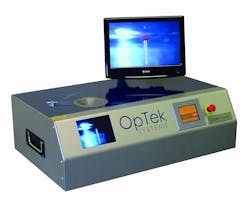

LaserCleave is a production-ready platform from OpTek Systems for noncontact optical fiber cutting for optical connector and component manufacture. It is designed to cut fiber and epoxy close to the ferrule face, and is offered in single- and multifiber formats. A patented process produces an optical-quality finish on flat endfaces at angles from 0° to >45°.

AMS Technologies

Martinsried, Germany

www.amstechnologies.com

-----

PRESS RELEASE

LaserCleave™ from OpTek Systems is a compact, production-ready platform for non-contact, optical fiber cutting and is designed to maximize productivity in optical connector and component manufacture.

LaserCleave™ production tools are built around the same OpTek technology that has been relied upon in performance critical, volume production of fiber optic components since the 1990's. The core values of the laser Cleave are the elimination of mechanical scribing and the reduction of polishing steps required for connector finishing.

The base model of the laser cleave product family is designed to cut fiber and epoxy on a single fiber connector ferrule prior to conventional polishing.

The single fiber ferrule models are designed to minimize the number of polishing steps required to finish the connector by cutting close to the ferrule face, with a profile that prevents unnecessary damage to the polishing films.

For single fiber ferrules with low to moderate epoxy bead size the LaserCleave-SSP produces and end that can be polished in a single step with finishing film.

The range will also accommodate multi-fiber ferrules such as the MT, plus free fibers,ribbon and stubs.

OpTek’s unique machine tools are in service around the world producing laser-processed fiber ends of unmatched quality and reproducibility, with many millions of OpTek-processed ends in service in telecoms, datacoms, medical, aerospace and defense applications.

Simplex

OpTek’s unique patented process produces a superior optical quality finish on flat end-faces. At angles from zero degrees to in excess of 45 degrees.

Ribbon

Rapid processing of ribbons in a range of geometries with excellent fiber-to-fiber registration.

Ferrule

Optimized for cutting through fiber and epoxy close to mechanical constraints such as ferrules with protrusion lengths of less than 40m.

APPLICATIONS

Cut fiber & epoxy

Close for ferrule face

Rapid non-contact process

Single and multi-fiber formats

-----

Subscribe now to Laser Focus World magazine; it's free!