The Thirty Meter Telescope (TMT) under construction near the summit of Mauna Kea in Hawaii is a true monster of a telescope. The forbidding task of designing, fabricating and assembling, and operating such a telescope in a diffraction-limited manner (using adaptive optics, of course) is being undertaken because, with a spatial resolution of more than 12 times that of the Hubble Space Telescope (and a much greater light-collecting ability), the TMT will allow us to look much farther back into the early stages of the formation of the universe; examine exoplanets, their atmospheres, and their spectroscopic signatures in much greater detail; better understand black holes; and further our knowledge of cosmological physics.

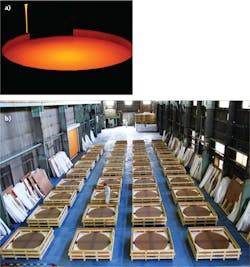

At the heart of the TMT are the 492 hexagonal mirrors that make up the telescope's primary mirror. Ohara Inc. (Tokyo, Japan) is supplying the 574 M1 segment mirror blanks needed for the telescope (including spares) and has produced more than 100 mirror blanks already. Made of Ohara's CLEARCERAM-Z HS ultra-low expansion glass ceramic, each blank is 1.5 m in diameter and about 50 mm thick, according to Brion Hoffman, president of Ohara Corp. (Rancho Santa Margarita, CA). The blanks will potentially be polished by vendors in the U.S., Japan, China, and India into the 1.4 m hexagons that will fit closely together to form the TMT's primary.

A decade's work so far

In early 2005, representatives from Ohara met with the TMT's team of scientists, astronomers, and optical engineers in a small house near Caltech in Pasadena, CA, says Hoffman. In 2006, Ohara formed a TMT task team consisting of eight core members and more than 20 support personnel from five different departments. "Ohara began a systematic approach to meeting all of the specifications listed in the 28-page TMT document, which included the tightest and most demanding coefficient of thermal expansion (CTE) specifications we ever received," he notes. "For more than eight years, Ohara worked very closely with the TMT technical team and their project partners to verify that Ohara CLEARCERAM-Z ultra-low expansion glass would be a suitable material for use in the primary mirror blanks."

To meet the stringent TMT specifications and to have the capacity required to produce the 574 primary mirror blanks, Ohara had to make significant investments in capital equipment and modify its manufacturing processes. "This included the building of a new 2000 liter melting tank, installing nine huge annealing ovens, and making improvements to our forming and ceraming processes," says Hoffman. CLEARCERAM-Z is a glass-ceramic material produced by Ohara Inc. The basic composition of the mother glass is silicon dioxide, aluminum oxide, and lithium oxide (SiO2-Al2O3-Li2O) and also includes oxides of magnesium, zinc, calcium, barium, titanium, and zirconium (MgO, ZnO, CaO, BaO, TiO2, and ZrO2). Crystals are grown isotropically in the glass by heating the mother glass, resulting in a glass matrix (20–30%) and crystals of beta-quartz solid-solution ceramic (70–80%, with a grain size of less than 100 nm). The result is a stable optical material with close to zero CTE.

"Regular" CLEARCERAM-Z has a CTE of 0.0 ±1.0 × 10-7/°C, while the CLEARCERAM-Z HS used in the TMT has a CTE of 0.0 ±0.2 × 10-7/°C. Numerous other, tighter constraints were placed on the material for the TMT blanks: in just one example, the lateral variation in CTE within each blank had to be within the range of ±15 × 10-9/°C relative to the blank operation-temperature CTE (essentially the average CTE) of the given blank.

Hoffman adds that Ohara is also the supplier of the E6 low-expansion glass that is used in the 8.4-m-diameter spin-cast mirrors produced by the Richard F. Caris Mirror Lab at the University of Arizona (Tucson, AZ). "Seven of these huge mirrors will be used in the Giant Magellan Telescope (GMT), which is also one of the world's largest and most ambitious telescope projects," he says.

First light for the Thirty Meter Telescope and for the Giant Magellan Telescope is projected for 2023 and 2025, respectively.