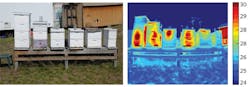

Scientists now have a new tool to study the alarming collapse of honeybee populations: a noninvasive long-wave infrared (LWIR) imaging method from researchers at Montana State University (Bozeman, MT) and the University of Montana (Missoula, MT) that uses a radiometrically calibrated camera signal to noninvasively estimate the number of bees within their hives, reducing hive stress and potential queen mortality.

Using an LWIR camera with an uncooled 324 × 256 pixel microbolometer array, multiple hives were imaged at a distance of 3 to 4 m. The images do not provide detailed interior structures; instead, images have sufficient resolution to observe the spatial variance of hive radiance, which is related to the approximate hive population. Radiometric stability in the images is maintained with calibration algorithms that track and compensate for changes in the camera response due to changes in temperature (a large-area blackbody source among the hives was sometimes used to verify calibration). Passive thermal images of dozens of hives were recorded multiple times in different weather conditions both day and night. Image-processing techniques then correlate thermal signatures with bee counts based on calibration data. The same researchers also recently showed that it is possible to use light detection and ranging (lidar) to map flying honeybees conditioned to identify land mines in a mine field.

Contact Joseph A. Shaw at [email protected].

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.