JEAN-MICHEL PELAPRAT, MATTHEW FINUF, ROBERT FRITZ, and MARK ZEDIKER

Lasers are flexible tools capable of delivering energy to precise locations. Flexible and precise energy delivery is desirable for many industrial applications, but only if the amount of delivered energy is sufficient to get a task done. Welding, cutting, and cladding, for example, all are good candidates for industrial lasers. Until recently, however, only infrared (IR) lasers had sufficient power to be useful in these applications. NUBURU has now developed a new type of industrial laser, a high-power blue laser consisting of blue laser diodes coupled to an optical fiber (see Fig. 1). The first commercial product, called the AO-150, is a 150 W 450 nm laser source with its output coupled into a 200-µm-diameter optical fiber.

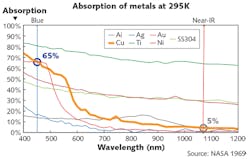

For many applications, blue lasers have several intrinsic advantages over their IR counterparts, primarily stemming from the enhanced absorption of many common industrial materials at shorter wavelengths (see Fig. 2). For example, welding of copper and many other metals is far more efficient at blue wavelengths than it is in the IR. Many materials used in additive manufacturing (3D printing) are also more efficiently processed at blue wavelengths.The fundamental physical advantages of blue light for materials processing are no secret, but its use for industrial applications had to await technological advances that enable high-power blue lasing.

Building into the blue

The advantages of welding using blue lasers stem from the fundamental physics of absorption. Those inherent advantages could have been exploited by any blue laser offering sufficient optical power to be productive. The missing piece had been the key technologies to make high-power blue lasers feasible.

The first essential element is the diode source itself. Gallium nitride (GaN)-based semiconductor technology has advanced rapidly, benefitting from the push toward general solid-state lighting and related applications. One example of this is a blue laser diode multi-die package (PLPM4 450) made by Osram (Regensburg, Germany) that combines 20 separate multimode diodes in a single package, offering a total output power >60 W. The AO-150 combines the separate outputs of each of the diodes from four independent packages. The individual beams are actively aligned in a semiautomated process.

Like all laser diodes, the output of each separate element is asymmetric, so each output is initially circularized with fast- and slow-axis collimators. These micro-optical elements are themselves a corollary development to the growth in diode technology. After collimation, the divergence of each beam is 1.5 × 4.3 mrad. The individual beams are then interleaved with a series of patterned mirrors to fill in the gaps from each of the chip modules. Additional macro-optics lead to a focused beam size of about 130 × 225 µm—too large for effective coupling into a 200 µm optical fiber.

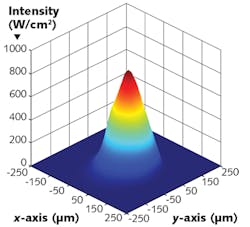

The beam is then further conditioned with a series of optical elements, including polarizing optics, a 2.5X cylindrical telescope, and an aspheric coupling lens. At the fiber entrance, the effective numerical aperture is 0.22 and the beam size is 125 × 129 µm. The result is an efficiency of nearly 95%, including both the coupling efficiency and the fiber losses. As shown in Figure 3, the output beam profile is well conditioned and highly symmetrical.Although the AO-150 design is capable of nearly 190 W continuous-wave (CW) operation, delivered systems are set to operate at an output power of 150 W to ensure long laser lifetime. A stable mechanical and thermal design, combined with closed-loop water cooling, produces an output beam with better than 3% power stability per 1000 hours.

The motivation for the attention to detail in this system engineering is the expectation that blue-wavelength lasers can outperform IR lasers for many industrial applications. Initial tests have demonstrated the validity of that expectation.

Welding copper

Copper is a crucial material in electronic devices. Making connections between copper elements is essential for the function of those devices. For high-volume products, such as consumer electronics and lithium-ion batteries, the large number of connections cries out for an efficient and flexible process such as laser welding.

Copper absorbs only about 5% of incident near-IR radiation—as a result, a great deal of IR laser power is necessary to initiate melting. Once melting is initiated, the keyhole absorbs a much higher percentage of the incident IR radiation. That means it’s very easy to deliver too much energy to the melt pool, resulting in spatter and voids. Simply put, too much absorbed energy creates a poor-quality weld, producing poor mechanical and electrical performance in the finished assembly. Infrared laser systems for copper welding must tread an almost impossibly thin line—a narrow process window in which enough energy must be delivered to initiate melting, but not so much energy that the melted copper instantaneously evaporates.

Copper absorbs blue light more than 10X as efficiently as it absorbs IR, which establishes a much wider process window.1 That is, the energy required to initiate melting is essentially the same as the energy needed to maintain the weld. This leads directly to higher-quality copper welding with blue lasers.

In addition to that qualitative advantage, blue lasers have a quantitative advantage. Various operational techniques have been developed to compensate for the poor performance of IR welding of copper; all of those operational methods increase the time required to execute a weld (and they still don’t generally succeed in producing high-quality welds with IR lasers). Blue lasers produce their high-quality copper welds at process speeds anywhere from 2 to 10X as quickly as IR lasers.

These advantages are clear for applications such as lithium-battery fabrication. The power of a battery depends upon the surface area involved in the chemical reaction, so lithium batteries maximize the surface area by incorporating many thin foil sheets together. Those individual copper foils need to be joined. The quality of the joint, however, must be very high. Ultrasonic welding is used to join these foils, but it requires contact with an ultrasonic welding head, which increases the minimum weld size and decreases manufacturing flexibility. In addition, ultrasonic welds produce unwanted particulates, creating a contamination problem that can form internal shorts and degrade battery performance. A 500 W version of the NUBURU laser called the AO-500, due to be introduced to the market later in 2018, has demonstrated void- and spatter-free welding of 40 10-µm-thick copper foils. A typical blue-laser foil weld is shown in Figure 4.Batteries also require joining of leads and busbars outside of the individual cell. Infrared laser welding can be used here, but the absorption problem induces vaporization and spatter, generating voids that reduce the electrical conductivity (and thus the battery efficiency). Again, the improved absorption at blue wavelengths and the process control possible with a very stable laser output eliminates vaporization and spatter.

Beyond copper

These same kinds of advantages extend to many other metals besides copper. In addition, blue lasers have demonstrated an ability to address the challenging problem of welding dissimilar metals. One of the problems with welding dissimilar metals is the difference in their light absorption and thermal properties. One material will melt at a different temperature than the other, for example. When that complication is added to the already difficult problem of controlling the process window for IR laser welding, the task of welding dissimilar metals is almost impossible. The result is a weld with intermetallics—variations of structure and composition that lead to inconstant mechanical strength and electrical conductivity.

The wide process window of blue laser welding makes that problem much more tractable. Early results using the AO-500 tool to weld copper to aluminum or copper to stainless steel, for example, demonstrate the same qualitative and quantitative advantages as blue light demonstrates for copper alone. That is, high-power blue lasers produce high-quality welds at increased speed.

In addition to welding, initial results show that blue lasers also have advantages for additive manufacturing. Whether for powder-bed laser sintering or laser metal deposition, improved absorption in the blue leads to improved performance. Depending on the materials, this can be as much as a 3–10X fabrication speed improvement.

Blue taking off

Users of the 150 W laser tool have already demonstrated improved welding performance for battery fabrication and other consumer electronics applications, as earlier described. Laboratory tests with a 700 W model have demonstrated the same qualitative features at processing speeds several times as fast. It is logical to expect that the fundamental physical characteristics of blue light will lead to additional applications.

REFERENCE

1. M. Silva Sa et al., Proc. SPIE, 10514, 1051407 (Feb. 19, 2018); doi:10.1117/12.2291716.

Jean-Michel Pelaprat is cofounder and chief marketing officer, Matthew Finuf is application manager, Robert Fritz is application engineer, and Mark Zediker is chief executive officer, all at NUBURU, Centennial, CO; e-mail: [email protected]; www.nuburu.net.