A single view yields 3D x-ray diffractive images

Researchers at the University of California–Los Angeles (Los Angeles, CA), the University of Colorado at Boulder (Boulder, CO), and the University of North Texas (Denton, TX) have for the first time demonstrated ankylography—3D coherent x-ray diffractive imaging that could find applications in imaging thick or embedded structures where slicing for electron or confocal microscopy is not feasible. From the Greek words "ankylos" and "graphein," ankylography translates to "curved writing" and can produce nanometer-resolution images in 3D from a single, intense femtosecond x-ray pulse from a free-electron laser.

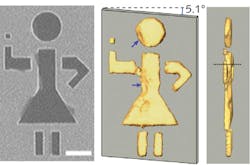

Using a 47 nm tabletop soft x-ray laser spatially filtered to produce a beam with full spatial and temporal coherence, the research team focused the beam using two multilayer mirrors onto a test sample. The researchers then measured the x-ray diffraction pattern on a large-area x-ray CCD a mere 1.7 cm away. Because the high-numerical-aperture diffraction pattern recorded on a flat CCD detector is distorted, mapping this flat pattern onto a curved Ewald sphere reveals 3D information for the object since the sphere is a hemispherical slice through the 3D reciprocal space of the test object. Using a phase-retrieval algorithm, a 3D rendering of a 7 µm tall stick figure cut from 100 nm thick gold on 100 nm thick silicon nitride was recovered; however, the technique requires accuracy improvements before it can be practically applied. Contact Jianwei Miao at [email protected].