FIBEROPTIC TEST & MEASUREMENT: Wavelength-selective switches play critical role in agile optical networking

MATTHEW ADAMS

Wavelength-selective switches (WSSs) are a key enabler of reconfigurable optical add/drop multiplexers (ROADMs). With almost all new communication system deployments leveraging ROADM-based agile optical networks (AONs), manufacturing test and component engineers are reviewing their needs and strategies for dense wavelength-division multiplexing (DWDM) module testing—something they have not had to do for a long time.

ROADM and WSS basics

A traditional fixed demultiplexer enforces a clear, fixed relationship between output port and wavelength; each wavelength is assigned a specific output fiber (or port). By contrast, a WSS can direct any wavelength, group, or band of wavelengths to any output fiber through an electrical interface. This dynamic capability has also expanded in most cases to include an attenuation function.

While a demultiplexer is typically built from a few fixed optical elements, a 1 × 5 WSS is functionally equivalent to an integrated module with one 80-channel demultiplexer, 80 variable optical attenuators (VOAs), 80 1 × 5 switches, and five 80-channel demultiplexers. Insertion loss for these next-generation modules can range between 2.5 and 8 dB, depending on the exact functionality and design. The large number of demultiplexing and multiplexing events experienced by a signal traversing the node creates the need for new critical performance and test tolerances on the WSS bandwidths.

Initial implications for the test engineer

The basic measurement processes for fixed DWDM and agile WSS modules are generally the same. However, there are three major areas where the manufacturing engineer must understand the functional differences and develop test strategies to accommodate. The most apparent challenge is the higher number of test states that must be verified, either during manufacture or during design verification. While a fixed demultiplexer can be fully characterized in one to four measurements, the WSS can take hundreds, which puts a premium on rapid measurements. However, because of the wavelength agility of each output port and the potential for interactions between different ports as wavelength patterns are changed, the speed of characterization over multiple output ports (typically between 5 and 40) across the entire telecommunications C (1530–1565 nm) or C+L (C band + 1565–1625 nm) band must be optimized.

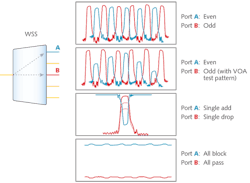

The test engineer must work with the design team or supplier to define test patterns and sequences that can be used to verify performance. It is not possible to test every conceivable state, and test patterns are chosen in order to stress the device. While each device and design will have different performance limitations, some common patterns emerge (see Fig. 1).

The odd/even pattern configures the WSS as an interleaver, sending alternate wavelength slices to two different ports. In this configuration, channel uniformity, band shape, and crosstalk characteristics can be viewed. Although the pattern is simple, the number of port pair combinations can still create many test cases. In this pattern, it is also possible to verify variable optical attenuator (VOA) performance. The third pattern is the single drop, where one channel is isolated from the express path and routed to a different port. This configuration verifies the ability of the WSS to completely remove a channel and ensures minimal residual signal is present when or if the wavelength is added back into the system at a later node. This measurement is often called extinction ratio. The last pattern is the all-block and all-pass state, where base loss and flatness can be verified.

Loss and PDL measurements

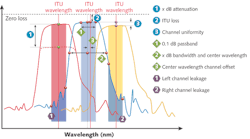

International standards such as the International Electrotechnical Commission (IEC) IEC 61300-3-29 give guidance on the analysis of DWDM modules and can be extended to WSS modules. Key measurements on critical parameters, for example, can be extracted from three channels of a DWDM or WSS (see Fig. 2). For a device in a mode where individual ITU channels are isolated and routed to individual output fibers, one of the unique WSS measurements is attenuation. This is a measurement of the increase in loss at the ITU channel wavelength—a particular value defined by the International Telecommunication Union (ITU)—with the setting of the in-line VOA.ROADM cascades and edge effects

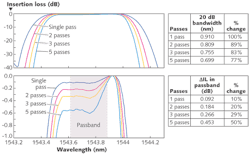

One of the key differences between a DWDM and a WSS is the need for the WSS to operate in cascaded configurations without optical/electronic/optical (O/E/O) regeneration. Today's designers look at multiple ROADM architectures that require 10 or more WSSs in series. With multiple cascaded devices, the impact of filter edge effects become more pronounced due to bandwidth "thinning." As bandwidth narrows, the impact of edge effects from polarization dependent loss (PDL), group delay (GD), and differential group delay (DGD) become more pronounced and therefore difficult to manage. Ensuring tight measurement tolerance on bandwidth measurements requires test systems with precise wavelength tolerances and high dynamic range. While there is pressure to measure faster, wavelength sampling accuracy must remain extremely high.

Cascaded architectures create several issues of importance to the fiberoptic test engineer (see Fig. 3). For example, for five WSS devices measured in series, there is a noted decrease in the effective channel bandwidth—often referred to as bandwidth thinning. In addition, cascaded architectures negatively impact channel flatness. These issues are the driving reasons for ensuring tight tolerances on bandwidth, center wavelength, and ITU offset measurements.Additionally, WSS measurement systems must resolve center wavelength and bandwidth changes as a state of polarization. In single-mode fiber, the polarization state is not controlled. It is likely that the transmission signal will be at a different polarization state as it traverses each WSS in a cascaded design. If the device has a strong center wavelength shift or bandwidth changes with polarization state, the bandwidth thinning effect discussed previously could become more pronounced.

Dispersions

Finally, it is important to note that concurrent with deployment of ROADM- and WSS-based AONs is the initial roll-out of 40 Gbit/s systems. One particular challenge of 40 Gbit/s is the spread spectrum around the carrier. For example, a typical 40 Gbit/s non-return-to-zero (NRZ) signal fills a significant portion of the 100 GHz bandwidth channel. The criticality of this measurement has driven development of a new IEC standard IEC 61300-3-38. Group delay variation across the spectral bandwidth causes eye distortion and ultimately bit errors. The WSS test strategy must include the ability to upgrade by adding GD and DGD measurements. As described previously, bandwidth thinning is a reality in cascaded architectures. This GD variation becomes most pronounced at the edges. As the cascade number increases, GD variation can creep more prominently into the passband.

This new class of components forces a re-evaluation of test equipment and test strategies. Given the increase in test requirements, it is critical for test engineers to consider how to increase test capacity while keeping costs under control. Systems or instruments with a centralized distributed architecture allow multiple parallel tests to occur through distribution of the test signal to multiple measurement stations. Although one measurement station exists per module, the centralized test element is only purchased once. In addition, through the use of optical switching, multiple test devices can be connected to single measurement stations. This automation improves operational efficiently and capital utilization. Accuracy, speed, number of test cases, and strategies for reducing the cost of test are all critical components of emerging test plans (see "Key measurement requirements for WSS test equipment"). The JDSU SWS2000 has been designed with these key requirements in mind and can form the core of next-generation DWDM and WSS test strategies.

Matthew Adams is product line manager of Fiber Optic Production and Lab Test at JDSU, 61 Bill Leathem Drive, Ottawa, ON K2J 0P7, Canada; e-mail: [email protected]; www.jdsu.com.