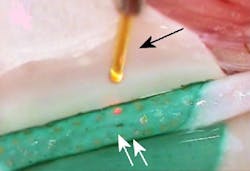

IMAGE: A chitosan patch infused with indocyanine green (ICG) dye wraps a rabbit carotid artery. A linear cut is repaired (white arrows) in laser-assisted vascular repair (LAVR). Laser spots (white arrowheads) are delivered by a 300 micron optical fiber (black arrow). (Image credit: SPIE Newsroom)

Sesto Fiorentino, Italy--Researchers from the Institute of Applied Physics in the National Research Council of Italy (IFAC-CNR) in Sesto Fiorentino, the Department of Neurosurgery at University Hospital Zurich (Zurich, Switzerland), and the Institute of Neurosurgery at Catholic University School of Medicine (Rome, Italy) have developed a laser-based tissue-soldering technique to improve neurosurgical microsutures.

Microsuturing, or delicate repair, of brain arteries is the gold standard for repair of surgical cuts and for rejoining small blood vessels (anastomosis), for example, in performing neurosurgical bypasses. The nature of brain surgery, with deep and narrow operative corridors, makes conventional microsuturing even more challenging. Conventional suturing methods are linked with several degrees of damage to blood vessel wall structures, which can cause a clot to form. In addition, the suturing procedure is slow, and it is necessary to stop the flow of blood through the vessel for its duration, which increases the risk of brain damage from a lack of oxygenated blood.

Laser-based suturing techniques potentially offer several advantages when compared to conventional methods, and a solution to this problem has been studied since the 1970s. One of the most promising approaches is laser welding with an 810 nm diode laser combined with application of a dye known as indocyanine green (ICG) to the area. The ICG mediates absorption of the laser light, and the resulting photothermal effect fuses the local tissue. However, the liquid formulation of ICG is partially optically degradable and spreads out over a large volume of tissue, thus failing to confine the welding procedure locally. To address this, the researchers have developed a laser soldering approach, based on a combination of the diode laser and a solid formulation of ICG and a biopolymer named chitosan.

They have designed and tested ICG-infused chitosan patches as soldering tools in laser-assisted vascular repair (LAVR) and laser-assisted vascular anastomosis (LAVA). The patches are resistant and stable in the physiological environment, and show enhanced optical stability over time compared to liquid ICG. The absorption peak is in the near-infrared (NIR) region. The patches can be used as a plaster, to cover a perforating wound. They use an NIR laser (an 810 nm diode equipped with a 300 micron diameter fiber core) to induce close adhesion between the tissue and the patch. They first deliver single laser pulses (100 J per square centimeter), keeping the fiber tip in contact with the outer layer of the patch, while the irradiated zone is kept hydrated. Then, continuous-wave laser irradiation (at 18 W per square centimeter) improves patch adhesion to the tissue surface.

The optimized laser soldering procedure was used to perform in vivo tests on a rabbit carotid artery. LAVR was carried out without the use of any stitches; the team joined two small blood vessels together end-to-end (LAVA) with only four single stitches. An immediate and effective closure was observed in all the treated samples, and wound closure was completed in quite a short and acceptable operative time. The strength of the vessels and their morphological characteristics were then studied at different follow-up times (for up to 90 days), by histological, immunohistochemical, and scanning electron microscopy analysis. All the treated vessels were perfectly sealed at follow-up. We found good healing of the blood vessel walls, with perfect restoration of the inner wall.

Next steps are to further optimize and standardize the procedure in preparation for a clinical study of its use.

SOURCE: SPIE Newsroom; http://spie.org/x104916.xml?highlight=x2416&WT.mc_id=KNRBIOMEDE