Yurii Rezunkov from the Institute of Optoelectronic Instrument Engineering (Sosnovyi Bor, Russia) and Alexander Schmidt from the Ioffe Physical Technical Institute (Saint Petersburg, Russia) have developed a scheme to integrate a laser-ablation propulsion system with the gas nozzles of a rocket.1 Combining the two systems, the researchers found, can increase the speed of the gas flow out of the system to supersonic speeds and reduce the amount of burned fuel.

Currently, the maximum speed of a spacecraft is limited by the amount of solid or liquid fuel that it can carry. Achieving higher speeds means that more fuel must be burned—fuel that, inconveniently, has to be carried by the craft into space. These burdensome loads can be reduced, however, if a ground-based laser were used to provide additional propulsive force.

A number of systems have been proposed that can produce laser propulsion. One of the most promising involves laser ablation, in which a pulsed laser beam strikes a surface, heats it up, and burns off material to create a plasma plume. The outflowing of that plasma plume generates additional thrust to propel the craft.

Getting rid of instabilities

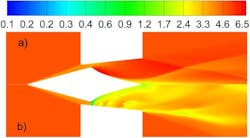

The Russian researchers have shown that the effectiveness of current laser-propulsion techniques is limited by factors including the instability of supersonic gases as they flow through the gas nozzle, as well as the production of shock waves that “choke” the inlet of the nozzle, reducing thrust. But those effects can be reduced with the help of a laser-ablation plasma plume that is redirected so that it will flow close to the interior walls of the nozzle. Coupling the ablation jet with supersonic gas flow through the nozzle, they find, significantly improves the overall thrust generated by the nozzle.

Their design is a supersonic version of the "Lightcraft" design developed by Leik Myrabo of the Rensselaer Polytechnic Institute (Troy, NY) and colleagues at NASA more than a decade ago, which in supersonic operation tended to produce deleterious nonuniform gas flow due to a shock wave generated in the laser-breakdown region. The Russian design avoids that problem by relying on the creation of a laser-ablated jet generated close to the rocket nozzle's inner walls.

Numerical modeling shows a resulting momentum-coupling coefficient (an efficiency measure applied to laser-propulsion systems of all types including air. space, and underwater) of 10-3 N/W, or 100 dyne/W.

“Summarizing the data obtained, we can forecast the application of the supersonic laser propulsion techniques not only for launching small satellites to Earth orbits but also for additional acceleration of supersonic aircrafts to achieve Mach 10 and more,” says Rezunkov.

REFERENCE:

1. Y. Rezunkov and A. Schmidt, Applied Optics, Vol. 53, Issue 31, pp. I55-I62 (2014); http://www.opticsinfobase.org/ao/abstract.cfm?URI=ao-53-31-I55.