FIBERS FOR FIBER LASERS: Structured fiber advances short-pulse laser performance

PHILL AMAYA

A growing number of high-precision materials processing applications require short-pulse lasers. Such applications include microvia hole drilling in PCBs and flex circuits, semiconductor memory repair, solar cell edge isolation and thin-film patterning, and sapphire substrate scribing in LED manufacturing.1 All of them are characterized by increasing miniaturization and/or relentless pressure to reduce manufacturing costs.

Miniaturization and diminishing feature size are the primary reasons for using short-pulse lasers. Pulse lengths of less than 80 ns are typically required to minimize the heat-affected zone at the work piece and consequent potential damage to nearby components. Micron-scale features also favor shorter wavelengths because these wavelengths can achieve a smaller focused spot size. Material absorption characteristics are also a key consideration in determining laser wavelength.

In addition, as feature sizes diminish, there are more features to process per device or per unit area so laser pulse repetition rate must increase or manufacturing cycle time per device will grow. This requirement is amplified when the substrate upon which features are fabricated simultaneously increases in size. The minimum feature dimension of a semiconductor memory chip, for example, has fallen from 150 to 60 μm over the last 10 years. At the same time the silicon wafer has increased in size from 200 to 300 mm. Hence the possible number of features that can be printed on a single wafer has jumped by a factor of 14. In this example, the reduction in feature size has also driven the process to adopt UV wavelengths for a smaller spot size. These advances have driven laser developers to increase average output power by a factor of 10 at the fundamental wavelength of around 1.0 μm while migrating the application wavelength to 355 nm. Similar trends are evident in other microelectronics applications. Solar cell processing is driven by increasing surface areas and reducing processing time.

The vast majority of nanosecond-pulse applications today are served by diode-pumped solid-state (DPSS) lasers. The performance of these systems reflects more than 20 years of continuous innovation and is largely unmatched by any other laser technology. There are signs, however, that some applications may be advancing beyond the practical capabilities of DPSS lasers. Smaller spot requirements and material issues are driving pulse lengths to the picosecond regime, but the necessary per-pulse energy must be maintained even as pulse repetition rates increase. Creative solutions are emerging, such as "dual-beam" technology where the output from two pulsed sources is multiplexed to deliver twice the pulse repetition rate. Another "hybrid" approach is based on a low-power, high-pulse-repetition-rate fiber laser that seeds a DPSS amplifier in an approach that splits the pulse generation work from the power amplification. Though these solutions are being deployed, they do add cost and complexity, and their path for additional scaling may be somewhat limited.

Fiber lasers

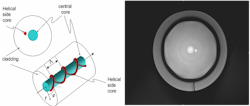

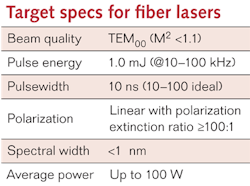

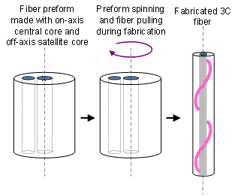

Among the solutions proposed for a next-generation source to address current and developing short-pulse applications is the fiber laser. Key target specifications are summarized in the table. Fiber lasers are attractive for short-pulse applications because of their high single-pass gain, which enables simple amplifier designs and straightforward average power scaling. The difficulty comes in scaling the fiber core size for the high-peak-power operation needed to achieve the required pulse energy and duration. Without core size scaling, nonlinear optical effects cause spectral broadening and output power instabilities. Using 20 μm core double-clad fiber (DCF), commercial fiber lasers available today promise up to 25 kW of peak power in a 10 ns pulse, yielding 25 W of average power at 100 kHz operation. This is only one-quarter of the average power targeted in the table and about half of what current DPSS lasers can deliver. A promising solution with potential for further power scaling involves a uniquely structured fiber named chirally coupled core or 3C fiber.2An important attribute of 3C fiber is that its performance does not depend on specific bending. This is in contrast to standard large-mode-area fibers that achieve single-mode performance by careful coiling to exploit the differences in bend-induced losses between the fundamental mode and higher-order modes—a method that's effective up to about 25 μm core diameters. For larger core sizes it becomes increasingly ineffective.3 This technique is also problematic for beam delivery and use in fiber components. Since modal discrimination is not a function of fiber bending, 3C fiber can be used effectively in coiled or straight configurations with active or passive fibers.

Chirally coupled core fibers with core diameters of 35 μm have been made with and without ytterbium (Yb3+) doped cores for use as gain fibers and in the construction of passive fiber components. Laboratory testing of fiber performance in a MOPA (master oscillator power amplifier) configuration has produced more than 100 W of average power, with 10 ns pulses and 100 kW peak power at 100 kHz pulse repetition rate (see Fig. 4).4Polarization

It is important to recognize that the largest applications for short-pulse lasers require visible and UV wavelengths, so a suitable fiber laser source must have stable polarization output. Polarized light from optical fibers is typically created by strong birefringence resulting from directionally oriented material stress. This can be achieved with stress rods in the fiber and works well for fiber core diameters of less than 10 μm. As fiber core size increases it becomes more difficult to produce uniform stress across the larger cross-section of the fiber core, meaning that achieving high polarization contrast is also difficult. The resulting polarization performance is very sensitive to thermal and mechanical perturbations, which creates output instability.

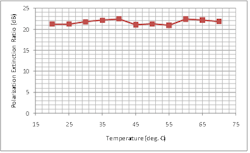

In contrast, 3C fiber designs have been developed that exploit the manufacturing process and fiber structure to produce very low birefringence fibers. These low-bi fibers very faithfully reproduce at their outputs the polarization state of the input light (see Fig. 5).Shrinking component features and relentless pursuit of lower manufacturing costs will continue to drive demand for higher-performance, short-pulse lasers. Our 3C fiber is one of the most recent innovations that can enable lasers to meet those demands with scalability for further performance advances. Larger-core single-mode fibers offer performance potential that extends well beyond the trajectory of current applications in materials processing. Three examples where applications focused research is already underway using 3C fiber are 1) directed energy weapons, 2) laser-produced plasma extreme UV lithography, and 3) ultrafast spectroscopy.

In directed energy applications, larger fiber cores are needed to achieve targeted CW powers while maintaining narrow spectral width with single polarization. Fiber lasers are desirable here because of their high electrical-to-optical efficiency, compact size, and potential for more robust assembly. Extreme UV lithography is moving toward high-volume semiconductor production based on large CO2, pulsed laser sources. Research based on large-core single-mode fibers suggests a more efficient, compact, and scalable laser source might be constructed by spectrally combining high-power pulsed fiber lasers.5 Finally, large-core, single-mode fiber is a key element in efforts to make a compact and robust source for practical ultrafast spectroscopy systems.

REFERENCES

- S. Geiger, "Tailoring the performance of q-switched, solid state lasers – why and how," Solid State Lasers XV: Technology and Devices, Proc. SPIE, Vol. 6100, pp. 458–466 (2006).

- A. Galvanauskas, M.C. Swan, C.H. Liu, "Effectively-Single-Mode Large

Core Passive and Active Fibers with Chirally-Coupled-Core structures," CLEO/QELS Conf. and Photon. Appl. Sys. Technol., OSA Technical Digest (CD), Optical Society of America, paper CMB1 (2008). - M. Li, X. Chen, A. Liu, S. Gray, J. Wang, D. Walton, L. Zenteno, "Effective Area Limit for Large Mode Area Laser Fibers," OFC/NFOEC, OSA Technical Digest (CD), Optical Society of America, paper OTuJ2 (2008).

- C. Liu, S. Huang, C. Zhu, A. Galvanauskas, "High Energy and High Power Pulsed Chirally-Coupled Core Fiber Laser System," in Advanced Solid-State Photonics, OSA Technical Digest Series (CD), Optical Society of America, paper MD2 (2009).

- K.-C. Hou, S. George, A.G. Mordovanakis, K. Takenoshita, J. Nees, B. Lafontaine, M. Richardson, and A. Galvanauskas, "High power fiber laser driver for efficient EUV lithography source with tin-doped water droplet targets," Opt. Exp. 16, pp. 965–974 (2008).

Phill Amaya is CEO of Arbor Photonics Inc., Ann Arbor, MI 48105; e-mail [email protected]; www.arborphotonics.com.

![FIGURE 2. Calculated modal loss for a specific 3C fiber design with core diameter of 35 μm shows that for a helix period of 9 mm, loss of less than 0.2 dB/m is achieved for the fundamental LP01 mode and more than 100 dB/m for higher order modes [2]. FIGURE 2. Calculated modal loss for a specific 3C fiber design with core diameter of 35 μm shows that for a helix period of 9 mm, loss of less than 0.2 dB/m is achieved for the fundamental LP01 mode and more than 100 dB/m for higher order modes [2].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2021/03/1007lfw7_fig2.60468078d3cbd.png?auto=format,compress&fit=max&q=45?w=250&width=250)

![FIGURE 4. Tests on the 3C fiber demonstrate its slope efficiency (70%) and beam quality. Here the fiber achieved an M2 of 1.07 [4]. FIGURE 4. Tests on the 3C fiber demonstrate its slope efficiency (70%) and beam quality. Here the fiber achieved an M2 of 1.07 [4].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2021/03/1007lfw7_fig4.604680f6eae4f.png?auto=format,compress&fit=max&q=45?w=250&width=250)