumination system incorporating the VCSEL array.

Princeton Optronics recently won approval for two patents for surface-mounted VCSELs for illumination applications, which the company says makes it uniquely positioned for this market.

For more info, see: www.princetonoptronics.com