Columbus, OH--A once-promising approach for using next-generation, ultra-intense lasers to help deliver commercially viable fusion energy has been brought into serious question by new experimental results and first-of-a-kind simulations of laser-plasma interaction conducted by researchers at The Ohio State University. The researchers are evaluating a two-stage Fast Ignition process in which a pellet of fusion fuel (http://www.laserfocusworld.com/articles/2012/07/nif-500-tw-to-fusion-target.html) is first crushed by lasers on all sides, shrinking the pellet to dozens of times its original size, followed by an ultra-intense burst of laser light to ignite a chain reaction.

In a recent Physical Review E paper at http://pre.aps.org/abstract/PRE/v86/i6/e065402, the Ohio State research group considered the long-discussed possibility of using a hollow cone to maintain a channel for the ultra-intense "ignitor pulse" to focus laser energy on the compressed pellet core. Drawing on both experimental results from studies at the Titan Laser at Lawrence Livermore National Laboratory (Livermore, CA) and massively-parallel computer simulations of the laser-target interaction performed at the Ohio Supercomputer Center (OSC; Columbus, OH), the research team found compelling evidence that the cone-guided approach to Fast Ignition has a serious flaw.

Since the ultra-intense pulse delivers energy to the fuel through relativistic electrons accelerated by the laser interaction, the Ohio State study focused on the coupling of the laser light to electrons and the propagation of those electrons through the cone target. Rather than investigating how the interaction would work on a high-demand, high-cost facility like the National Ignition Facility (NIF), the researchers considered experiments just across from NIF at the Titan laser, which is much smaller and easily accessible.

Despite its size and despite having lower total energy, for a brief moment the Titan laser is many thousands of times more intense than NIF, which makes it a decent stand-in as a second-stage ignitor pulse. The OSU-led experimental team focused the Titan pulse on hollow cone targets attached at the tip to copper wires and observed the burst of X-ray photons coming from the copper as a measure of the laser energy to relativistic electron conversion efficiency.

The X-ray signal was much lower from the hollow cones with thicker cone walls. "This was strong evidence to the experimental team that the typical approach to cone-guided Fast Ignition wouldn’t work, since thicker cones should be more realistic than thin cones," said Chris Orban, a researcher of the High Energy Density Physics research group at Ohio State and the lead theorist on the project. "This is because electrons are free to move around in a dense plasma, much like they do in a normal metal, so the thicker cone target is like a thin cone embedded in a dense plasma."

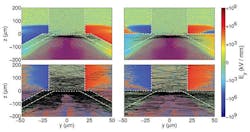

These intuitions were tested in simulations performed at OSC. Whereas earlier efforts to simulate the laser-target interaction were forced to simplify or shrink the target size in order to make the calculations more feasible, Orban used the LSP code to perform the first-ever, full-scale 2D Particle-In-Cell simulations of the entire laser-target interaction using fully realistic laser fields.

These simulations also included a sophisticated model for the pre-heating of the target from stray laser light ahead of the ultra-intense pulse developed by collaborators at the Flash Center for Computational Science at the University of Chicago.

To conduct the simulations, the Ohio State researchers accessed OSC's flagship Oakley Cluster supercomputer system. The HP-built system features 8,300+ Intel Xeon cores and 128 NVIDIA Tesla GPUs. Oakley can achieve 88 teraflops, tech-speak for performing 88 trillion calculations per second, or, with acceleration from the NVIDIA GPUs, a total peak performance of 154 teraflops. "The simulations pointed to the electric fields building up on the edge of the cone as the key to everything," said Orban. "The thicker the cone is, the further away the cone edge is from the laser, and as a result fewer energetic electrons are deflected forward, which is the crucial issue in making cone-guided Fast Ignition a viable approach."

With both the experiment and the simulations telling the same story, the evidence is compelling that the cone-guided route to Fast Ignition is an unlikely one. While other studies have come to similar conclusions, the group was the first to identify the plasma surrounding the cone as a severe hindrance. Thankfully, there are still many other ideas for successfully igniting the fusion pellet with current or soon-to-be-constructed laser facilities. Any future efforts to spark fusion reactions with these lasers using a two-stage fast-ignition approach must be mindful to consider the neutralizing effect of the free electrons in the dense plasma.

SOURCE: The Ohio State University; https://www.osc.edu/press/simulations-uncover-obstacle-to-harnessing-laser-driven-fusion