Novel Optical Fiber Applications: Hollow glass fiber for CO2 laser surgery has coincident aiming beam

TEODOR TICHINDELEAN

The carbon dioxide (CO2) laser, which produces a beam of infrared (IR) light at 10.6 μm wavelength, is in use extensively today as an incision tool in numerous medical procedures such as otorhinolaryngology, ophthalmology, gynecology, dermatology, plastic surgery, and general surgery.

Perhaps best known for its uses in cosmetic and dermatological treatments, CO2 lasers emit light that is absorbed by water present in a patient's skin or tissue. This creates a narrow layer of thermal necrosis sufficient to seal dermal blood vessels, yet thin enough to reduce potential scarring. Laser treatments have proven highly effective when compared with mechanical abrasion or chemical agents in laser resurfacing and other dermal procedures.

Laser devices serve an array of other clinical conditions. In areas of general medicine, surgeons may use a range of laser wavelengths and delivery systems to cut, vaporize, and remove tissue in traditional open operations and laparoscopic surgeries, including the removal of tumors or polyps, kidney stones, or prostate tissue.

Surgery via CO2 laser, often referred to as "bloodless surgery," allows a surgeon to focus on a small area, offering more comfort to patients by reducing intraoperative bleeding and postoperative pain and discomfort, facilitating the process of postsurgical wound healing. The laser seals lymphatics and blood vessels and can reduce intraoperative bleeding and the occurrence of postoperative swelling. The penetration depth of only 0.03 mm and the sealing of nerve endings as it cuts results in less edema and pain, leading to a more comfortable postoperative recovery and reduced risk of infection.

For optimal clinical outcomes, laser surgery requires trained and skilled medical professionals. For the clinician, CO2 laser surgery benefits include improved visibility of the surgical field, accuracy and control, and reduction of procedure time. The diameter and the power of the beam can be adjusted for rapid removal of large tissue amounts or removal of only a few layers. The laser beam seals capillaries and small blood vessels as it cuts the tissue. This dramatically reduces bleeding, resulting in a much drier and clearer surgical site. The boundaries between the ablated tissues and the surrounding intact tissue are very clearly defined. A CO2 laser can evaporate through the surrounding tissue without physical force, thereby sealing vessels and minimizing bleeding; thus, it is useful when a bloodless view is required during surgery. Moreover, wounds can be treated in a sterile manner because of high-temperature evaporation of tissue lesions.

Laser therapy techniques vary based on the specific procedure being performed. From both a design and clinical perspective, the laser power density directly impacts the interaction between the laser and human tissue. In general, the highest power density that a surgeon can comfortably control will yield the best results in therapeutic medical treatments and surgeries. This minimizes the duration of exposure to conductive heating produced by the laser beam, which reduces the potential for injury or damage to surrounding tissue. Additionally, each laser wavelength has a characteristic and unique effect on human tissue. The surgeon must possess not only full knowledge of the medical procedure being performed, but also the proper assembly, skills and practice in the handling and use of the selected laser technology systems.

Fiber delivery

It is important for medical clinicians and medical device designers to adequately understand the capabilities that a particular CO2 laser delivery system allows. Articulated-arm lasers are an older technology. Light delivery by fiber is a current technology offering a replacement for high cost, heavy, rigid articulated arms. Direct fiber systems may include bare fibers for holmium lasers and hollow waveguides for CO2 lasers.

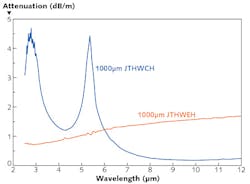

Instead of delivering the CO2 laser beam in the articulated arms embedded with mirrors or lenses, a hollow waveguide offers a viable and versatile option to deliver CO2 laser for medical laser applications. Hollow fiber is strong and flexible, and offers the ability to easily change cutting geometry in order to accommodate customization. Because typical silica-based fibers heavily absorb light with wavelengths longer than 2.1 μm, a different technology is required for CO2 laser light delivery. The IR-transmitting hollow silica waveguide (HSW) is an excellent alternative to solid-core fibers in high-power laser delivery applications. Among key benefits, HSWs can offer high laser power thresholds, low insertion loss, no end reflection, and precision accuracy.

Designed to deliver CO2 laser power in a flexible and rugged package, a hollow-fiber system designed by Polymicro Technologies, called the MediSpec HSW, consists of a fused silica capillary tube with an optically reflective internal silver/silver iodide (Ag/AgI) coating. For protection and to improve the strength and flexibility of the waveguide, the capillary tube is coated with an external protective polymer buffer layer. The internal dielectric layer is optimized for low optical power loss operation at a 10.6 μm wavelength.Because of the hollow structure, reasonable care should be taken to avoid any contamination entering the bore of the waveguide during termination and handling. The contaminant will act as a scattering point for the transmitted laser power, which might lead to internal burning. Also, particles traveling inside the waveguide bore have the potential to physically scratch the inside of the capillary silica surface, leading to dramatically increased fragility.

The coupling of power into the HSW is heavily dependent on the input beam characteristics. When coupling light into the fiber, care should be taken to avoid irradiating the glass itself with light; the goal is to minimize the input numerical aperture while keeping the spot size smaller than the waveguide bore diameter. A good rule of thumb is to target a focused beam diameter at the entry to the waveguide at approximately 70% of the waveguide bore size. When reasonably centered, this avoids the beam hitting the front edge of the waveguide and produces the best transmission characteristics.

Visible aiming beam

Excellent laser guiding and precise visible aiming beam alignment are critical requirements for handheld probes and other laser therapy equipment in the operating room. The specialty HSW waveguide designed specifically for medical laser applications integrates mid-IR laser power delivery and visible aiming beam alignment. As opposed to conventional handheld probes that carry two fiber cables, one for illumination and one for laser power delivery, the combined beam delivery system is less bulky and, importantly, decreases the chance of surgical laser burns due to lack of precision.

The HSW is designed for a range of mid- to far-IR applications; the spectral-transmission range of 2.9 to 10.6 μm allows use with erbium-doped YAG (Er:YAG) lasers as well as CO2 lasers. The fiber is fabricated in 500, 750, and 1000 μm inner diameters. The Tefzel jacket material is biocompatible and can withstand sterilization for invasive medical procedures. The fiber meets all labeling, packaging, and sterilization requirements within FDA 21 CFR 820 Quality System Regulation and cGMP.

ACKNOWLEDGEMENT

Polymicro Technologies and MediSpec are trademarks of Molex.

REFERENCES

1. H.-S. Oh and J.-S. Kim, "Clinical application of CO2 laser," CO2 Laser - Optimisation and Application, 357–378 (Mar. 21, 2012).

2. J. Clarkin, J. Shannon, and R. Timmerman, "Working with hollow silica waveguides," Polymicro Book of Technologies (Aug. 30, 2006).

3. See http://bit.ly/1KqsgRB.

Teodor Tichindelean is global product manager at Molex, Lisle, IL; e-mail: [email protected]; www.molex.com.