The iC-TW8 high-resolution signal processor evaluates sine/cosine sensors, minimizing angular errors and jitters with automatic functions. It can be used for initial, push-button calibration and to permanently adapt signal path parameters during operation. Angular position is calculated at a programmable resolution of up to 65,536 increments/input cycle and output as an indexed incremental signal.

iC-Haus

Bodenheim, Germany

http://ichaus.com

More Products

-----

PRESS RELEASE

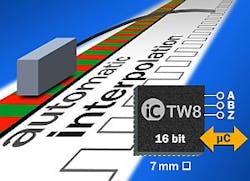

iC-TW8: Precision Interpolation Circuit for 16 bits with Automatic Correction

iC-TW8: High-Resolution Sine/Cosine Evaluation with Automatic Signal Error Correction

High-resolution signal processor iC-TW8 is used to evaluate sine/cosine sensors, minimizing angular errors and jitters with automatic functions. It is also utilized for initial, push-button calibration and to permanently adapt signal path parameters during operation. The angular position is calculated at a programmable resolution of up to 65,536 increments per input cycle and output as an indexed incremental signal. A 32-bit word including the counted cycles is available through the SPI.

As an application-specific DSP iC-TW8 has two analog/digital converters that sample simultaneously at a rate of 250 kSPS, fast CORDIC algorithms and special signal filters, and an analog front end with differential PGA inputs which accepts typical magnetic sensor signals from 20mVpp upwards. Signal frequencies of up to 125 kHz permit high rotary and linear speeds for position measuring devices and are processed at a constant latency period of 24 µs.

No measuring tools are needed to utilize the 12-bit measurement accuracy provided by the device; one press of a button is enough! The device learns the necessary signal corrections for the offset, amplitude, and phase errors independently, storing these in an external EEPROM. If these start values alone are not sufficient, for example with changes in amplitude or an offset drift across the temperature, permanent automatic corrections can be selected. In addition, for sine signals distorted by harmonics a table with 64 breakpoints allows the angular data to be statically corrected.

iC-TW8 provides incremental encoder quadrature signals of up to 8 MHz, where the maximum output frequency can be limited to guarantee countability across large edge distances. An analog or digital reference mark sensor, such as an MR, GMR, or Hall sensor, can be connected up for the electronically generated, programmable zero signal.

PWM signals and serial interfaces are provided for controller applications (1-wire interface, and an SPI interface for clock rates of up to 32 MHz). The 32-bit position register supplies the angle data and period count; a second register provides information on the current angular speed.

iC-TW8 has two configuration modes. Preset functions and interpolation factors can be retrieved through pins and the device calibrated at the push of a button. No programming is required for initial operation.

The device's full range of functions can be accessed when the serial interfaces are used. These are an AB output divider for fractional interpolation, an advanced signal filter to reduce jitter, a table for the compensation of signal distortion, and configurable monitors for errors and signal quality.

Typical applications are:

- Magnetic linear displacement measuring systems

- Optical linear scales

- Programmable magnetic/optical incremental encoders

- High-resolution absolute/incremental angle sensors with on-axis Hall scanning

- The general evaluation of sine/cosine signals (e.g. PC measuring cards for 1 Vpp, 11 µApp).

The device operates on a single-ended supply of +3.1 V to 5.5 V within an extended operating temperature range of -40 to +125°C. The only external device needed is an EEPROM for the calibration data; a quartz oscillator is optional.

Samples and production volume is available and can be ordered at $7.69 in quantities of 1.000 pcs.

iC-TW8 comes in a space-saving 48-pin QFN package and requires just 7 x 7 mm of board space. A ready-to-operate demo board is available for evaluation; an optional PC operating program (GUI) can be connected up using a USB adapter.

Further information is available at http://www.ichaus.com/product/iC-TW8

Introducing iC-Haus

iC-Haus GmbH is a leading independent German manufacturer of standard iCs (ASSP) and customized ASiC semiconductor solutions. The company has been active in the design, production, and sales of application-specific iCs for industrial, automotive, and medical technology for over 25 years and is represented worldwide.

The iC-Haus cell libraries in CMOS, bipolar, and BCD technologies are fully equipped to realize the design of sensor, laser/opto, and actuator ASiCs, among others.

The iCs are assembled in standard plastic packages or using the iC-Haus chip-on-board technology to manufacture complete microsystems, multichip modules, and optoBGATM, the latter in conjunction with sensors.

Further information is available at http://www.ichaus.com.

-----

Follow us on Twitter

Subscribe now to Laser Focus World magazine; it's free!