Nano-optical antenna is based on radio-frequency design principles

A nano-optical antenna created by researchers at Hiroshima University (Higashihiroshima, Japan) takes the structure of a common form of radio-frequency antenna invented almost a century ago, shrinks it by a factor of more than million, and results in a planar device about the size of a wavelength of light that emits light in a directional beam—a desirable characteristic for planar lightwave optics. The Yagi-Uda radio antenna, sometimes still seen on rooftops in the form of TV antennas, was invented in Japan in 1926; it contains a signal feed, a reflector, and a few directors. The nano-optical version is made of 50 nm thick gold nanorods on glass.

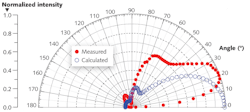

The device's feed element was driven by light from a 662-nm-emitting laser diode and the emitted signal strength as a function of angle was measured. The signal output was very directional, mostly falling within a range of 0° to 20° (the same device without the nano-optical directors emitted in a dipole-like range from about 20° to 160°). So radio-frequency antenna design can be successfully applied to nano-optics—with the one caveat that the response of metal in the optical regime is given by its complex dielectric constant (making design calculations a bit more complicated). Contact Yutaka Kadoya at [email protected].