PHOTOREFRACTIVE MATERIALS: Holographic telepresence approaches real-time operation

Three-dimensional holovision has been a stock prop of science fiction for decades (one famous example being the small image of Princess Leia projected by the robot R2-D2 in the first Star Wars film), yet efforts to develop a holographic successor to television have made little progress. Now Nasser Peyghambarian of the University of Arizona (Tucson, AZ) and colleagues have demonstrated a real holographic system that can transmit 3D images in near-real time between two points.1

Holographic movies can be projected by illuminating film containing a series of holograms, but real-time holovision poses a much tougher problem. Instead of projecting images from film made in advance, holovision requires a material that can display a series of holograms so it can project a series of holographic images. Developing a material on which holograms can be written and erased repeatedly at video frame rates has proved a daunting task.

Some optical tricks have been used to simulate holovision. Musion Systems Ltd. (London, England) has claimed to offer "holographic telepresence," although its system does not use holographic technology, but instead projects high-definition 2D images onto a semitransparent foil so that they look 3D to the audience. In another example, CNN's "holographic reporter" was based on a different illusion, the fusion of digital images.

A variety of materials has been tested for use as rewritable holograms, including liquid crystals and photorefractive materials, in which light induces a lasting change in the refractive index. Inorganic crystals show the photorefractive effect but are hard to make in reasonable sizes. Two years ago, Peyghambarian and colleagues showed that photorefractive polymers could be made in much larger sizes for updatable 3D holographic displays.2 To limit the amount of information that had to be transmitted to the display, they used holographic stereography, in which they took 2D photographs of an object from a number of different angles, then combined them into a hologram that showed three dimensions as the viewer's eyes looked from different angles. However, the system was monochrome, and needed more than four minutes to create a new image, hardly real time.

Two seconds per image

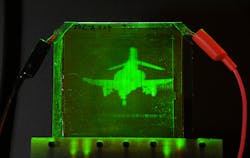

Now his group and researchers from Nitto Denko Technical Corp (Oceanside, CA) have built a laser system based on a new polymer. To speed writing, they replaced a continuous-wave frequency-doubled Nd:YAG laser with a doubled-neodymium system that emits 6 ns, 200 mJ pulses at a 50 Hz repetition rate. Each pulse writes an 800 μm stripe across a 10 × 10 cm piece of the polymer, producing a complete hologram in two seconds. Use of short pulses overcame vibration problems that plagued the earlier setup.

They also developed a new photorefractive material, a complex compound polymer, which they melted to form a 100 μm film between a pair of glass plates coated with conductive indium tin oxide electrodes that applied the 7 kV field needed to produce the photorefractive effect. Diffraction efficiency reaches about 70% almost instantly, peaks in about 25 s, then declines over several minutes in the dark. Writing a new hologram erases the old one.

Illuminating the hologram with an incoherent LED produces monochrome images. Color holograms can be displayed by writing three holograms at different angles, then illuminating them with separate red, green, and blue LEDs.

The new material "is a big step" beyond their earlier work because it's much faster and more sensitive, says Joseph Perry of Georgia Tech (Atlanta, GA). He's also impressed by the system engineering and integration, which uses 16 cameras to record one frame per second, which a computer processes into data for recording the hologram and transmits to the imaging system at less than 10 Mbit/s.

Commercial applications are seven to ten years away, Peyghambarian said at a press conference. Writing speed needs to increase from two seconds per image to 30 frames per second for video. Image size also needs to be increased; true real-time telepresence needs images 6 to 8 ft in size to show a human. He also hopes for better color, resolution, and sensitivity. But he notes that many applications for 3D imaging don't require full-video frame rates, such as medical imaging.

"We [have an image] about the size of Princess Leia," he told the press conference, so holographic telepresence "is no longer science fiction, it is something you can do today."

REFERENCES

1. P.A. Blanche et al., Nature, 468, 80-83 (Nov. 4, 2010).

2. S. Tay et al., Nature, 451 694-698 (2008).

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.