Researchers at J. Stefan Institute and the University of Ljubljana (both in Ljubljana, Slovenia) have demonstrated for the first time fully tunable lasing from their three-dimensional (3D) or omnidirectional-lasing dye-doped, cholesteric liquid-crystal (CLC) microdroplet-based microlaser.1 The lasing wavelength is tuned by varying the temperature of the lasing medium.

A radial Bragg (onion) resonator

Although microlasers (or microcavity lasers or nanolasers) have been created using whispering-gallery mode designs, quantum dots, and even surface plasmons and nanowires, the 3D tunable laser is created using CLC microdroplets (15 to 50 μm in diameter) embedded in an isotropic carrier fluid. By dispersing a small amount of the CLC mixture in a nonmiscible fluid such as glycerol, the droplets spontaneously self-assemble in fractions of a second.

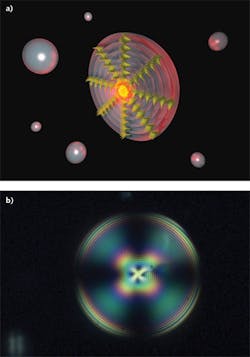

The chirality of the CLC causes a helical twisting of CLC molecules when moving from the center of the CLC microdroplet outward to the surface. This results in a strong modulation of the refractive index in the radial direction, creating a Bragg onion-shaped optical microresonator (see figure). Because of the full rotational symmetry of the layered onionlike structure, the microcavity has a photonic (forbidden) gap for photons emitted in the radial direction. When optically pumped, dye molecules dispersed inside the CLC cavity emit light that the Bragg cavity reflects back into the center. Above the threshold, lasing occurs in all directions. The lasing wavelength depends solely on the helical pitch of the CLC molecules inside the cavity and can be tuned over tens of nanometers by simply changing the temperature. Until now, tunable lasing in a 3D microlaser had not been demonstrated.

3D lasing and tunability

To demonstrate tunable lasing from a 3D microlaser, the researchers prepared two different dye-doped CLC liquid solutions and dispersed small amounts (typically 1%) of each in glycerol, which has a high-enough refractive index to suppress the whispering-gallery modes from a low-index CLC. The spherical droplets that formed were then examined from a sealed planar glass cell consisting of two microscope slides with 1 mm thickness separated by spacers to create a 150 μm thick cell.

The alternating light-dark concentric shells of the "onion" (due to the radial modulation of the index of refraction) for cholesteric droplets having a helical period in the micrometer range are clearly seen with a microscope. Droplets with diameter smaller than 100 μm typically had a perfectly spherical shape. A single spherical CLC microlaser was then illuminated by a Q-switched, doubled Nd:YAG laser (pulsewidth 1 ns, repetition rate 200 Hz, maximum 10 μJ pulse energy) focused to a beam waist of approximately 100 μm to match the droplet diameter.

While increasing the pump energy, the microlaser suddenly began lasing at approximately 600 nm, with bright red emission at the center of the droplet. The laser has a typical 0.1 nm linewidth and is neither linearly nor circularly polarized. Placing the mixture inside a cylindrical glass tube and measuring emission around the tube confirmed uniform illumination in all directions. Furthermore, the emission wavelength could be tuned in a 35 nm range around the nominal 600 nm lasing wavelength simply by changing the mixture temperature. Tuning was almost linear with temperature (3.5 nm/K) and completely reversible.

"A host of applications is possible with a tunable, 3D-emitting laser material, such as remote and contact-less sensing and internal-3D-source holography," says professor Igor Muševic from the J. Stefan Institute and the University of Ljubljana. "These tunable 3D-emitting microlasers are the result of a long-term project on photonic devices, based on soft matter. We anticipate that tunable optical microdevices and new coherent light sources could be made from coupled arrays of 3D fluid microlasers. Future applications aside, for me, as a physicist, these liquid microlasers are just beautiful objects, built on very simple principles."

REFERENCE

1. M. Humar and I. Muševič, Opt. Exp., 18, 26, 26995-27003 (Dec. 20, 2010).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.