Interest in optical nanofibers (loosely defined as fibers with outer diameters of 1 µm or less) is growing. Because they have such a small cross-sectional area, relatively large nanofibers can be used as nonlinear optical devices; even smaller nanofibers guide most of their light evanescently (outside of the actual fiber), making them useful for sensing.

Characterizing how nanofibers transmit light is important for both uses. Knowing the light intensity at the fiber center is essential for creating nonlinear devices; knowing the intensity at the fiber/air interface aids sensor design. A group at the Institute of Photonics Technology (Jena, Germany) has explicitly determined these parameters numerically as a function of fiber diameter, as well as clarifying other interesting characteristics, such as mode shapes and required fiber-taper lengths.1 The researchers also fabricated nanofibers to enable them to gather experimental data.

That taper needs to be how long?

Creating a nanofiber usually involves heating and drawing a section of larger-diameter fiber to create a section of nanofiber having a taper at one or both ends (depending on application). Knowledge essential for proper design includes not just the mode intensity profiles in and around the nanofiber but also the efficiency of the light transfer from the section of larger-diameter fiber through the taper and into the nanofiber. The researchers calculated this for various situations, based on a previously developed criterion.2

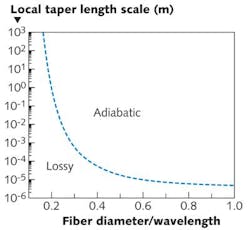

For a refractive index of 1.444 and a wavelength of 1550 nm, the researchers determined the taper length required for an adiabatic (lossless) transmission of light from a fiber with a standard diameter of 125 µm into a nanofiber (see figure). They phrased their results in terms of the ratio of the nanofiber diameter to the light wavelength (λ); as a consequence, the results are useful at other wavelengths as well.

For a diameter equal to 0.6λ or more, the taper length need only be 10 µm for adiabatic coupling, while for a diameter of 0.29λ, the taper should be about 1 mm long. For a diameter of 0.16λ, however, the required minimum taper length for true adiabatic coupling is an enormous 1 km.

Emergence of evanescence

Experimental transmission data were gathered continuously as a standard single-mode fiber was being drawn into a nanofiber. At the start, the 1550 nm laser light being transmitted was confined to the fiber core; as the outer diameter shrank to about 60 µm, the light escaped the core and the entire fiber became the "core." During further tapering, the transmission varied rapidly as the primary fiber mode alternated between two rotationally symmetric modes, HE11 and HE12. As the diameter became even smaller, the HE12 mode disappeared and the remaining HE11 gradually became a mainly evanescent mode. Finally, transmission dropped precipitously–one reason being that the taper length was much shorter than the lengths needed for adiabatic coupling into small fiber diameters.

The researchers did further numerical simulations to determine the mode characteristics as a function of the nanofiber diameter. For example, the fraction of optical power propagating outside the nanofiber as an evanescent wave is 18% for a diameter equal to 0.75λ but jumps to 97% for a diameter of 0.3λ. For diameters around 0.2λ and smaller, only very small imperfections in the fiber shape are sufficient to easily couple light out of the fiber (which, being irreversible, would be bad for sensing applications).

The maximum optical intensity value at the center of the fiber is reached at a diameter of 0.60λ–important in the design of nonlinear devices. The maximum intensity at the outer surface of the fiber is reached when the diameter is 0.44λ, allowing the light to interact well with gases, microparticles, or other substances outside of the fiber for sensing.

REFERENCES

- Alexander Hartung et al., Opt. Express 18, 3754 (2010).

- Y. Jung et al., Opt. Express 16, 14661 (2008).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.