HIGH-POWER DIODE LASERS: Direct-diode lasers combine to form powerful, high-brightness beam

Multikilowatt laser-diode systems typically reach their high output powers through wavelength coupling of a number of individual diode stacks. While workable, this approach is a balance between wall-plug efficiency and beam quality. For example, a conventional multikilowatt fiber-delivered laser-diode system with an efficiency of about 40% will have a beam quality on the order of 100 mm-mrad—suitable for laser soldering or other surface processing. Improving the beam quality to 40 mm-mrad—which would allow such a laser to be used for deep welding—lowers the efficiency to about 32%.

To get around this limitation, engineers at Trumpf Laser (Schramberg, Germany) have developed a high-brightness fiber-coupled diode module that delivers 100 W at a numerical aperture of less than 0.12 from a fiber with a diameter of only 100 µm. Because the fiber diameter is so small, multiple fibers can be close-packed together to produce a much higher-power output, which can then be coupled into a delivery fiber. The company is commercializing the concept as the TruDiode direct-diode laser series.

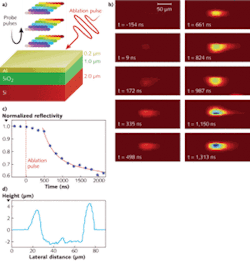

The outputs from up to 19 modules are combined into a single output fiber, so that a laser output of up to 1900 W can be achieved from one unit. The number N of the fibers determines the diameter of the output and the final beam quality (see figure).

While the individual modules have a beam quality of about 5 mm-mrad, the beam quality of a unit consisting of 19 combined modules is about 25 mm-mrad. The significant advantage of the new technology is that the efficiency of the individual diode modules is maintained and values of more than 40% for the integrated system can be achieved.

Higher output powers can be reached by the coupling of multiple wavelengths. When two wavelengths are coupled, the output can be as high as 3800 W; coupling three wavelengths can produce 5700 W. The TruDiode units have outputs from 1 to 4 kW.

The coupled wavelengths lie close together to minimize problems such as more-complicated designs for optical coatings and protective glasses, as well as optical-dispersion-introduced spreading of the beam foci in the z direction; the latter is especially important, as the engineers needed to ensure that the new direct-diode lasers could directly replace earlier optically pumped systems without introducing disadvantages such as smaller working distances, larger focused-spot diameters, or larger optics.

High efficiency lowers costs

Existing leading-edge technologies such as disk and fiber lasers rely on laser diodes to pump a medium and transform the radiation to a longer wavelength and improved beam quality, losing roughly up to 40% of the power and efficiency in the process. The absence of this step in the TruDiode direct-diode laser systems reduces electricity costs considerably, and allows the use of passively cooled diodes. The service life of the diodes is extended to the point that they are no longer a “consumable,” which avoids the expense of exchanging diodes—and the larger cost of having to shut down manufacturing operations for the exchange.

The future will see further improvements in brightness, says David Havrilla, Trumpf’s high-power-lasers product manager. This will open up applications in remote scanner welding, as well as deep penetration and hybrid welding (see www.laserfocusworld.com/articles/341584). As for wavelength combination, “at the moment we see four wavelengths as appropriate for our use, but in principle the technique could be extended to five, six, or seven wavelengths—though we do not foresee a need for this number of wavelengths,” says Havrilla.

“In the future,” he adds, “the debate regarding fiber versus disk lasers will take a dramatic turn, and the focus will turn to direct-diode lasers.”

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.