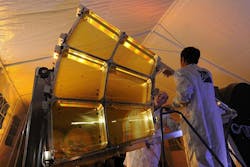

IMAGE: Ball Aerospace is demonstrating technology needed to deploy a large, 20 m diameter, lightweight space-based telescope in geosynchronous orbit as part of the MOIRE program led by DARPA. (Image credit: Ball Aerospace & Technologies)

Boulder, CO--Using ultra-lightweight polymer membrane optics, Ball Aerospace & Technologies has demonstrated unprecedented telescope technology needed to deploy a large, 20 m diameter, lightweight space-based telescope in geosynchronous orbit as part of the Membrane Optic Imager Real-time Exploitation (MOIRE) program, led by the Defense Advanced Research Projects Agency (DARPA).

Most recently, Ball completed construction and testing of one-eighth of a 5 m diameter annular segmented telescope to verify functionality of the MOIRE design. "The ground demonstration substantiates that this innovative technology could work on next generation space telescopes to greatly reduce their costs and enable larger telescopes," said Ball Aerospace president Rob Strain. "This technology could apply to a wide-range of applications - to provide various forms of information to a multitude of users."

The lightweight optics developed under the MOIRE program reduces the mass of large aperture telescopes by nearly an order of magnitude compared to those with conventional optics. Since costs scale roughly with spacecraft mass, one key to affordability is minimizing the mass of future space optics. This technology could lend itself to easily stowed configurations for launch within a payload shroud that could be deployed on orbit. The telescope concept that Ball developed employs thin (less than 1/1000th of an inch) transparent membranes etched with a diffraction pattern as the primary optical element used to focus light.

"This is the first design to use transparent membranes on a large scale," said Aaron Seltzer, director of advanced development for Ball Aerospace's National Defense business unit. "The result is a telescope with exceptionally low mass per unit of collecting area."

To produce MOIRE's optical-quality polymer membranes and the precision etching needed to generate the diffraction pattern, Ball worked with NeXolve and the Lawrence Livermore National Laboratory. The Ball demonstration telescope uses six primary diffractive optical elements (DOEs). Additional technologies demonstrated by Ball for the MOIRE telescope include the use of secondary DOEs to correct chromatic dispersion; stability of the membranes; and the use of laser metrology and active optics to align the primary and secondary optics.

Following the successful ground-based proof of concept for MOIRE, the Ball team intends to pursue additional funding to move the technology forward.

Ball Aerospace & Technologies supports critical missions for national agencies such as the Department of Defense, NASA, NOAA, and other U.S. government and commercial entities. The company develops and manufactures spacecraft, advanced instruments and sensors, components, data exploitation systems, and RF solutions for strategic, tactical, and scientific applications. Ball Corporation and its subsidiaries employ 15,000 people worldwide and reported 2012 sales of greater than $8.7 billion.

SOURCE: Ball Aerospace & Technologies; http://www.ballaerospace.com/page.jsp?page=30&id=556