NOVEL LASERS: Broadband laser-driven plasma source spans nearly 2000 nm

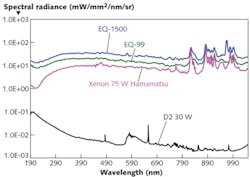

Energetiq (Woburn, MA) has developed a laser-driven plasma light source for spectroscopic and imaging applications that delivers broadband spectral output from 170 nm in the deep-ultraviolet (deep-UV) region through the visible and into the infrared (IR) up to 2100 nm. The EQ-99 laser-driven light source (LDLS)—with electrodeless operation—is up to 10 times brighter with 10 times the lifetime and a broader spectral bandwidth than traditional arc lamps (see figure).

A bright, small spot

The LDLS uses a continuous-wave (CW) laser diode with a wavelength of approximately 1 μm focused to a small spot inside a xenon-filled bulb. The lack of electrodes for operation leads to higher gas temperatures, which increases efficiency (especially in the UV) and removes the major source of traditional lamp degradation and failure. This combination of high brightness and a small plasma spot size—approximately 100 μm in diameter—translates to efficient light coupling to narrow spectrometer slits and very small optical fibers, or collimation into low-divergence beams.

In traditional approaches such as xenon or mercury-arc and deuterium lamps, the brightness, UV power, and lamp lifetime are limited by the use of electrodes that couple power to the plasma. The electrodes limit the brightness in part by limiting the temperature of the plasma, and, since the electrodes run hot, they continuously erode, depositing electrode material on the bulb wall. This redeposition of electrode material causes the output of the lamp to decrease continuously, forcing a lamp replacement perhaps every 1000 hours. And xenon, mercury, and deuterium arc lamps typically have arc sizes in the millimeter range, reducing the efficiency of optical coupling to sub-millimeter-width spectrometer slits or sub-millimeter optical fibers. But by using a laser to directly heat the plasma, the electrodeless LDLS technology creates a small, high-brightness plasma for more efficient and higher-intensity coupling with a 10,000 hour lifetime.

Expanding applications

The concentrated LDLS output is enabling new applications such as high-performance liquid chromatography (HPLC), where users are demanding highly sensitive detection with smaller and smaller sample volumes. These smaller sample volumes drive the dimensions of the detection flow cell to the 100 μm range, limiting the optical throughput when using traditional deuterium lamps. In this application, the LDLS couples readily to the flow cell, providing up to two-orders-of-magnitude improvement in signal. In addition, a single LDLS can replace the often multiple light sources needed to cover a broadband application.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.