Researchers from North Carolina State University (NC State; Raleigh, NC) and Wagner College (Staten Island, NY) have developed a processing technique that makes gallium nitride (GaN)-based LEDs not only more efficient, but more stable in in-situ environments such as biological tissue, making such devices more viable for use in biomedical applications such as implantable sensors, according to Stewart Wilkins, a Ph.D. student at NC State and the lead researcher.1

Self-assembling layer

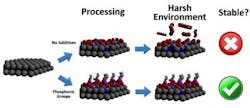

The process consists of coating the semiconductor material with a layer of phosphorus-derived acid. “By coating polar GaN with a self-assembling layer of phosphonic groups, we were able to increase luminescence without increasing energy input,” says Wilkins. “The phosphonic groups also improve stability, making the GaN less likely to degrade in solution."

After etching the GaN using a combination of phosphonic acid and phosphoric acid, the affected GaN surface was characterized using a variety of techniques, including atomic-force microscopy (AFM), x-ray photoelectron spectroscopy, photoluminescence (PL), inductively coupled plasma-mass spectrometry, and analyzing the water contact angle. The phosphoric acid increased luminescence, while the phosphonic groups self-assembled into a monolayer on the surface of the material. This layer further increased luminescence and improved the stability of the GaN by making it less likely to react chemically with its environment.

Source: http://news.ncsu.edu/releases/wms-ivanisevic-phosphonic2014/

REFERENCE:

1. S. J. Wilkins et al., Langmuir, published online February 2014; doi: 10.1021/la404511b