THIN-FILM COATINGS: Military laser technologies challenge optical-coating manufacturers

TREY TURNER and MARK DAMERY

Optical coatings for military applications present a particularly demanding set of requirements for the thin-film manufacturer, usually revolving around exceptional optical performance in particularly harsh environments. These can include high laser damage threshold, wide angular acceptance, excellent performance at several widely spaced wavelengths, low wavefront distortion, spectral stability in the presence of large swings in temperature and humidity, and good mechanical durability.

The single biggest military application for lasers is in rangefinding and target designation. Rangefinding, which is accomplished with a time-of-flight measurement, is usually performed using a pulsed Nd:YAG laser with output at 1064 nm, and sometimes also at an “eye-safe” wavelength longer than 1.5 µm. Eye-safe wavelengths are typically produced with a semiconductor laser, an erbium-glass laser, or by converting the Nd:YAG fundamental wavelength using an optical parametric oscillator (OPO).

Target designation involves “painting” an intended target with a laser spot; a detection system on laser-guided munitions (typically a bomb or a missile) senses the laser illumination and uses it to direct the weapon’s flight path, thus homing in on the laser spot. The laser beam is modulated with a unique code that enables each laser-guided weapon to distinguish among multiple targets that are being simultaneously illuminated. Designators typically work at 1064 nm, but at a higher power than rangefinding in order to maximize signal-to-noise ratio.

Many targeting systems also incorporate one or more other imaging or vision systems operating at other wavelengths. These include visible-wavelength telescopes, night vision or thermal imagers, and mid-infrared (IR; 3–5 µm) forward-looking infrared (FLIR) systems; the mid-IR band is useful because these wavelengths are transmitted well even in the presence of smoke, fog, haze, and clouds.

These systems are supplied in a variety of different forms, from handheld units that can be used in forward position and covert operations to larger pod or turret assemblies belly-mounted on aircraft. However, in all cases, minimizing overall package size and weight is critical. As a result, they are often configured so that the laser, a visible-wavelength sighting system, and a FLIR system use some of the same optics along a common beam path. This is referred to as multispectral operation. The long distances (up to 10 km) over which the targeting/designating laser beams are propagated also necessitate tight specifications for wavefront distortion.

Coating requirements

The demanding requirements of designator/rangefinder optics complicate both the design and fabrication of their thin-film coatings. For example, it is particularly difficult to design coatings that function in the visible or at 1064 nm while simultaneously operating in the mid-IR. This is because there are few coating materials that work well over both these widely spaced wavelength bands.

In addition to wide spectral operation, these coatings often must function over large angular ranges. Examples are beamsplitters with large tolerances around the nominal incidence angle, and lenses that work at a low f-number. Designing such coatings becomes even more challenging when large angular range and multispectral operation is combined with tight specifications for polarization insensitivity.

Deposition of these complex coatings also presents several significant challenges. One reason is that a multispectral coating essentially consists of a stack of several layer groups, each of which serves a specific function. For instance, one component of the stack might be an antireflection coating for 3–5 µm, while another could be a high reflector at 1064 nm. If any one of these groups is not fabricated within tolerances, then the entire coating must be rejected. Thus, yields decrease as the functionality required within the coating increases.

The need to incorporate numerous layers in order to achieve advanced functionality can also result in relatively thick films that may exhibit high mechanical stress. That can be a problem when the optical-systems designer specifies components with a relatively high aspect (diameter to thickness) ratio to minimize weight. High coating stress can actually warp these thin components out of their original shape, increasing the wavefront distortion of the component and overall system.

The drive to minimize system size and weight may also motivate the optical designer to scale down component diameters. However, shrinking the diameter of a given power laser beam causes an increase in its power density. So laser damage threshold often becomes a concern. This is especially true at the target designating wavelength, which often works at relatively high powers.

Finally, the use conditions of battlefield optics present a unique set of challenges. In particular, these systems may experience wide swings in temperature and humidity and are sometimes exposed to salt spray, smoke, or other airborne contaminants.

Design and deposition approaches

The exact way that coating specifications are stated can significantly impact production cost. So, an important first step in the coating design process is to confirm with the user that specifications accurately reflect actual performance targets. For example, in the case of polarization insensitivity for beamsplitter coatings, meeting an average reflectance specification (for each polarization) over the entire angular range is significantly easier (and less costly) than achieving a set value right up to the most extreme incidence angles.

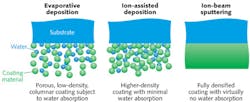

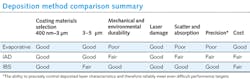

In terms of deposition, there are three basic methods currently in common use: thermal evaporation, ion-assisted deposition (IAD), and ion-beam sputtering (IBS). Each has advantages and disadvantages (see Fig. 1).

Thermal-evaporation methods (either using resistive heating or electron beams) are by far the most widely used. Their advantages are that they work with a very wide range of materials, enabling coating optimization anywhere from the deep UV through the far IR, and that they are the lowest-cost deposition methods. The most important downside of thermal methods is that they produce porous coatings that can subsequently absorb moisture, thus changing the effective refractive index of the layers. This shifts the transmission/reflection response of the film, making it difficult to hold the desired multispectral performance targets when exposed to changes in ambient temperature and humidity. Furthermore, porous coatings are prone to defects that lead to lower surface quality and can act as sites for laser damage. Evaporative coating also produces the poorest mechanical durability of all deposition techniques.Ion-assisted deposition is a variant of evaporative deposition that delivers substantially more dense films, although some water absorption is still possible. Thus, it represents a step up in terms of coating stability and durability, while working with essentially the same set of materials. As a result, IAD often represents the best balance between durability and performance, particularly for coatings in the 3–5 µm range.

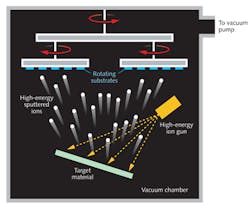

Ion-beam sputtering produces fully densified thin films that are effectively completely impervious to water absorption, and thus very stable in the presence of environmental changes (see Fig. 2). Another important feature of IBS deposition is that it deposits materials with highly reproducible refractive-index characteristics. When coupled with the ability to accurately control layer thickness, this enables high coating precision, or the ability to consistently match the actual coating characteristics with the desired design specifications. This is particularly valuable in the production of multispectral coatings, as well as for meeting tight targets for broad angular range and specific polarization characteristics.The biggest drawback of IBS is that it works with a more limited range of materials than evaporative methods. This isn’t a problem in the visible and near-IR (NIR), but does become an issue in the 3–5 µm range because neither sulfide nor fluoride coating materials are easily compatible with IBS.

Another potential problem with all densified coatings is that they can contain stress that may negatively impact wavefront distortion. Manufacturers have developed various methods to control this. For example, post-coating annealing can be used with some materials to reduce internal stress. Another approach is prefiguring, where an optic is purposely fabricated with a surface error that is then corrected by the coating-induced stress. Also, a second coating is sometimes put on the back of a substrate to balance the stress of the frontside coating.

It’s also critical that the coating manufacturer be able to measure what it fabricates. Some spectrophotometers may not support measurement at steep angles, or be able to characterize low reflectivities over a wide angle and both polarization states, or characterize absorption levels. In these cases, alternative instrumentation, such as laser photometers or cavity-ringdown loss measurement, must be used.

Designing for high power

For applications with high laser-beam intensities, managing laser-damage threshold is critical and requires both careful design and good metrology. Specifically, the designer must carefully analyze and manage the electric-field profile throughout the layer stack. Coatings with high field peaks at layer interfaces should be avoided. In addition, for multispectral coatings, it’s best to put the high reflector for the highest-power wavelength on the top of the stack, so that the high-power beam doesn’t penetrate far into the coating. It’s also very helpful to have in-house laser damage testing capabilities, enhancing the ability to identify process factors that may lower damage threshold.

Producing optical coatings for military applications is a unique challenge, as these coatings require accommodating more factors than are typically encountered for most commercial applications. But military optics are just like any other OEM components in that tighter specifications virtually always mean higher costs. Consequently, it is critical to strike up a dialogue with potential coating vendors to establish a realistic set of specifications that deliver the necessary performance without driving up cost unnecessarily. Moreover, no single coating method is ideal for all military applications, so it is best to work with a supplier who has access to a comprehensive suite of deposition and metrology capabilities.

Trey Turner is chief technology officer and Mark Damery is vice president and general manager of worldwide sales at Research Electro-Optics (REO), Boulder, CO; e-mail: [email protected]; www.reoinc.com.