A group of French researchers has designed and fabricated small silicon (Si) Fresnel lenses that can simplify thermal infrared cameras and make them lower in cost.1 Although its resolution is not superb, the lens is good enough to reveal the presence of a person and some general features. Potential applications for the imager include more affordable surveillance, particularly for home use, the researchers say.

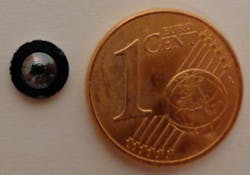

The lens has a thickness of 1 mm, an f/# of 1.5, and a diameter of just under 4 mm, with the Fresnel surface on the inner (image-facing) side. The lens stop is placed a bit less than 1 mm in front of the lens at approximately the telecentric position, with the result that edge-of-field rays with a 65° incidence angle are focused by a region of the lens near its edge that hardly overlaps with the lens region focusing the rays with 0° incidence angle. (And of course the chief rays are all parallel to the optical axis due to telecentricity.)

Importantly, the lens is achromatic over a spectral range of 7 to 14 μm, with the Fresnel surface largely compensating for the dispersion of Si over that range. While Si does not have wonderful transmission over this spectral range, the thinness of the lens allows adequate transmission of light.

The authors say their thin lens design could be a breakthrough in lowering the cost of thermal IR camera lenses by using materials that are cheaper than traditional ones such as germanium and chalcogenide. The researchers are based at ONERA and Institut d’Optique, CNRS (Palaiseau, France) and ULIS (Veurey-Voroize, France).

An unusual form of Fresnel lens

Fresnel lenses conventionally come in two forms: 1) a "lighthouse" form, which has relatively large individual zones and is only concerned with focusing via refraction (this version has relatively small dispersion due only to the refractive material); and 2) a diffractive version (usually called a "Fresnel zone plate"), which has zones small enough to focus via precisely stepping the phase of light to produce diffractive focusing (this version has a much larger dispersion due to the spectral nature of diffraction itself).

The new Si lens is an intermediate between the lighthouse and diffractive Fresnel lens styles. The researchers found that by increasing the depth of the lens' concentric rings and decreasing their number, they could reduce the diffractive lens' chromatic effects to a tolerable level. In tests of the image quality of their prototype, the team found that the image brightness and sharpness uniformity was good enough for a 130-degree ultrawide-field-of-view imager. They demonstrated that their camera can provide usable images of people inside an office, for example, after commonly used digital post-processing corrections for nonuniformity and distortion were applied to the image.

The design has been patented, but further work remains to make it marketable at a truly affordable price, says lead author Tatiana Grulois, a Ph.D. candidate at ONERA. The Si lens, with its 50-μm-deep features, was fabricated using direct diamond turning; by finding cheaper ways to manufacture the lenses (for example, using photolithography or molding of the appropriate materials) Grulois says her team hopes to reduce the cost of fabricating the optics and drive down the price of the whole imager.

REFERENCE:

1. T. Grulois et al., Optics Letters, Vol. 39, Issue 11, p. 3169 (2014); http://dx.doi.org/10.1364/OL.39.003169