A family of mini-bar lasers has 915, 940, 955, and 976 nm versions, all of which contain five 90-μm-wide emitters with 1000 μm spacings and deliver 55 W output power. They serve as pumping sources for fiber and solid-state lasers as well as for direct-diode applications. The laser bars, when mounted on a passive heatsink, deliver 66% efficiency at 80 W output power.

Jenoptik Laser & Materials Processing Division

Jena, Germany

www.jenoptik.com

More Products

-----

PRESS RELEASE

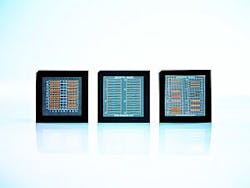

More efficient laser material processing with the new single emitters and semiconductor lasers from Jenoptik.

Jenoptik's Laser & Materials Processing Division presents its new semiconductor lasers with an even higher efficiency rate. They can be seen at this year's LASER World of PHOTONICS from May 13 to 16 bis May 16, 2013 at Booth 320 in Hall C1 of Messe Muenchen ICM, Germany.

The new semiconductor lasers from Jenoptik are the perfect pumping sources for fiber lasers and disk lasers. Due to their high efficiency of over 70 percent with very little beam divergence, they guarantee high output power and high brilliance along with long life and low cost.

The 9xx nanometer (nm) single emitters with 90 micron (µm) aperture have 12 Watt (W) output. The efficiency at this output level and a mounting on a passive heat sink, is 64 percent. The highest obtainable efficiency is 74 percent. The beam divergences of 26° in fast axis and 6.5° in slow axis direction (full width half maximum of the peak at 12 W) makes them ideal for coupling in a 105 µm fiber.

The 9xx nm mini-bars are a perfect beam source: they combine the high brilliance of the single emitters with the low mounting costs of the bars. The mini-bars contain five emitters of 90 µm width and 1000 µm spacing each. With maximum 55 W output power and being mounted on a passive heat sink, the highest efficiency is 69 percent. The beam divergences are the same as those of the single emitters.

The new laser bars are available for wavelengths of 915, 940 and 955 nm and (with low filling factor) of 976 nm. They are ideal pumping sources for fiber and solid-state lasers, but also a very good solution for diode direct applications.

The higher efficiency is particularly evident from the full bars for 976 nm with a filling factor of 20 percent. These bars, mounted on passive heat sink, score 66 percent efficiency at 80 W output power. The beam divergences at this output level are 23° in fast axis direction and 6.5° in slow axis direction (full width half maximum of the peak). The degree of polarization of these TE-polarized lasers is better than 97 percent.

The bars for 938 nm wavelength and 50 percent filling factor have been improved for the optical pumping of disk lasers. Mounted on passive heat sink, their efficiency is 64 percent at 200 W output power; at 250 W output power the efficiency is still over 60 percent.

All semiconductor lasers from Jenoptik are produced under strict process control and meet all requirements of highest quality, reliability and life time.

In addition to the new semiconductor lasers, other new and improved products will be shown alongside tried and tested solutions from all fields of laser material processing at the LASER Munich 2013 trade show.

About the Jenoptik Lasers & Material Processing division

With its Lasers & Material Processing division, Jenoptik is one of the leading providers of laser technology and provides products and solutions along the entire value-added chain of laser material processing â from components up to complete laser systems. In the Lasers business unit, the company has specialized in high-quality semiconductor lasers, reliable diode lasers as modules or systems as well as innovative solid-state lasers such as disk and fiber lasers. This product portfolio makes Jenoptik the ideal partner for the entire pulse width range, from cw to fs. In the field of high-power diode lasers, the company is acknowledged as a worldwide quality leader.

In the Laser Processing Systems business unit, Jenoptik develops and manufactures laser machines which are integrated into its customersâ production lines as a part of their process optimization and automation. They serve for the processing of plastics, metals and glass in connection with the processing of thin films. Jenoptik laser systems ensure processing at maximum efficiency, precision and safety. In addition, customers can try out various laser sources and machines at the Application Centers, thus finding the optimal solution for their application. The product portfolio is rounded off with energy-efficient and environmentally friendly exhaust cleaning systems for residue-free removal of pollutants during laser processing and other industrial processes.

-----

Follow us on Twitter

Subscribe now to Laser Focus World magazine; it's free!