Stanford, CA--A low-cost, corrosion-free, silicon-based water splitter has been developed by Stanford University scientists. The device—a silicon semiconductor coated in an ultrathin layer of nickel—could help pave the way for large-scale production of clean hydrogen fuel from sunlight, according to the results published in the November 15 issue of the journal Science.

"Solar cells only work when the sun is shining," said study co-author Hongjie Dai, a professor of chemistry at Stanford. "When there's no sunlight, utilities often have to rely on electricity from conventional power plants that run on coal or natural gas." A greener solution, Dai explained, is to supplement the solar cells with hydrogen-powered fuel cells that generate electricity at night or when demand is especially high.

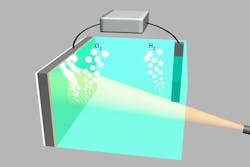

To produce clean hydrogen for fuel cells, scientists have turned to an emerging technology called water splitting. Two semiconducting electrodes are connected and placed in water. The electrodes absorb light and use the energy to split the water into its basic components, oxygen and hydrogen. The oxygen is released into the atmosphere, and the hydrogen is stored as fuel. When energy is needed, the process is reversed. The stored hydrogen and atmospheric oxygen are combined in a fuel cell to generate electricity and pure water.

The entire process is sustainable and emits no greenhouse gases. But finding a cheap way to split water has been a major challenge. "Silicon, which is widely used in solar cells, would be an ideal, low-cost material," said Stanford graduate student Michael J. Kenney, co-lead author of the Science study. "But silicon degrades in contact with an electrolyte solution. In fact, a submerged electrode made of silicon corrodes as soon as the water-splitting reaction starts."

In 2011, another Stanford research team addressed this challenge by coating silicon electrodes with ultrathin layers of titanium dioxide and iridium. That experimental water splitter produced hydrogen and oxygen for eight hours without corroding. "Those were inspiring results, but for practical water splitting, longer-term stability is needed," Dai said. "Also, the precious metal iridium is costly. A non-precious metal catalyst would be desirable."

To find a low-cost alternative, Dai suggested that Kenney and his colleagues try coating silicon electrodes with ordinary nickel. "Nickel is corrosion-resistant," Kenney said. "It's also an active oxygen-producing catalyst, and it's earth-abundant. That makes it very attractive for this type of application." For the experiment, the Dai team applied a 2 nm thick layer of nickel onto a silicon electrode, paired it with another electrode and placed both in a solution of water and potassium borate. When light and electricity were applied, the electrodes began splitting the water into oxygen and hydrogen, a process that continued for about 24 hours with no sign of corrosion. To improve performance, the researchers mixed lithium into the water-based solution. "Remarkably, adding lithium imparted superior stability to the electrodes," Kenney said. "They generated hydrogen and oxygen continuously for 80 hours—more than three days—with no sign of surface corrosion."

These results represent a significant advance over previous experimental efforts, added Dai. "Our lab has produced one of the longest lasting silicon-based photoanodes," he said. "The results suggest that an ultrathin nickel coating not only suppresses corrosion but also serves as an electrocatalyst to expedite the otherwise sluggish water-splitting reaction. "Interestingly, a lithium addition to electrolytes has been used to make better nickel batteries since the Thomas Edison days. Many years later we are excited to find that it also helps to make better water-splitting devices."

Support was provided by the Precourt Institute for Energy and the Global Climate and Energy Project at Stanford and the National Science Foundation.

SOURCE: Stanford University; http://news.stanford.edu/news/2013/november/nickel-water-splitter-111213.html