ADAPTIVE OPTICS: High-power guidestar lasers are ready for next-generation AO astronomy

With its virtual elimination of the effects of atmospheric turbulence, adaptive optics (AO) has allowed leading ground-based astronomical telescopes to resolve almost as well as if they were operating in space. Some optical telescopes now being planned will be far too large to loft into space; AO will be essential to the function of these mammoth ground-based instruments.

Most AO systems for telescopes rely on the existence of a bright pointlike source of light that exists above the turbulence of the atmosphere and appears somewhere in the telescope's field of view; the point source is used as a "guidestar," whose wavefront aberrations are measured and then used as input for the AO correction. The first guidestars were actual stars, but the limited number of bright stars means that only small portions of the night sky could be viewed through these AO-corrected telescopes.

A much more versatile approach is to use a sodium-guidestar laser emitting at the 589 nm wavelength of atomic sodium, aiming the beam so that it creates a point source of light in the mesosphere. The resulting artificial guidestar can be placed wherever desired, opening up the whole sky to the sharpness of AO-corrected imaging. High-power guidestar lasers have big advantages, but it is not easy to create a reliable, easy-to-use, industrial-quality laser with an output of tens of watts at 589 nm. It is not impossible, though, as the two following articles illustrate. —John Wallace

50 W guidestar laser is injection-locked, frequency-summed

CRAIG DENMAN

Next-generation telescopes, now in the design stage, will make use of AO to achieve resolution competitive with space-based telescopes. The sodium-guidestar lasers required in these designs must have power exceeding 25 W, diffraction-limited beams, and a sodium D2a line wavelength of 589.15905 ±0.00005 nm. When that power and precise wavelength are incident on the 90-km-high mesospheric atomic sodium layer (a residue from meteors), the sodium will fluoresce strongly enough to give the AO system the distant, pointlike reference it needs.

Dye lasers and frequency-summed modelocked solid-state lasers are currently used as guidestar lasers. These lasers have enabled astronomical observations that otherwise would not have been possible. However, more power and improved hands-off reliability are needed.

In 2001, a group at the U.S. Air Force Research Lab Starfire Optical Range proposed a new sodium-guidestar laser design. The mission of the Starfire Optical Range is termed "space situational awareness"—the observation of satellites in orbit; as a result, this organization is a pioneer in AO. The new laser design was termed a frequency-addition source of optical radiation (FASOR).

The Starfire FASOR system produces light at 589 nm by frequency-summing two continuous-wave Nd:YAG lasers, one emitting at 1064 nm, the other at 1319 nm. The Nd:YAG lasers reach high single-frequency power by using the injection-locking technique, in which a low-power single-frequency beam is resonantly amplified. The two wavelengths are summed in the nonlinear material lithium triborate (LBO), again using resonant techniques. The Starfire FASORs use active laser components provided by JDSU Commercial Lasers (Milpitas, CA), based on JDSU's nonplanar ring-oscillator and direct-coupled-pump technologies.

By 2005, the FASOR was in regular use, and the AO community was impressed by the large amount of light returning from the sodium layer and by the consistent and simple operation of the laser. The high return was due partly to the laser's power, which exceeded 50 W, and partly to its extremely narrow and stable single-frequency linewidth, which led to unexpectedly high fluorescence efficiency (see Fig. 1).

In 2008, FASORtronics LLC was founded by Craig Denman and Paul Hillman, formerly members of the Starfire group, and by Tom Kane, formerly of JDSU. The goal of FASORtronics is to commercialize the single-frequency FASOR technology for sodium-guidestar lasers. Supported by contracts from major observatories, FASORtronics has created a design appropriate for use in next-generation telescopes.

The FASORtronics sodium guidestar laser is capable of producing 50 W with near-perfect beam quality and with wavelength accuracy limited only by measurement capability. Integrated into the design is an optional second frequency that can be generated for D2b population pumping to enhance guidestar radiance efficiency. The laser head and power supply enclosures can be separated by up to 30 m or more, or can be stacked together to form a complete system 600 × 900 × 1200 mm in height. The entire system can tolerate a changing gravity orientation, allowing it to be mounted on the highest and most mobile structures of a telescope.

Rapid tuning of the 589 nm frequency on and off the sodium absorption line, absolute frequency calibration using a wavemeter and sodium cell, power control, and optical alignment can all be commanded remotely through a graphical user interface.

Craig Denman is a founder of FASORtronics LLC, P.O. Box 50370. Albuquerque, NM 87181-0370; e-mail: [email protected]; www.fasortronics.com.

Coherently combined, frequency-doubled RFAs create high-power guidestar beam

WALLACE R. CLEMENTS and WILHELM KAENDERS

Recent progress in high-power visible-laser technology has opened a new avenue to the creation of laser guidestars for next-generation astronomical observatories. A combination of established narrowband frequency-stabilized laser-diode technology, providing a seed source in the near infrared, with high-power fiber-amplifier technology and efficient, robust frequency conversion to the orange, results in a compact source for AO systems of modern telescopes. This source is the result of a successful collaboration between MPB Communications of Canada and Toptica Photonics of Germany.

Triggered by the breakthrough results of the European Southern Observatory (ESO; Garching, Germany) using a laser architecture based on high-power, narrow-linewidth Raman fiber amplification, we began working under an ESO-funded contract to design a system suitable for deployment as a laser guidestar. After four years of research and development, the ESO Laser Systems Department had successfully demonstrated, for the first time, a narrowband, non-polarization-maintaining high-power Raman fiber amplifier (RFA) on a breadboard tabletop.

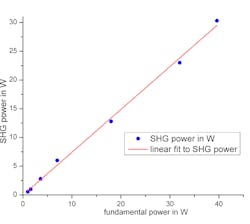

When combined with Toptica's free-space coherent beam combination (CBC) and the latest compact SHG resonator design, an output of more than 20 W at 589 nm was demonstrated (see Fig. 2).1, 2 To develop a deployable laser guidestar, we were faced with new challenges such as advancing the RFA technology to use polarization-maintaining fibers, developing a high-power polarization-maintaining fiber laser to pump the RFA, implementing an all-in-fiber CBC scheme, and designing a compact and reliable laser system for remote operation at high altitudes.The resulting laser enables up to 30 W of continuous-wave optical power precisely at the sodium resonance line at 589 nm, with a linewidth less than 1 MHz and tunability of 30 GHz. Starting from a grating-stabilized diode laser emitting at 1178 nm with a linewidth less than 100 kHz, we simultaneously injection-seed two high-power 1178 nm RFAs developed by MPB. The polarized, coherent, narrowband high-power outputs (22 W in each arm) of the two RFAs are then coherently combined in an actively controlled all-fiber Michelson interferometer, providing an overall combining efficiency greater than 94%.

The resulting 40 W of optical output are launched into a commercial-grade resonant-enhancement cavity for frequency conversion to 589 nm with an efficiency exceeding 75% (see Fig. 3). The robust frequency stability and narrowband performance characteristics of the diode-laser oscillator are passed on to the output of the RFAs, making beam combination and efficient frequency-doubling possible. A final challenge involved the development of a suitable "re-pumper" scheme, required to use the mesospheric sodium atoms in a quasi-two-level configuration to improve optical pumping and laser-guidestar return-flux efficiencies.3 The result fulfills the more than 200 ESO requirements for the four guidestar lasers to be mounted in 2013 as part of the Adaptive Optics Facility of the ESO Very Large Telescope on Cerro Paranal, Chile.The novel laser design, combining a high-precision seed laser diode, Raman fiber amplification, and cavity doubling, is also well suited for the harsher environments of future telescopes (for example, the new Thirty Meter Telescope to be built at an altitude of 4200 m on Mauna Kea, HI).

Acknowledgments

We acknowledge the encouragement and support of ESO, in particular D. Bonaccini Calia, L. Taylor, and Y. Feng. Toptica Photonics and MPB Communications are licensees of the Narrow Band Fiber Raman Amplifier Technology developed and transferred by ESO.

References

- L. Taylor et al., "20 W at 589 nm via frequency doubling of coherently beam combined 2-MHz 1178-nm CW signals amplified in Raman PM fiber amplifiers," CLEO/Europe 2009, postdeadline paper.

- Y. Feng et al., Opt. Exp. 17(21), p. 19021 (2009).

- R. Holzlöhner et al., "Optimization of cw sodium laser guide star efficiency," http://arxiv.org/PS_cache/arxiv/pdf/0908/0908.1527v2.pdf.

Wallace R. Clements is director of engineering and development at MPB Communications, 147 Hymus Blvd., H9R1E9 Pointe Claire, Montreal, QC, Canada; www.mpbc.ca. Wilhelm Kaenders is president of Toptica Photonics, Lochhamer Schlag 19, 82166 Gräfelfing, München, Germany; e-mail: [email protected]; www.toptica.com.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.