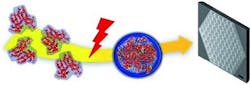

Changchun, China--Scientists at Jilin University have created adjustable microlenses made from protein gels, using femtosecond laser direct writing to create the lenses from bovine serum albumin.1 The lenses change size as a function of pH in the surrounding solution, allowing them to be focused.

In the process, methylene blue acts as a photosensitizer, triggering a crosslinking reaction in the protein molecules. Driven by a computer, the laser cuts out the desired 3D form voxel by voxel. The crosslinking reaction only takes place in the locations that are irradiated. After the reaction, the protein molecules that have not reacted can simply be rinsed away. What stays behind is a cross-linked, aqueous protein gel in the shapes of micrometer-sized lenses.

Direct writing with lasers usually results in structures that have too rough a surface for optical applications. By optimizing the duration of the laser pulse, the pulse intensity, and the protein concentration, Hong-Bo Sun and his team obtained lenses with outstanding optical properties.

Increasing the pH causes the lens to swell; if the increase in thickness is limited by a glass surface, the lens primarily grows in width and becomes flatter. If the pH value is reduced, the gel shrinks and the lens is more sharply curved. Because the protein lenses are biocompatible, they may be used in optical analytical systems for medical diagnostics or lab-on-a-chip technology.

Source: http://onlinelibrary.wiley.com/journal/10.1002/%28ISSN%291521-3773/homepage/2002_jour.html

REFERENCE:

1. Yun-Lu sun et al., Angewandte Chemie, Article first published online: 12 Dec. 2011; DOI: 10.1002/anie.201105925