PHOTONICS APPLIED: OPTICAL DATA STORAGE: Can new techniques continue to densify optical data storage capacity?

Of the roughly $7.6 billion dollar laser market in 2012 as forecast by PennWell's Strategies Unlimited (Mountain View, CA), nearly $785 million dollars—more than 10% of the total market—was for sales of optical data storage lasers.1 Overall, however, sales of laser diodes (primarily to Japanese companies) for optical data storage markets are expected to continue their decline beyond 2012 due to falling component prices, market maturity, and consumer/business use of nonoptical flash drives and "cloud" data storage options. Since 2011, sales revenues for 780 nm compact disc (CD) and 650 nm digital video disc (DVD) laser diodes will continue to fall, while 405 nm Blu-ray disc (BD) laser diode sales should continue to increase at a moderate pace.

Despite this forecast decline in optical data-storage laser sales through 2015, new technologies such as holographic data storage, three-dimensional (3D) optical storage, and HAMR could change the market outlook significantly. Optical memory and optical data storage capacities are moving beyond the terabit-per-square-inch territory through a variety of photonic/optical recording means. These hybrid bulk-optic, laser-assisted, or near-field and super-resolution methods such as patterned media based on nanolithography will no doubt be strong players in the optical data storage networks of the future. However, certain cost and technology obstacles must be cleared before any of these next-generation platforms become commercially viable.

More storage capacity

Optical data storage capacity ramps upward as wavelength (and recording feature size) decreases: CDs store around 700 Mbytes and DVDs nearly 5 Gbytes of data. According to the Blu-ray Disc Association (www.blu-raydisc.com), one-layer BDs can store 25 Gbytes, while two-layer BDs (two optical layers on the same side of the disc) can store 50 Gbytes. And several manufacturers are now offering three- and four-layer BDXL technology that supports 100 Gbyte and 128 Gbyte storage, respectively.

And what is the archive life for optical discs? The range is very broad—from an estimated 5 to 10 years for CDs (without surface damage) up to 50 years of archival life for BDs, according to the purchase specification for the Panasonic Long Life Dual Layer 50 Gbyte Blu-ray disc.2

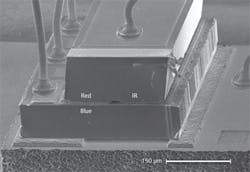

All disc-based optical storage is based on the same technology principle: A laser diode creates pits or indentations in a polymer layer or layers (typically polycarbonate) of a rotating disc (from the center outward) that are then read by the laser as ones (1s) or zeroes (0s) and interpreted as a binary data code for transmission as sound/video to your disc player. Blu-ray players are typically backward-compatible with CD and DVD players by using, for example, Sony (Tokyo, Japan) SLD6562TL stacked-die, five-pin, triple-laser-diode technology (see Fig. 1).3

In his January 2012 presentation at the IEEE ICCE conference in Las Vegas, NV, optical data storage expert Richard G. Zech, president and managing principal of The ADVENT Group (Colorado Springs, CO), sees Blu-ray and its variants as the future of optical storage.4 Holographic and 3D methods, he says, will never achieve commercial viability in the short term. Unfortunately, Zech notes that even Blu-ray has reached a theoretical data storage limit: Its 405 nm wavelength and typical 0.85 numerical aperture (using conventional objective lenses) create indentations vertically separated by spacings (called track pitch) on the order of 320 nm, limiting single-layer storage capacity to 25 Gbytes or 18.1 Gbytes per square inch.

But in the near term, Zech sees several options for expanding storage using a Blu-ray platform and its 120 mm disc, including near-field and multilayer recording. Further down the road (once technologies mature and prices decrease), ultraviolet (UV) and even x-ray discs are possibilities, along with nanolasers or very small aperture lasers and patterned media enabled by nanophotonic advances, plasmonics, and even photon sieves for far-UV and x-ray spot generation.

Beyond conventional Blu-ray

One of the most immediate and cost-effective opportunities to increase optical data storage capacity beyond Blu-ray is to use the same blue laser in a near-field configuration—essentially, using photonic "tricks" such as solid-immersion lenses and evanescent waves to overcome the diffraction limit and fixed spot size of conventional optics.

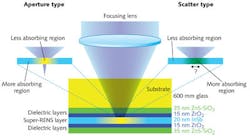

A team from Delft University of Technology (Delft, the Netherlands) and CEA-Leti (Grenoble, France) recently used near-field techniques to obtain 25% spot-size reduction (to 100 nm) through a thermally induced near-field scatterer on an indium antimonide (InSb) optical disc using a 405 nm laser source, achieving 46 Gbytes data storage in a single optical layer (see Fig. 2).5 As of yet, however, no commercial near-field techniques are available for consumer or industrial optical data storage.Another extension of Blu-ray technology is multilayer recording. One variant is the digital multilayer disk (DMD), formerly known as fluorescent multilayer storage (FMS), in which 10–50 stacked layers of the substrate contain 0.5-μm-diameter pits of fluorescent material.6 When a laser reads the substrate, fluorescent light is emitted at a different wavelength so there is no interference between the read/write beams, potentially allowing FMS to store up to a terabyte of data in 100 layers of a DVD-sized disc. And because an FMS drive could read a DVD disc, there was much hope by its developing company, Constellation 3D, for commercial introduction. Unfortunately, the technology was purchased by D-Data Inc., who also appears to be out of business.

Sony has made the most multilayer technical progress with 30-layer optical data storage using nonlinear light absorption and a picosecond laser; but again, no commercial optical data storage systems implement multilayer technology (nor will they on this scale unless component costs are dramatically reduced) beyond the four-layer BDXL.7

Of course, data storage capacity increases are possible by moving beyond Blu-ray 405 nm laser diodes to UV diodes. The smaller wavelength brings smaller spot sizes, smaller features, and higher storage capacities. However, commercially available UV laser diodes in the 350 nm region are currently priced in the $40 range (per http://ledmuseum.candlepower.us/leduv.htm)—a factor of 4–20 higher compared to the $2–$10 for 405 nm BD diodes (depending on power level) and therefore not yet cost-effective enough for commercial implementation.

Holography; but when?

At the 2012 Optical Data Storage (ODS) Workshop held in June at the University of Arizona (Tucson, AZ), Gilles Pauliat from the Laboratoire Charles Fabry de l'Institut d'Optique (Palaiseau, France) presented "High Capacity Data Storage Inspired from Lippmann Interference Photography"—an alternative to holographic methods in which the image beam carrying the data information interferes with its reflection onto a mirror, meaning no external reference beam is required.

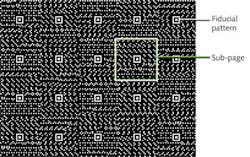

Pauliat says that most volumetric or 3D data storage techniques store bits of data in the focus of two counterpropagating beams. But page-oriented approaches have even higher storage potential, wherein data pages are imprinted on an image beam that is subsequently recorded in a volume by interfering the image beam with a reference beam, allowing multiple pages of data to be stored in the volume using angular, phase, or wavelength multiplexing options.8

In the Lippmann architecture, the incident image beam passes through the recording medium and is reflected back by a mirror. The incident and reflected beams interfere and record a complex Bragg structure in the recording material (see Fig. 3). After recording, the mirror is removed and the Bragg structure is illuminated with white light to diffract the recorded image with its original wavelength spectrum. For data storage, images at different wavelengths are usually recorded and retrieved sequentially and correspond to different sets of data (in this demonstration, two wavelengths were used: 532 and 475 nm). The Lippmann method as described is predicted to provide capacities up to a few terabytes of data per disc.In February 2012, Laser Focus World wrote about the holographic data storage techniques in volumetric crystal media developed by Access Optical Networks (AON; Monmouth Junction, NJ). "Holographic data storage has the ability to increase both density and data transfer by 1000X over the next ten years," says Glenn Gladney, president and cofounder at AON. "AON will use the proceeds from our fall 2012 completion of a $17.5 million capital launch program, in progress, to optimize MEMS-based components and long-wavelength lasers—taking advantage of commercially available telecom products—in a compact, cost-effective optical data storage solution within the next 18 months."

Despite these technology advances and commercial projections, no commercial holographic data storage options exist. Even InPhase Technologies (Longmont, CO), who announced the "First Commercial Holographic Storage Product" with its Tapestry 300R bit-storage technique (300 Gbytes of data on a 5.25 in. disc with a transfer rate of 160 Mbit/s) in a press release back in 2007, filed for Chapter 11 bankruptcy in late 2010. Fortunately, the assets of InPhase were recently purchased by hVault (http://hvault.com), and the company is planning to release a 300 Gbyte disc product, with archival storage systems that could accommodate as many as 2 to 8 drives and 540 disc slots for multiple terabytes of 50-year-lifetime data storage.

HAMR on the horizon

Although not typically categorized as an "optical data storage" method, HAMR would significantly increase the quantity of infrared laser diodes (780 or 870 nm) sold into magnetic data storage markets.

Just as Blu-ray has reached its conventional optical limit, magnetic data recording has reached its "superparamagnetic" limit; that is, magnetic grain sizes are at minimum manufacturable values of around 25 nm, limiting how easily the polarity of these grains—that encode the "1s" and "0s" to make data storage possible—can be switched. Infrared laser diodes enable the HAMR option that, in simple terms, allows "easier" switching of the magnetic state for increased data storage within existing magnetic media—essentially challenging the superparamagnetic limit just as photonic methods overcome the diffraction limit.

In March 2012, Seagate (Cupertino, CA) announced that it had reached an optical storage density of 1 Tbyte per square inch using HAMR technology. But as stated in the Seagate press release, HAMR technology "… promises to double the storage capacity of today's hard drives upon its introduction later this decade and give rise to 3.5-inch hard drives with an extraordinary capacity of up to 60 terabytes over the 10 years that follow." Not exactly an encouraging product-introduction timeline.

Of course, x-ray, nanophotonic, and atomic-level data storage is in its infancy, so I'll leave that to Jeff Hecht to discuss in a future Laser Focus World "Photonic Frontiers" article.

REFERENCES

1. T. Hausken, Strategies Unlimited, The Worldwide Market for Lasers: Market Review and Forecast 2012, Fifth edition (January 2012); http://bit.ly/NAiUJN.

2. Panasonic Long Life Dual Layer 50GB Blu-ray Disc product information; www.sell.com/2C4SN4.

3. Report, "LED: Sony Triple Wavelength Laser Diode for PS3 Blu-ray Disc Player," iMicroNews online; http://bit.ly/UhJKVf.

4. R.G. Zech, "The Future of Optical Data Storage," pres. at IEEE ICCE Conf. 2012, Las Vegas, NV (Jan. 13–16, 2012); http://slidesha.re/PEdrOT.

5. A.C. Assafrao, Opt. Exp., 20, 9, 10426–10437 (2012).

6. Lascon Storage web site, "Digital Multilayer Disk (DMD)" (2012); http://bit.ly/S5NlrP.

7. S. Tashiro et al., "Volumetric Optical Recording with Void Marks Using an All-Semiconductor Picosecond Laser," Japanese J. Appl. Phys., 50, 09MF038 (2011).

8. K. Contreras and G. Pauliat, Appl. Opt., 50, 30, 5816–5823 (2011).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.