As the need for more compact, lightweight, covert imaging methods expands for airborne and other portable platforms, single-photon-based time-of-flight (TOF) or light detection and ranging (lidar) imaging systems are gaining in popularity because their high sensitivity allows the use of smaller, lower-power laser systems. Rather than using several-tens-of-milliwatt visible laser sources, silicon single-photon avalanche diode (SPAD) detectors, and pixel-by-pixel readout (pixel-wise) image-processing algorithms, researchers from Leonardo MW and Heriot-Watt University (both in Edinburgh, Scotland) have instead developed a single-photon imaging lidar system that improves on an earlier single-pixel design and uses a 10 mW eye-safe 1550 nm laser, indium gallium arsenide/indium phosphide (InGaAs/InP) SPAD detector, and algorithms specially designed for time-correlated single-photon counting (TCSPC) to image at ranges up to 10.5 km.

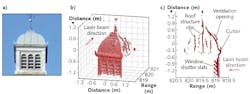

Using a class 1, 10 mW, 1550 nm erbium-doped laser with 800 ps pulses at a 125 kHz repetition rate, a SPAD detector with 25 μm active area and 100 ps timing jitter, and galvanometer mirrors to scan the optical field and direct both outgoing optical pulses and returned photons, objects were viewed through a 21-cm-diameter reflective telescope system and converted to 3D TOF images. For example, a clock tower was scanned from a range of 800 m over a 20 min. total acquisition time (170 ms/pixel), revealing depth information that includes the shape of the roof and gutter, and even allowing an estimate of the angle of the ventilation slats in a window shutter from an 85 × 85 pixel (with 2.2 cm inter-pixel spacing) image. Reference: A. M. Pawlikowska et al., Opt. Express, 25, 10, 11919–11931 (2017).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.