LEDS: White LED comprises blue LED and inexpensive dye

In 1997, the first white light-emitting diode (LED) was fabricated using a structure based on gallium nitride (GaN) and the phosphorus cerium:yttrium aluminum garnet (Ce:YAG).1 While efficient and bright, this LED fabrication process used inorganic phosphorus materials that can be inconsistent and expensive. Alternatively, researchers from the University of Palermo (Palermo, Italy) and semiconductor foundry Novagan (Lausanne, Switzerland) have developed a simpler, less expensive method to fabricate a white-light LED using a source that acts as a pump for the photoluminescence of an organic substance—essentially, optical frequency downconversion using a perylene-based dye.2

Organic color conversion

The high-efficiency, cool-white LED light was obtained via yellow downconversion from a GaN/indium GaN (GaN/InGaN) blue LED. Rather than using a conventional inorganic color-conversion process, the blue LED was used to pump a Lumogen perylene-based dye from BASF (Charlotte, NC). The commercially available dye (or pigment) has an absorption maximum at 450 nm and a broad fluorescence peak around 500 nm.

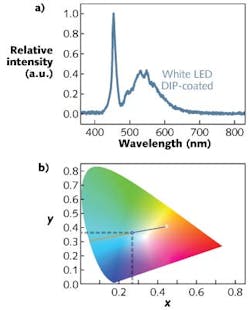

First, standard InGaN-based blue LEDs were fabricated on a sapphire substrate by metal-organic chemical vapor deposition (MOCVD). The peak emission wavelength of the LEDs was centered at 450 nm with chromatic coordinates (0.1477, 0.0338) in the CIE chromaticity diagram.

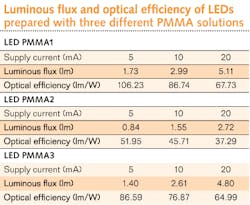

Lumogen dye was dissolved in a polymethylmethacrylate (PMMA) solution using ethyl acetate as a solvent, and different PMMA molecular weights were tested. The bare side of the sapphire substrate was coated with the dye solution by either spinning or dipping so that different coating thicknesses could be obtained. Emission spectra and chromatic coordinates were measured by a spectrometer and a calibrated photodiode with the LED being driven by a constant current (5, 10, or 20 mA).

Three solutions were prepared at different weight percentages—two at 8% (PMMA1 and PMMA2) and one at 11% (PMMA3)—in order to optimize the LED output parameters (see figure and table). Solutions PMMA1 and PMMA3 were prepared with a polymer of molecular weight 350,000, while PMMA2 used a polymer of molecular weight 996,000. Equal amounts of dye were used for each solution and the spinner velocity was 1200 rpm.Commercial-grade performance

Based on the measured parameters, the best results were obtained by dip-coating the PMMA1 solution. While the coating is scarcely homogeneous, it is significantly thicker compared to using a spin-coating method. The researchers demonstrated what they call record flux values of 9.37 lm and 118.23 lm/W of optical efficiency (with 20 mA of driving current) and a pure, intense white light with chromatic coordinates of (0.2687, 0.3629). The dye-based white LED specifications beat those of a commercially available OSRAM Opto Semiconductors (Regensburg, Germany) TOPLED long-life LUW T6SG white LED with 5–6.3 lm output and 50 lm/W efficiency.

“Fabricating a white LED using an organic material rather than a traditional phosphor lets LED manufacturers benefit from using a dye that is both cheap and easy to dispose of—consisting merely of pigments often used for graphic arts,” says the University of Palermo’s Mauro Mosca. “Given the simplicity of the operation of deposition, the process is suitable to industrial production and the high efficiency of the white-light LED at low driving current makes it a proper device for lighting solutions with low power consumption.”

REFERENCES

1. S. Nakamura and G. Fasol, The Blue Laser Diode (The Complete Story); Springer-Verlag; Heidelberg, Germany (1997).

2. F. Caruso et al., IEEE Electron. Lett., 48, 22, 1417–1419 (Oct. 25, 2012).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.