VENKAT NANDIVADA

Optical-grade epoxies, silicones, and ultraviolet (UV)-curable compounds offer engineers great versatility for bonding, sealing, coating, and encapsulation applications. These systems adhere well to diverse substrates, and offer excellent temperature resistance, stress relief, and protection from moisture and other corrosive elements. These materials play an integral role not only in conventional fiber optics and optoelectronics systems, but also in various specialty medical, military, and aerospace devices.

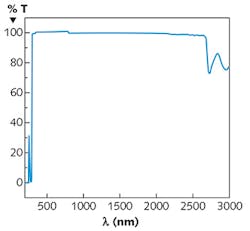

Manufacturers can find both optically clear and optically opaque polymer systems that can tightly bond optical components built from materials that include polycarbonate, acrylic, quartz, glass, and fused silica. While opaque adhesives prevent any optical leakage, clear adhesives exhibit very flat transmission curves across a wide spectrum, providing an optically clear medium with a spectral transmission that extends from UV wavelengths as low as 250 nm through visible and infrared wavelengths of 2500 nm or even higher (see Fig. 1).Optical transmission efficiency

Their transparency at the wavelengths used in fiber optics earned these compounds an early and vital role in these applications (see image at top of this page). Besides their ability to provide structural bonding of fibers, optically clear adhesives provide the natural solution for bonding fibers to connectors during manufacturing and for splices.

For splices, terminations, and transparent bonds, a polymer's refractive index and transmission characteristics are critical for ensuring maximum efficiency of optical transmission. In optical applications, any difference in refractive index at the interface between fibers or other substrates results in Fresnel reflection loss, in which some fraction of the optical signal is reflected back to the source. To meet each application's specific requirements, engineers can find an available optical adhesive with a refractive index ranging anywhere from below 1.45 to above 1.60. At best, Fresnel loss reduces the quality of the application; at worst, it can result in failures in applications such as high-energy optical systems or fiber systems using complex modulation-signaling schemes.

Critical performance characteristics

A high-transmission efficiency and well-matched refractive index are paramount for optical communications. Nevertheless, other attributes of advanced compounds can arise as more critical characteristics in other optical systems in optoelectronics, medical, military, and aerospace applications. For example, a precision optics assembly requires an optically transparent bonding system that allows sufficient time for precise alignment of components during assembly and maintains that alignment during and after the cure process. An adhesive that flows too freely can create difficulty in maintaining alignment during assembly and cure; one that shrinks during cure can disrupt alignment; and an adhesive with mechanical or thermal characteristics poorly matched to the application can gradually introduce misalignment over the lifetime of the end assembly.

To balance these types of specific assembly requirements with optical performance needs, engineers can find optical compounds such as two-part epoxies that provide a wide range of handling time, curing time, and curing temperature. Furthermore, adhesive systems such as UV-curing materials cure via simple exposure of light of the required wavelength. In fact, so-called dual-cure compounds cure on exposure to UV and to heat, simplifying manufacture of assemblies where UV illumination would be unable to reach concealed areas within complex geometries.

For many optical applications, there are other characteristics of these adhesives that play a critical role in overall quality, performance, and reliability of the end assembly. For example, the stress-reduction properties of adhesives are vital in many optoelectronic applications. Here, stress can arise at the bonded interface because of differences in the coefficient of thermal expansion (CTE) of the printed-circuit board (PCB) and bonded component. Over time, temperature variations can induce stress, separation, and eventual failure of the bond if large differences in CTE exist between the bonding material, the PCB, and the component.

Polymer systems are engineered such that they can address these concerns across a wide range of CTE requirements. Furthermore, the use of additives such as aluminum oxide or negative-CTE fillers such as zirconium tungstate can help achieve low to ultralow levels of CTEs. On the other hand, engineers can choose an optically clear silicone for applications requiring a flexible compound. As the technology of formulations has advanced, even one-part silicone systems are now available to meet NASA's low outgassing requirements.

Additional properties of adhesives come into play in certain optical and optoelectronic applications that involve rigorous temperature and humidity testing such as 85°C/85% humidity endurance tests. Adhesives and coatings that can handle these conditions can significantly augment the overall stability of the device. Please note that these compounds are equally robust in fiber-optic bundling, optical replications, potting, sealing, and LED-encapsulation-type applications.

Meeting specialized requirements

Beyond more-familiar applications in fiber optics and optoelectronics, optical adhesives have emerged as a favored solution for addressing specialized requirements in more-demanding application areas such as medical, military, and aerospace systems. For example, optical medical devices require toxin-free transparent adhesives that bond tightly to a variety of surfaces while remaining immune to radiation, chemical, sterilization, and biological agents. Medical applications also present unique requirements for safe and reliable curing methods. Where temperature limitations or concerns about UV light are a concern, highly specialized LED-cure adhesives provide a hazard-free curing approach. For example, the Master Bond LED403Med cures on exposure to 405-nm-wavelength light produced by a simple LED source and conforms to United States Pharmacopeia (USP) Class VI and ISO 10993-5 cytotoxicity requirements.

Military/aerospace applications impose additional unique requirements, combining the need for optical transparency with the ability to withstand exposure to harsh environmental conditions and extreme mechanical stress (see Fig. 2). For these high-stress applications, adhesives provide a degree of hardness and resistance to stress that is vital for systems exposed to sudden acceleration, vibration, and mechanical shock. In these cases, each adhesive's characteristic Young's modulus (also known as its elastic modulus) reflects its ability to respond to mechanical stress.An adhesive with a low Young's modulus can reduce stress caused by mechanical shock or induced by thermal expansion. In contrast, an adhesive with a higher Young's modulus will remain more rigid despite externally applied stresses. Advanced adhesive technologies allow engineers to find a specific system with a Young's modulus needed to achieve a balance between compliant stress relief and rigid dimensional stability.

For space-based optical systems, adhesives face even more extensive requirements. Along with the ability to withstand severe vibration during launch, optical adhesives need to remain immune to continued thermal shock and the vacuum of space itself. In fact, optical adhesives such as Master Bond Polymer System EP29LPSP withstand cryogenic shocks as extreme as a rapid plunge from room temperature down to liquid helium temperature (−269°C).

Optical adhesives also resist the effects of exposure to vacuum, whether in space or Earth-bound vacuum chambers. Placed in a vacuum, materials can begin to outgas any volatile constituents, possibly resulting in shrinkage of the material itself and accompanying condensation of the outgassed compounds on optics and other sensitive surfaces. Optical epoxy systems such as EP29LPSP have very low outgassing characteristics, confirmed through the NASA low outgassing test (ASTM E595).

Because of their very nature, optical systems present unique assembly challenges, further complicated by specialized application needs and environmental factors. Optical adhesives offer manufacturers the ability to meet these varied challenges with a broad array of options, easily addressing specialized applications requirements for optical clarity, bonding strength, and protective capabilities.

Venkat Nandivada is manager, technical support at Master Bond, Hackensack, NJ; e-mail: [email protected]; www.masterbond.com.