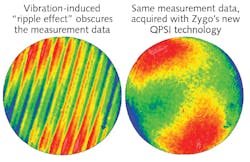

In unstable environments, phase-shifting interferometry is prone to inaccuracies because of ripple effects in the data caused when the reference optic and the optic under test vibrate out of phase. This obscures the integrity of the height map of an optical surface being tested and prolongs, for example, convergence of the polishing and other processes that rely on accurate interferometric data.

While the obvious solution is to perform interferometric testing in a stable environment, engineers at Zygo (Middlefield, CT), an Ametek (Berwyn, PA) company, have developed a phase-shifting interferometric solution called QPSI that combines patented acquisition algorithms with an optimized hardware platform. The true on-axis configuration of the measurement during acquisition inherently enables high-accuracy metrology by reducing ripple in cavities with vibration amplitudes up to 70 nm—a level of vibration beyond the capabilities of typical mechanical phase-shifting acquisition that requires near-stable environmental conditions. QPSI’s performance is a simple alternative to dynamic acquisition techniques that are often limited to accuracies in the tens of nanometers due to sensitivities to off-axis and polarization-induced error sources. This vibration-tolerant ripple reduction is available on Zygo’s Verifire QPZ and DynaFiz laser interferometer products. Reference: www.zygo.com/?/met/interferometers/qpsi.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.