Synthetic diamond supermaterials manufacturer Element Six, a member of the De Beers Group of Companies, was selected by the European Commission's Seventh Framework Programme for Research and Technological Development to help develop a new ultrafast pulse disk laser. The new ultrafast laser will be designed with high average output power to increase productivity and precision in micromachining of transparent materials.

RELATED ARTICLE: Synthetic diamond offers much more than heat sinking

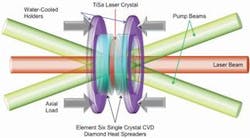

As part of the three year project titled “Ultrafast High-Average Power Ti:Sapphire Thin-Disk Oscillators and Amplifiers” (TiSa:TD), Element Six will further develop its low-loss, high purity single crystal chemical vapor deposition (CVD) diamond material to rapidly conduct heat off a titanium sapphire (TiSa) thin-disk, which will be used as the laser gain material. These developments will include increasing the areas available to Element Six customers.

Currently, most powerful industrial "ultrafast" lasers operate in the picosecond range, which offers sufficient performance for micromachining metals. However, the consortium aims to develop a new femtosecond laser system that allows extremely high precision with higher powers than previously achieved, in order to increase productivity for the micromachining of transparent materials such as glass and ceramics, commonly used in smartphones and tablets. Specifically, collaborators on this project are working to design two high-average power ultrafast TiSa thin-disk laser systems, one amplifier system using chirped pulses to obtain high-energy pulses, and one high-power oscillator to achieve high repetition rates. Both will have a maximum average output power of at least 200 W at a pulse duration of well below 100 fs.

To achieve these goals, TiSa will be used as the laser crystal material, which is optimal for short-pulse laser systems due to the broad bandwidth of its emission, yet lacks good thermal properties. To combat this challenge, Element Six will further develop its single crystal CVD diamond to be mounted to the TiSa as a heat spreader, improving its thermo-optical effects and allowing it to be pumped at the required higher powers.

"The low-loss single crystal CVD diamond material produced by Element Six offers a unique combination of properties--including the highest room temperature thermal conductivity of any bulk material--allowing it to be used as a transparent heat spreader inside the resonator of high-power thin-disk lasers, generating heat flow densities that cannot be handled with other materials," said the project lead, Andreas Voss of the Universität Stuttgart.

While Element Six's CVD diamond already has a thermal conductivity of up to 2200 W/mK as well as low birefringence and absorption rate, for this laser system application to be successful, further reductions in absorption coefficient of the CVD diamond and an increase in available area will be needed. "To date, our CVD diamond material has been leveraged for a range of commercial solid state laser systems with great success demonstrating unparalleled levels of heat extraction--enabling laser systems to operate at higher powers with improved beam quality," said Adrian Wilson, director of the technologies group at Element Six. "For TiSa thin-disk, we have been called upon to further improve our existing crystal CVD diamond, extracting additional value--and we are determined to meet expectations."

Other partners collaborating on TiSa thin-disk include the University of Stuttgart, the Centre National de la Recherche Scientifique, Thales Optronique, Oxford Lasers, and M-Squared Lasers.

SOURCE: Element Six; http://www.e6.com