Vibration Control: Piezoelectric bimorph beams consolidate vibration control functions

TORSTEN BARTEL

Modern electronic and optoelectronic equipment and systems demand lightweight construction, high throughput, and increased production analysis and manufacturing precision. The effects of vibration, which can influence the function or even cause damage to delicate machinery and components, must be carefully considered during the research, development, and production phase. Vibration analysis and control technologies must operate on the nanometer or sub-nanometer scale; for example, the semiconductor industry demands a low-vibration manufacturing and test environment.

Because conventional passive vibration isolation methods (such as a simple spring and damping element) do not comply with these demands, active vibration isolation systems (with electronic feedback circuits to rapidly extinguish vibrations) are becoming more prevalent. In addition to considering the right installation site with adequate temperature and humidity control as well as a strong foundation for stability, researchers and engineers also need to create a low-vibration environment to ensure proper function of sensitive equipment in numerous application areas.

Low-frequency piezoelectric vibration isolation

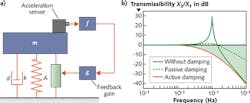

For adequate vibration isolation, the mechanical path between the source of a disturbance and the structure to be isolated must be designed in such a way that a vibration reduction is yielded in a certain frequency range. This can be achieved by adding a stiffness element k, a damping element d and, if required, an actuator element A to create a vibration isolation system (see Fig. 1).

Regarding the transmissibility of a passive isolation system between a disturbance and a vibration-isolated component, a typical amplitude response is observed. For example, an undamped isolator affects an increasing vibration isolation of -40 dB per decade in the frequency range above the resonance of a mass-spring system. However, the drawback is vibration amplification around the resonance frequency. And although this amplification can be reduced by the integration of a vibration-damping element, this damper also reduces the isolation effect at higher frequencies.

Beyond passive isolation, active vibration isolation unites the advantages of damped and undamped systems. With broadband isolation remaining at frequencies above resonance, the vibration amplification in the resonance can be reduced to an amount that is equal to the effect of a damping element.1 To do this, there are various control strategies that can be used, such as differential displacement feedback loops or model-based controls.

Most active vibration systems are based on a purely mechanical structure with independently built-up actuators and sensors. But the integration of structural, actuator, and sensor properties in one multifunctional element—like piezoelectric ceramics—offer a reduction of complexity and enable more compact designs.2

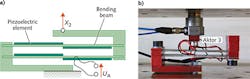

Piezoelectric bending beams, also called bimorphs, are essentially a cantilever with two (or more) active layers; typically, piezoelectric materials and metals. These bimorphs can fulfill the role of both actuator and sensor in active vibration isolation systems for sensitive equipment—especially for systems that demand low stiffness and low structural damping.

The overwhelming advantage of using a piezoelectric bimorph is its simple design. A dual-sided clamped bimorph device consists of a bending beam with mutually applied piezoelectric modules (see Fig. 2). Application of an electrical voltage provokes a bending moment by the piezoelectric modules, causing a deflection of the free end of the device. By using a parallel motion, any angular displacement of the connection points is almost avoided, and the corresponding hardware configuration can be simple, compact, and cost-effective.Three- and six-axis isolation platforms

A platform for the active isolation of sensitive equipment has to comply with requirements on isolation performance, the mass to be isolated, and the frequency range of interest. The setup of such a platform consisting of piezoelectric bimorph actuators creates new demands on the development process.

Critical to the design process is an understanding of the interdependency between the stiffness of the mount and the actuation force, as well as its frequency-dependent structural behavior. Therefore, the realization of the mount specifications must follow certain steps, starting from the optimization of an analytical model over the verification of its properties by a finite element simulation up to the experimental validation of manufactured hardware.

Supported by a flexible numerical system simulation environment, requirement specifications can be observed at any stage during the design process. The numerical model can be updated by analytical, numerical, and experimental data simply by a drag-and-drop exchange of single-system components.

Besides other parameters, velocity spectra (the speed and direction of vibration) are an important input to a methodical vibration isolation development process. Typical velocity amplitude spectra of different environments, such as offices or workshops, and recommended velocity amplitude spectra for sensitive equipment are given in certain guidelines based on the working precision of the sensitive equipment and its structural dynamics.3

On one hand, the velocities to be achieved define the design criterion for the sensors used, since they have to capture the measured velocity with a tolerable signal-to-noise ratio. On the other hand, the occurring velocities (in a laboratory facility) set the design demands on the actuator, since it has to be capable of generating the required forces for a reduction of these velocity amplitudes.

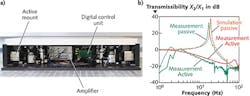

The experimental setup of an exemplary integrated vibration isolation system includes a top plate supported by four piezoelectric mounts (see Fig. 3). Each mount consists of two piezoelectric bending beams. Four acceleration sensors are collocated above each mount. Beside these functional components, static load compensation, stroke limiters, four miniaturized piezoelectric amplifiers, and the digital controller are integrated into the system. Also, all necessary power supplies are included.For an experimental evaluation, the platform is placed on a vibrating table and its transmissibility curve is measured in the passive and active case. Together with the mounted mass, the stiffness of the platform causes a first resonance frequency of 18 Hz. Already in the passive case, the measured transmission curve lies under the 0 dB line for frequencies higher than 25 Hz, therefore offering passive isolation in this frequency range.

The common drawback of the arising resonance amplitude at 18 Hz can be compensated actively. Due to the active damping effect, the frequency range of isolation can be reduced down to 2 Hz and an isolation of 18 dB in the resonance frequency can be achieved. The experimental results also prove the accuracy of the numerical prediction (see Fig. 3).

These numerical results for the active vibration isolation system show the quality of a preliminary prediction of the expected passive and active behavior. In both cases, it can be observed that the isolation performance is limited by elastic modes of the mounts and the top plate, which can be altered for more effective control to further improve the system.

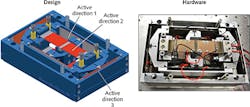

Using the same active principle, a mounting unit with three active directions is easily designed and manufactured (see Fig. 4). In this design, three parallel motions of piezoelectric bending beams are orthogonally connected in series. Each mount is able to generate—in every direction—a blocking force of 2 N and a free stroke of 40 μm, and possesses a resonance frequency of 12 Hz with a mass of 20 kg per mount. By using multiple multiaxial mounts, all six degrees of freedom of a mounted structure can be controlled.REFERENCES

1. A. Preumont, Vibration Control of Active Structures: An Introduction, Kluwer Academic Publishers (now merged with Springer-Verlag), Heidelberg, Germany (2002).

2. J. Bös et al., J. Acoust. Soc. Am., 123, 3873 (2008); http://dx.doi.org/10.1121/1.2935763.

3. C. G. Gordon, "Generic Criteria for Vibration-Sensitive Equipment," Proc. SPIE, 1619, Vibration Control in Microelectronics, Optics, and Metrology, San Jose, CA (Nov. 1, 1991).

Torsten Bartel is a researcher at the Fraunhofer Institute for Structural Durability and System Reliability (Fraunhofer LBF), Bartningstrasse 47, 64289 Darmstadt, Germany; e-mail: [email protected]; www.lbf.fraunhofer.de.