LS2-6140 optically clear, primerless silicone encapsulant offers strong adhesion to ceramic and common plastics used for electronic components. The elastomer has a 45 Type A durometer and is optically stable with a refractive index of 1.40. It can be used on components that will be exposed to high lumen intensity at elevated temperatures.

NuSil Technology

Carpinteria, CA

www.nusil.com

-----

PRESS RELEASE

NUSIL TECHNOLOGY INTRODUCES TWO NEW SILICONE MATERIALS FOR POTTING AND ENCAPSULATING

New versatile silicones provide durable support and protection in electronic and photonic applications.

Carpinteria, California - NuSil Technology LLC (http://www.nusil.com), a global leader in silicone materials for the medical implants, aerospace, electronics and engineering markets, officially debuted two new silicone products. NuSil's Engineering and Electronics business unit has developed LS2-6140, an optically clear primerless encapsulant, and R-2175, a flowable, thermally stable potting compound, as part of concentrated efforts to increase market specialization in the fast-paced industries sectors it serves.

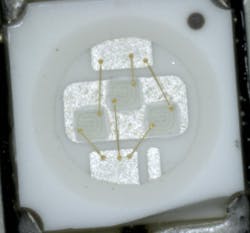

LS2-6140 is a low viscosity, optically clear silicone encapsulant that offers strong adhesion to ceramic and common plastics used for electronic components without the need for primer. This versatile elastomer has a 45 Type A durometer and is optically stable with a refractive index (RI) of 1.40. Ideal for use in High Power and UV LED applications, it can be used to bond or encapsulate optical components that will be exposed to high lumen intensity at elevated temperatures. The low viscosity of LS2-6140 allows for processing by way of spin coating, dispensing, casting or compression molding.

R-2175 is a black, pourable, versatile silicone potting compound adept at providing support for electronics packages such as power supplies, sensors, and AC/DC and DC/DC high efficiency convertors. Its rheology yields a conformal material that works well with complex geometries and its 0.4 W/mK thermal conductivity helps dissipate heat. R-2175 comes in a variety of packaging configurations to ease transition into any manufacturing environment.

"LS2-6140 and R-2175 are unique materials designed to support and protect photonic and electronic systems," said Bob Umland, Marketing & Sales Director - Electronics & Engineering. "NuSil's business unit for Engineering, Electronics, and Photonics is expanding silicone technology offerings to meet the growing needs of these industries."

LS2-6140 and R-2175 have been tested per UL 94 and passed V0 and are REACH and ROHS compliant.

For more information, please contact NuSil at +1 805-684-8780 or visit http://www.nusil.com/products/index.aspx.

###

About NuSil Technology LLC

NuSil is a leading manufacturer of silicone compounds for the medical implants, healthcare, aerospace & defense, electronics & engineering and skin care markets for applications requiring precise, predictable materials performance. ISO 9001-certified since 1994 and AS 9100-certified since 2008, NuSil operates state-of-the-art laboratories and processing facilities in North America and provides on-site, in-person application engineering support worldwide. More information about NuSil Technology LLC can be found at http://www.nusil.com.

-----

Subscribe now to Laser Focus World magazine; it's free!