Photonics Products: Visible Laser Diodes: Laser diodes (almost) encompass the entire visible spectrum

The laser diode (LD) is by far the most common type of laser in the world, with millions being used in fiber-optic communications and mass-market applications. Laser diodes that operate in the visible spectrum (usually stated to be 400 to 700 nm, although the human eye can see near-IR out to 780 nm, and further at high-enough intensities) can be found in such common items as computer mice, CD/DVD/Blu-Ray reading and recording devices, and low-end pointers. Visible LDs also serve as high-end sources for scientific, forensic, and other applications.

Red-emitting LDs were the first to come into general use, appearing widely in the 1980s in, for example, CD players. Today's red-emitting LDs are typically aluminum gallium indium phosphide (AlGaInP)-based and are available at wavelengths from the edge of the visible to as short as the 633 nm helium-neon (HeNe) laser line.

Gallium aluminum nitride (GaN)-based LDs, which appeared on the market at around the turn of the century, greatly expanded the array of colors that LDs could produce. These LDs can be made to emit at wavelengths ranging from the UV to longer than 500 nm; today's laser user can buy visible GaN-based LDs that emit in the violet, blue, or green. It should be noted that, due to the lack of suitable semiconductor structures thus far, no commercial yellow- or orange-emitting LDs exist.

Visible LDs, which are often hermetically sealed in a small windowed can, or combined into multi-emitter bars, can be purchased in many configurations: the bare LD or bar; the LD in a can; an LD plus a single-mode or multimode fiber pigtail; as a laser module, forming a rugged component that can be, for example, wavelength stabilized; or as part of an entire photonic system. Because a standard edge-emitting LD produces a diverging beam with an elliptical cone, collimating optics that expand the beam differently in orthogonal directions are often required.

The number of visible LD products and applications is vast; accordingly, this article can only present a sampling of the ever-widening selection of these devices on the market.

Red, green, and blue together

One of the most obvious advantages of having LDs that emit in the red, green, and blue (RGB) is that these lasers can be used together to create light that appears to be any color to the human eye, including white, enabling compact, high-color-gamut laser projectors.

Power Technology (Little Rock, AR) produces LDs and LD modules with wavelengths ranging from the UV to the IR, including the newest LD wavelength to be developed and commercially produced—green. The company's highest-power visible LD is a 1.6 W multimode blue device available with wavelengths in the 435 to 455 nm range; close behind in power is a 1.5 W red emitter available in the 663 to 677 nm range (The company makes lower-power single-mode visible LDs as well). Its longest-wavelength green LD emits 50 mW at 520 nm and is single-mode.

The company's LD modules, which all contain optics that produce a round, collimated beam, come in different varieties, including temperature stabilized, low speckle, and long-coherence length (30 m). The low-speckle version contains a moving diffuser that can reduce speckle to a 2 to 3% contrast over 1 to 10 ms, a property suitable for interferometry, lithography, projection, and other uses.

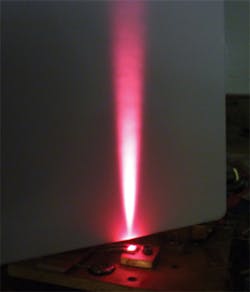

As for laser projection, Power Technology is quite involved: at SPIE Photonics West 2014 (San Francisco, CA; Feb. 1 to 6), the company unveiled its iLLUMINA projection laser, which contains red, green, and blue laser sources specifically chosen to provide a wide color gamut, according to Walter Burgess, VP of sales and engineering at Power Technology (see Fig. 1). "The source is in part based on semiconductor lasers," notes Burgess. "Specifically, GaN-based LDs produce the blue component of the spectrum, while the red component is covered by AlGaInP-based LDs."

Current versions of the projector are aimed at smaller screen sizes; larger screens will soon be handled by the next generation of iLLUMINA projectors, says Burgess. Advantages over xenon-lamp projectors include brighter screens with better color gamut, lower operating and maintenance costs, and safer operating conditions (xenon bulbs produce UV rays that are a hazard and reach temperatures of greater than 1000°C).

Fiber-coupled high power

Known for its high-power LDs and LD bars, Dilas Diode Laser (Tucson, AZ) produces blue- and red-emitting LDs in a variety of types. These include red (635 to 689 nm) LDs in the form of single emitters and bars, as well as in fiber-coupled packages with fiber-core diameters from 100 μm on up, according to Steve Patterson, the company's VP and GM. Applications of these red lasers include cinema projection, photodynamic therapy, and pumping of solid-state and alkali-vapor lasers.

"In the red, the well-established tailored bar (T-Bar) concept developed at Dilas is employed," says Patterson. "Modules with 50 W of polarized light at 638 nm coupled into a 400 μm fiber with a numerical aperture (NA) of 0.22 have been produced. Polarization combining can be used to further scale the output power or increase the brightness and couple into a 200 μm fiber. Further increases in the output power can be accomplished by increasing the beam-parameter product (BPP) of the resulting laser source."

The company's blue LDs are fiber-coupled into core diameters of 200 to 400 μm and upward, with wavelengths from about 450 nm down to 405 nm; power levels of 10, 25, and 40 W are standard and are scalable to 200 W and higher depending upon the application.

"In the blue spectral range, single emitters are employed and coupled side-by-side to enable high fiber-coupled output power," says Patterson. "Based on this concept, 10 W and 25 W beam sources were recently introduced to the market. The modular-combining concept Dilas has developed for these packaged single emitters enables scaling of power into the hundreds of watts, depending upon fiber-core size."

Tailored output of many colors

Many scientific and industrial applications require LD light that is controlled by external electronics and/or optics to fit custom needs. Wilhelm Kaenders, president of Toptica Photonics (Munich, Germany), says, "Although we offer laser diodes on their own, our claim is that we convert 'laser diodes' to 'diode lasers'. From being an optoelectronic semiconductor subcomponent, we convert them to a laser tool, where the electronically enabled optical performance is the key to the success, adding or destroying coherence, spectral stability, wavelength agility, improving beam quality, and reaching wavelengths that are not accessible by laser diodes on their own."

Kaenders notes that Toptica uses various laser diodes from all over the world, with many coming from Toptica's sister company Eagleyard Photonics (Berlin, Germany). "We are dealing with single-spatial-mode laser diodes (ridge-waveguide Fabry-Perot type), spectrally narrowed, single frequency, or tunable (distributed-Bragg reflector and fiber Bragg-grating types)," says Kaenders. Many of them have special coatings and packaging, he adds, noting that Toptica sometimes uses semiconductor optical amplifiers to boost the output power to the multiple-watt level without loss of spatial-beam quality.

The company manufactures compact industrial and scientific "diode-laser" systems for imaging, detection, marking, scanning, and testing and inspection for industries as various as biophotonics, optical data storage, semiconductor metrology, laser cooling, seeding, and mastering. Kaenders mentions in particular the iChrome MLE, a module with multiple lasers inside, enabling three or four colors produced by LDs of wavelengths such as 405, 445, 488, 515, 640, 690, and 780 nm (see Fig. 2).The single-box iChrome device has polarization-maintaining-fiber output, automated fiber coupling for high passive and active control, individually addressable LDs, fast switching with complete on/off (zero photons in the off state), advanced calibration of power levels from micro- to milliwatts, and a dynamic power setting range greater than 103. Digital or analog laser control is available, along with active speckle and optical-feedback control and integrated spectral clean-up filtering.

Visible VCSELs and arrays

The vertical-cavity surface-emitting laser (VCSEL) shares the basic semiconductor diode form with edge-emitting LDs, but the geometry is different. A VCSEL is in essence a very thin disk laser fabricated on a wafer, with light emitted by the top surface. Commercial electrically pumped VCSELs can be made inexpensively and have a naturally round beam. VCSELs can be fabricated in arrays that emit very high powers.

Princeton Optronics (Mercerville, NJ), most familiar as a maker of IR VCSELs and arrays, including high-power arrays for illumination, also manufactures red-emitting VCSELs and arrays (see Fig. 3). These devices emit at wavelengths ranging from 650 to 690 nm and at power levels ranging from a few milliwatts to several tens of watts, according to Chuni Ghosh, the company's CEO."In particular, Princeton Optronics has developed single-VCSEL devices in the 1 to 3 mW power range and high-power red VCSEL arrays emitting 10 to 40 W of optical power at 650 and 688 nm," says Ghosh. "Such arrays are comprised of around 100 to 1000 single-VCSEL emitters, all electrically driven in parallel. The array is mounted on a high-thermal-conductivity submount. These arrays have the added advantages of higher power-conversion efficiency and lower speckle compared to other technologies."

The most common applications of these red VCSELs and arrays include medical, laser printing, bar-code scanners, and laser-based displays, notes Ghosh.

Machine vision, life sciences

Coherent Inc. (Santa Clara, CA) makes visible LD products that typically incorporate the LD chip, a cooling system, collimating lens, beam-conditioning optics, a power supply, and control electronics. The purpose of these other components is to transform the bare diode laser into a high-performance, highly repeatable laser module with good power stability, low power noise, low optical noise, and a high degree of uniformity in the output profile, whether it's a simple beam or a complex structure. The turnkey modules are optimized for applications primarily in two high growth areas: life sciences and machine vision (especially 3D inspection).

According to Wallace Latimer, Coherent's product-line manager for machine vision, Coherent supports the machine-vision market with LD-based modules ranging across the visible spectrum (and into the near-UV and near-IR as well) that have output powers from a few milliwatts up to 7 W (see Fig. 4). Configurations range from very basic line projectors for simple sizing and alignment applications to modules that produce lines with high power and uniformity. The machine-vision laser product family also includes modules that project complex patterns and beam shapes tailored to particular applications and customers.For example, the StingRay-series of products consists of a laser head (LD plus collimating, line-generating, and focusing optics) and the option of either a separate drive electronics module or drive electronics integrated into the laser head. The driver supports analog and digital modulation at speeds up to 500 kHz; the option of a separate, stand-alone driver reduces the laser head length to 52.9 mm, as opposed to 95.1 mm.

Wavelengths from 450 to 830 nm are available with output powers as high as 200 mW and output fan angles in the 1° to 75° range, notes Latimer. Pointing stability is better than 10 μrad/°C and line straightness is better than 0.1% over 25 mm; specified line intensity nonuniformity is ±5%, thanks to the use of a novel aspheric line generator that is designed specifically to be volume-manufactured. All StingRay products support "dynamic line balancing," which eliminates any intensity bias that occurs when using the laser at off-axis-illumination angles, says Latimer.

As for applications in the life sciences, some of the company's OBIS lasers incorporate LDs, most notably at 405, 488, 514, and 640 nm; these devices provide fast direct modulation, enabling imaging applications in microscopy. Miniaturization and high electrical efficiency are an advantage particularly in areas like flow cytometry, says Matthias Schulze, Coherent's director of marketing, OEM components, and instrumentation. Here, instrument builders and users often need to incorporate multiple laser wavelengths into a single instrument; in response, Coherent has introduced the OBIS Galaxy beam combiner, which enables "plug-and-play" multilaser (and thus multicolor) combination into a single-mode, single-fiber output.

The recent shift in several types of medical instrumentation from just pure research toward clinical use, and ultimately point of care, has created an even stronger emphasis on OEM laser sources that are compact and ultrareliable, says Schulze. These lasers must be very cost effective in order to overcome competition from LED-based light sources, which offer lower source price (although the total system cost for LED-based systems can actually be higher than for lasers, he notes). In response, Coherent introduced the BioRay module family at SPIE Photonics West 2014; these new modules deliver a particularly small footprint and low cost for applications in the burgeoning compact point-of-care device market.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.