The fiber laser is a variation on the standard solid-state laser, with the medium being a clad fiber rather than a rod, a slab, or a disk. Laser light is emitted by a dopant in the central core of the fiber, and the core structure can range from simple to fairly complex. A key factor for fiber lasers is that the fiber has a large surface-to-volume ratio so that heat can be dissipated relatively easily.

Fiber lasers are optically pumped, most commonly with laser diodes but in a few cases with other fiber lasers. The optics used in these systems are usually fiber components, with most or all of the components fiber-coupled to one another. In some cases, bulk optics are used, and sometimes an internal fiber-coupling system is combined with external bulk optics.

A diode pump source can be a single diode, an array, or many separate pump diodes, each with a fiber going into a coupler. The doped fiber has a cavity mirror on each end; in practice, these are fiber Bragg gratings, which can be fabricated within the fiber. There are no bulk optics on the end, unless the output beam goes into something other than a fiber. The fiber can be coiled, so the laser cavity can be many meters long if desired.

Dual-core structure

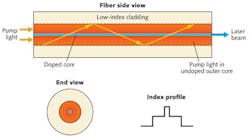

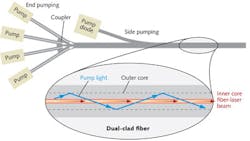

The structure of the fiber used in fiber lasers is important. The most common geometry is a dual-core structure (see Fig. 1). An undoped outer core (sometimes called an inner cladding) collects the pump light and guides it along the fiber. Stimulated emission generated in the fiber passes through the inner core, which often is singlemode. The inner core contains the dopant (ytterbium or erbium) that is stimulated to emit radiation by the pump light. Numerous noncircular variations exist on the shape of the outer core; these shapes, which include hexagonal, D-shaped, and rectangular, decrease the chances of the pump light missing the central core.

A fiber laser can be end- or side-pumped (see Fig. 2). In end-pumping, the light from one or many pump lasers is fired into the end of the fiber. In side-pumping, pump light is coupled into the side of the fiber; actually, it is fed into a coupler that couples it into the outer core. This is different from side-pumping a laser rod, where the light comes in orthogonally to the axis.Many design considerations go into making this work. Considerable attention is spent on coupling the pump light into the core, matching it to the optical absorption, and coupling that pump light into the inner core to produce a population inversion that will result in stimulated emission in the inner core. The laser core can have various degrees of gain, depending on the doping in the fiber as well as on the fiber length. These are factors that the design engineer would adjust to get the performance that is needed.

Power limitations can arise, particularly from working within a singlemode fiber. Such a fiber core has a very small cross-sectional area, and as a result, very high-intensity light going through it. Nonlinear Brillouin scattering becomes increasingly important at these high intensities, and can limit output at multikilowatt levels. If the output is high enough, the fiber end can be optically damaged.

Features of fiber lasers

Using a fiber as a laser medium gives a long interaction length, which works well for diode-pumping. This geometry results in high photon conversion efficiency, as well as a rugged and compact design. When fiber components are spliced together, there are no discrete optics to adjust or to get out of alignment.

The fiber-based laser design is highly adaptable. It can be adapted to do anything from welding heavy sheets of metal to producing femtosecond pulses. Many variations exist on the fiber-laser theme, as well as some configurations that are not, strictly speaking, fiber lasers. Fiber amplifiers provide single-pass amplification; they're used in telecommunications because they can amplify many wavelengths simultaneously. Fiber amplification is also used in the master-oscillator power-amplifier (MOPA) configuration, where the intent is to generate a higher output from a fiber laser. In some circumstances, an amplifier is used even with a continuous-wave (CW) laser.

Another example is fiber-amplified spontaneous-emission sources, in which the stimulated emission is suppressed. Yet another example is the Raman fiber laser, which relies on Raman gain that essentially Raman-shifts the wavelength. This is an application that's not in wide use, although it's certainly being used in research. In fact, some new research is going on into using fluoride glass fibers for Raman lasing and amplification rather than the standard silica fibers.

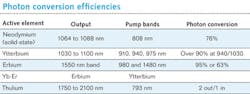

However, the fiber host is usually silica glass with a rare earth dopant in the core. The primary dopants are ytterbium and erbium. Ytterbium has center wavelengths ranging from about 1030 to 1080 nm and can emit in a broader range of wavelengths if pushed. Using pump diodes emitting in the 940 nm range can make the photon deficit very small. Ytterbium has none of the self-quenching effects that occur in neodymium at high densities, which is why neodymium is used in bulk lasers and ytterbium is used in fiber lasers (they both provide roughly the same wavelength).

Erbium fiber lasers emit at 1530 to 1620 nm, which is an eye-safe wavelength range. This can be frequency-doubled to generate light at 780 nm—a wavelength that's not available from fiber lasers in other ways. And finally, ytterbium can be added to erbium so that the ytterbium absorbs pump light and transfers that energy to erbium. Thulium is another dopant that emits even deeper into the near-infrared (NIR; 1750 to 2100 nm), and is thus another eye-safe material.

High efficiency

Fiber lasers are quasi-three-level systems. A pump photon excites a transition from a ground state to an upper level; the laser transition is a drop from the lowest part of the upper level down into some of the split ground states. This is very efficient: For example, ytterbium with a pump photon at 940 nm produces an emitted photon at 1030 nm—a quantum defect (lost energy) of only about 9% (see table).

In contrast, neodymium pumped on its standard 808 nm pump line has a quantum defect of about 24%. So ytterbium has an inherently higher efficiency, although not all that efficiency can be realized because some photons are lost. Ytterbium can be pumped in a number of bands. Erbium can be pumped at either 1480 or 980 nm; the latter is not as efficient from a photon defect point of view, but is useful even so because better pump sources are available at 980 nm.

Overall fiber-laser efficiency is the result of a two-stage process. First is the efficiency of the pump diode. Semiconductor lasers are very efficient, with on the order of 50% electrical-to-optical efficiency. Laboratory results are even better, with 70% or even more of the electrical pump energy being converted into light. When this output is matched carefully to the fiber laser's absorption line, the result is the pump efficiency.

The second is the optical-to-optical conversion efficiency. With a small photon defect, high excitation and extraction efficiency can be achieved, producing an optical-to-optical conversion efficiency on the order of 60% to 70%. The result is a wall-plug efficiency in the 25% to 35% range.

Configurations for many purposes

Continuous-wave fiber lasers can be either single- or multimode (in terms of transverse modes). A single mode produces a high-quality beam for materials working or sending a beam through the atmosphere, while multimode industrial lasers can generate higher raw power. If an application does not require the extremely high intensities resulting from singlemode operation, the higher total power from multimode operation is often an advantage—for example, for some kinds of cutting and welding, and particularly for heat-treating, where a large area is illuminated.

Long-pulse fiber lasers are essentially quasi-CW lasers, typically producing millisecond-type pulses. Typically they have a 10% duty cycle (resulting from the pump diode modulation). This results in higher peak powers than in CW operation—typically on the order of ten times higher. This can be an advantage for some kinds of materials working such as pulse drilling. The repetition rate can range up to 500 Hz, depending on the pulse duration.

Q-switching is possible in fiber lasers, with the principle being the same as for bulk Q-switched lasers. Typical pulse lengths range from low nanosecond up to the microsecond range; the longer the fiber, the more time is needed to Q-switch the output, producing a longer pulse.

Fiber properties impose some limitations on Q-switching. Nonlinearities are more severe in a fiber laser due to the core's small cross-sectional area, so the peak power has to be somewhat limited. One can either use bulk Q-switches, giving higher performance, or a fiber Q-switch, which is spliced to the ends of the active part of the fiber laser.

The Q-switched pulses can be amplified in fiber or in bulk. An example of the latter is found at the National Ignition Facility (NIF; Livermore, CA), where a fiber laser is the master oscillator for the 192 beams of the NIF laser: Small pulses from the fiber laser are amplified up to megajoule size in large slabs of doped glass.

In modelocked fiber lasers, the repetition rate depends on the length of the gain material, as in any kind of modelocking scheme, while pulse duration depends on the gain bandwidth. The shortest achievable oscillator pulses are in the 50 fs range, with more typical durations in the 100 fs range. Shorter pulses can be generated in oscillator-amplifier systems with external chirped-pulse amplification and subsequent pulse compression.

An important difference exists between erbium- and ytterbium-doped fibers, resulting from the fact that the two are operating in different dispersion modes. Erbium-doped fibers emit at 1550 nm, which is in the anomalous-dispersion region; this allows the production of solitons. Ytterbium-doped fibers are in the positive or normal dispersion realm; as a result, they generate strongly chirped pulses. As a result, a chirped fiber Bragg grating may be needed to dechirp the pulses to compress the pulse length.

There are a number of ways to modify fiber-laser pulses, particularly for things like picosecond ultrafast research. Photonic-crystal fibers can be made with extremely small cores to produce strong nonlinear effects for applications such as supercontinuum generation. In contrast, photonic crystals also can be made with very large singlemode cores to avoid nonlinear effects at high power.

Bendable large-core photonic-crystal fibers are being created for high-power applications; one of the tricks being looked at is intentionally bending such a fiber enough that any undesired higher-order modes will go away, leaving only the fundamental transverse mode. Nonlinearities allow harmonics to be generated; sum and difference frequency mixing can create higher frequencies and shorter wavelengths. Nonlinear effects can also produce pulse compression, leading the way to the production of frequency combs.

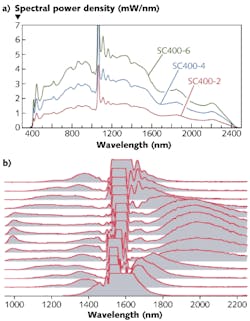

In a supercontinuum source, very short pulses produce a broad continuous spectrum via self-phase modulation. In one example, initial 6 ps pulses at 1050 nm (from a ytterbium fiber laser) produces a spectrum ranging from the ultraviolet to beyond 1600 nm, with some irregularity across the spectrum (see Fig. 3). Another supercontinuum source, this one working in the IR, is pumped with an erbium fiber laser at 1550 nm. In this case, the spectrum of the supercontinuum source varies with pulse width. This design achieves a range of more than an octave, ranging out past 2200 nm.High-power fiber lasers

The industrial market is now the largest market for fiber lasers; much of the action right now is at the kilowatt-class power level. Particularly interesting is their use in automotive work. The automotive industry is moving to high-strength steel to produce cars that meet durability requirements but are relatively light for better fuel economy; the problem is how to cut the high-strength steel. And that’s where they turn to fiber lasers. It’s very difficult, for example, for conventional machine tools to punch holes in this kind of steel; however, fiber lasers (and other types of lasers as well) can easily cut these holes.

Fiber lasers have some advantages over other lasers for materials processing. For example, the near-IR wavelengths of fiber lasers are absorbed well by metals. The beam can also be delivered by fiber, which allows a robot to easily move the beam focus around for cutting and drilling.

The highest single-mode power available from a fiber laser is 10 kW, from IPG Photonics. In the system, a master oscillator produces a kilowatt of optical power that is fed into an amplifier stage pumped at 1018 nm with light from other fiber lasers. The entire laser system is about the size of two refrigerators.

The highest multimode power reached is 50 kW, also by IPG Photonics. The system relies on incoherent beam combination, so it’s not a super high-quality beam (beam parameter product of 10, M2 of 33). This laser has been shipped around the country and has operated at 50 kilowatts in five states. This is the kind of durability that makes fiber lasers attractive for industry.

Other applications exist for fiber lasers in high-power cutting and welding—for example, replacing resistance welding for high-speed sheet steel, solving the problem of material distortion caused by resistance welding. Power and other feedback controls allow fiber lasers to cut a very precise curve, especially going around corners.

Drilling concrete

A 4 kW multimode fiber laser has been used to cut and drill concrete. Why would one want to cut concrete with a laser? When engineers are attempting to earthquake-proof existing buildings, they want to be very careful with the concrete. However, they need to put things like rebar in it to bolster its strength so it won’t just crumble if an earthquake hits. Conventional percussion drilling can crack and weaken concrete, but fiber lasers cut it without fracturing.

Q-switched fiber lasers are used, for example, in pulsed materials working, such as laser marking or working semiconductor electronics. The are also used for lidar; a module green module about the size of one’s hand, contains an eye-safe erbium fiber laser with a 4 kW peak power, a 50 kHz repetition rate, and a 5-to-15-ns pulse duration.

There is a lot of interest in smaller fiber lasers for micro-and nanoscale machining. For surface ablation, if the pulse duration is made shorter than about 35 ps, then there is no material splatter, just ablation, eliminating the formation of kerfs and other unwanted artifacts on the metal being cut. Pulses down in the femtosecond regime and produce nonlinear effects that are insensitive to wavelength and don’t heat the surrounding area, allowing material work without damaging or weakening the surrounding area. In addition, holes can be cut with high aspect ratios—for example, rapidly (within a few milliseconds) drilling small holes through 1-mm-thick stainless steel using 800-fs pulses at a 1 MHz repetition rate.

One can also do surface machining of transparent materials—for example, the human eye. To cut flaps for LASIK surgery, femtosecond pulses are tightly focused with a high-numerical-aperture lens onto a spot below the eye’s surface, causing no damage at the surface, but breakdown of the eye material at a controlled depth. The surface of the cornea, the smooth surface of which is important for vision, escapes unharmed. The flap, separated from underneath, can then be pulled up for ablative excimer-laser lens shaping. Other medical applications for picosecond and femtosecond fiber lasers include shallow-penetration surgery in dermatology, and use in certain kinds of optical coherence tomography (OCT).

Scientific applications of femtosecond fiber lasers include laser-induced breakdown spectroscopy, time-resolved fluorescence spectroscopy, and general materials research. And fiber lasers are used to produce femtosecond frequency combs, valuable in metrology as well as general research. One realistic near-term application for easily generated frequency combs will be atomic clocks for future-generation GPS satellites, resulting in much finer position resolution on the ground—a boon not just for knowing exactly where you are on the street, but also for automated equipment such as robot tractors that need to know they’re tilling between, not on, rows of corn based on GPS measurements.

What's coming

As for other research applications, there is much out there that is still being explored. For example, one thing being developed largely for military work, but with potential other applications, is the combining of fiber-laser beams to get a high-quality single beam, either through coherent or spectral combination. The result will be higher power in a single-transverse-mode beam.What are we seeing as trends? We’re seeing very rapid growth in the fiber-laser industry market—particularly in the automotive area. We’re also seeing the replacement of non-fiber lasers with fiber lasers. Beyond general improvements in cost and performance, ever-more-practical femtosecond and supercontinuum sources are appearing. Fiber lasers are pushing beyond the particular niches they’ve already found into other niches; as a result, they are a force in the improvement of other types of lasers as well.

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.