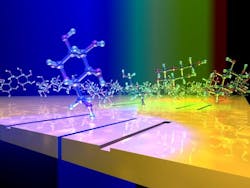

Providence, RI--A new technique from researchers at Brown University that takes advantage of a convergence of nanotechnology and surface plasmonics can measure blood sugar levels by measuring glucose concentrations in saliva rather than blood, saving the 26 million Americans alone living with diabetes the painful process of drawing blood. The engineers etched thousands of plasmonic interferometers onto a fingernail-size biochip and measured the concentration of glucose molecules in water on the chip. Their results showed that the specially designed biochip could detect glucose levels similar to the levels found in human saliva. Glucose in human saliva is typically about 100X less concentrated than in the blood.

"This is proof of concept that plasmonic interferometers can be used to detect molecules in low concentrations, using a footprint that is ten times smaller than a human hair," said Domenico Pacifici, assistant professor of engineering and lead author of the paper in Nano Letters. The technique can be used to detect other chemicals or substances, from anthrax to biological compounds, Pacifici said, "... and to detect them all at once, in parallel, using the same chip."

To create the sensor, the researchers carved a slit about 100 nm wide and etched two 200 nm-wide grooves on either side of the slit. The slit captures incoming photons and confines them. The grooves then scatter the incoming photons, which interact with free electrons on the sensor's metal surface and create a surface plasmon polariton. These surface plasmon waves move along the sensor's surface until they encounter the photons in the slit. This "interference" between the two waves determines maxima and minima in the light intensity transmitted through the slit and the presence of an analyte on the sensor surface generates a change in the relative phase difference between the two surface plasmon waves, which in turns causes a real-time, measurable change in light intensity.

The engineers learned they could vary the phase shift for an interferometer by changing the distance between the grooves and the slit, meaning they could tune the interference generated by the waves. The researchers could tune the thousands of interferometers to establish baselines, which could then be used to accurately measure concentrations of glucose in water as low as 0.36 mg per deciliter.

The engineers plan to build sensors tailored for glucose and for other substances to further test the devices. "The proposed approach will enable very high throughput detection of environmentally and biologically relevant analytes in an extremely compact design. We can do it with a sensitivity that rivals modern technologies," Pacifici said.

SOURCE: Brown University; http://news.brown.edu/pressreleases/2012/01/plasmonic