High-speed Imaging: Lissajous scanning trajectory enables video-frame-rate microscopy

Purdue University (West Lafayette, IN) scientists have reported an approximate fiftyfold increase in frame rates into the kilohertz regime for beam-scanning microscopy applications by scanning a laser over the field of view in a circuitous Lissajous trajectory similar to the repeating patterns from the children’s toy known as a SpiroGraph.1 Essentially, the galvanometer-driven mirror in a conventional galvo-resonant mirror scan head was replaced with a second resonant mirror that enabled Lissajous scanning.

Image reconstruction

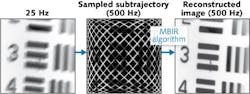

To achieve high frame rates, the full Lissajous trajectory was divided into subtrajectories, each of which sparsely but rapidly sampled the field of view. A spatiotemporal model-based image reconstruction (MBIR) 3D inpainting algorithm, which populates the unsampled pixels in a given subtrajectory based on a maximum a posteriori estimation of the data in both time and space, was developed to reconstruct the images using the full information content of the data stack. High-quality images (256 x 256 pixels) were recovered from frames in which ~30% of the pixels were directly interrogated, resulting in 500 Hz imaging. Because the detectors were simple photodiodes or photomultiplier tubes, multiple imaging modalities were simultaneously acquired at kilohertz frame rates.

In the study, the authors focused on two key effects commonly necessitating high-speed imaging: namely, motion blur and transient events. Blur resulting from rapid sample translation (due to sample vibration from, for example, breathing or a heart beating) was reduced by choosing subtrajectories, resulting in frame rates of 100 Hz and 1.25 kHz. Increasing the frame rate to beyond 100 Hz successfully eliminated obvious effects from sample blur, as observed with 25 Hz Lissajous imaging and 15 Hz conventional raster scanning (see figure).

Transient changes in intensity within a fixed field of view (such as in action-potential imaging, vesicle budding, and crystal nucleation) were modeled by performing rapid-polarization-modulation imaging of urea crystals. By rapidly changing the polarization of the incident beam and detecting the separated horizontal and vertical components, an integrated intensity of the various crystalline domains is observed. However, increasing the frame rate to 1.46 kHz captures the evolution of intensity as a function of time as the incident polarization is rapidly modulated. There is some inevitable trade-off; as the sampling becomes too sparse at too high of a frame rate (around 10% sampling per subtrajectory), the quality of the recovered images is reduced.

Several other groups have realized Lissajous trajectory imaging by resonantly scanning fibers or by using microelectromechanical mirrors, but with frame rates significantly less than video rate.2,3 The major differences in the present study are twofold: (1) the authors used phase-stabilized mirrors with high quality factors and high (tens of kilohertz) frequencies coupled with high-speed data-acquisition electronics, and (2) the MBIR algorithm enabled recovery of quality images using a paucity of sampled pixels in any one frame.

“A key advantage of the method is its experimental simplicity,” says Purdue University professor Garth J. Simpson. “The increase in frame rate on multiple parallel acquisition channels requires only the addition of one or two resonant mirrors to the beam path of a standard confocal or multiphoton microscope.”

REFERENCE

1. S. Z. Sullivan et al., Opt. Express 22, 20, 24224–24234 (October 6, 2014).

2. Schnitzer et al., Nat. Meth. 2, 12, 941–950 (2005).

3. Ben-Yaker et al., J. Appl. Opt. 50, 16, 2376–2382 (2011).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.