To create optical fibers that transmit stable, high-power UV laser light for hundreds of hours, researchers at the National Institute of Standards and Technology (NIST; Boulder, CO) are treating the fibers with hydrogen to prevent solarization, a damage mechanism that can cause the transmission to drop to zero in a matter of hours.1 The NIST scientists expect these hydrogen-treated fibers to reduce errors in logic operations in their quantum-computing experiments.

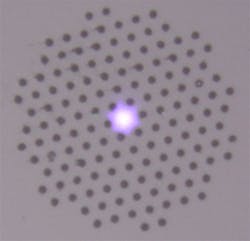

Two types of solid-core microstructured fibers were tested. The fiber-lattice air holes were infused with hydrogen gas at 100 times standard atmospheric pressure for four to six days. After the hydrogen diffused into the fiber cores, the fibers were cured by exposure to UV laser light for several days.

The researchers then tested the fibers by transmitting UV laser light through them. The fibers did not display any solarization damage, even at output powers as high as 125 mW at 313 nm laser wavelengths—several times the beam intensity needed for the group's quantum-computing experiments.

Long-term resistance to solarization

The combination of hydrogen infusion and curing with UV light "appears to confer long-term resistance" to this type of damage, according to the paper. For comparison, NIST researchers also tested fibers that were not treated with hydrogen. With 313 nm wavelength laser light at a power of 100 mW power, light transmission through the fibers dropped to zero in four hours, confirming the value of the hydrogen treatment.

The treated fibers could be used to transmit a wide range of IR, visible, and UV wavelengths. When used at NIST to transmit laser light to trap ions, the fibers reduce stray light and laser beam-pointing fluctuations and make it possible to transfer UV light between separate optical tables, the paper notes. The fibers also can help "clean up" misshapen beams.

REFERENCE:

1. Y. Colombe et al., Optics Express (2014); doi: 10.1364/OE.22.019783