FORENSICS: Fingerprint analysis goes hyperspectral

ChemImage (Pittsburgh, PA), an analytical-imaging company, recently made improvements to its CONDOR Hyperspectral Imaging System that allow the system to see enhanced ridge detail in untreated latent fingerprints on paper.1Fingerprint analysis has long been a mainstay for law enforcement and forensic scientists when analyzing criminal evidence. Because most latent prints cannot be seen with the naked eye and often are only a fragment of a full fingerprint, analytical methods need to convert an invisible print to a visible one that can be viewed and reproduced for matching against a known database such as AFIS, the Automated Fingerprint Identification System maintained by the FBI.

Since early 2007, ChemImage has partnered with spectrometer and sensing-systems manufacturer Headwall Photonics (Fitchburg, MA) to develop spectrometer-based devices for ChemImage’s wide range of turnkey analytical instruments.2 For some products, Headwall supplies the OEM spectral-imaging engine to ChemImage.

Improved resolution, specificity

Latent fingerprints (those left on an object by touch, as opposed to fingerprints recorded by ink or other means) at a crime scene usually require some method to be visualized, such as the application of a powder or chemicals or reading by specialized imaging equipment. Hyperspectral imaging—the capture of hundreds of narrow spectral bands typically on a single detector, as opposed to multispectral, or the capture of several broadband channels on multiple detectors—can enhance the detection of latent fingerprints and improve specificity without physical contact or damage to the prints.

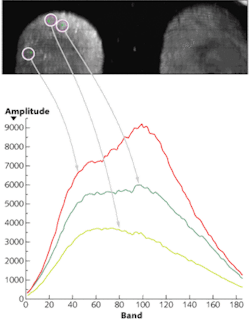

Hyperspectral imaging allows a forensic scientist to analyze and identify not only the fingerprint, but potentially any material left between the ridges of the fingerprint (see figure). For forensic applications, extensive chemical or spectral libraries are maintained for a wide range of material sets. “Headwall’s hyperspectral instruments are designed with aberration-corrected, all-reflective diffraction gratings and avoid the use of transmissive optics or prisms that tend to contribute to stray light and wavelength inaccuracy,” says Headwall CEO David Bannon. “In addition, by scanning through the hyperspectral data, an investigator is better able to view contrast differences from wavelength to wavelength that may help to identify specific ridge patterns of the fingerprint.”

The CONDOR Hyperspectral Imaging System applies these hyperspectral imaging techniques to reveal information that cannot be obtained using conventional techniques. Analysis can be performed on documents, body-fluid stains (blood, saliva, and semen), and both untreated and processed fingerprints. The system provides hyperspectral imaging from 410 to 1000 nm with a spectral resolution of 7 nm. The imaging field of view is approximately 250 × 250 mm or larger, if desired, with custom optics.

Liquid-crystal tunable filters are used to transmit a narrow passband of light through the filter onto the imaging camera (a CCD or EMCCD) where the intensity at a specific wavelength is measured for each pixel. The filters improve the spectral sensitivity to the print residue or the background, and the data- and image-processing software uses this hyperspectral information to remove or mute the background and draw out the contrast for a clearer image of the print. Once the hyperspectral image is obtained, the user can view the hypercube as a movie. The image changes as a result of changes in signal intensity from different materials in the image.

REFERENCES

- www.chemimage.com/docs/press-releases/CI_Press_Release_Improved_methods_for_latentprints.pdf (June 3, 2009).

- www.chemimage.com/docs/press-releases/ChemImage_Headwall_Anouncement_2-16-07.pdf (February 16, 2007).

Coming in September

Can Bayram and Manijeh Razeghi of Northwestern University’s Center for Quantum Devices explore development of a “best of both worlds” UV photodetector: a compact, semiconductor-based device capable of high sensitivity.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.