HIGH-POWER SOLID-STATE LASERS: The Mercury laser moves toward practical laser fusion

CHRIS EBBERS, JOHN CAIRD, and EDWARD MOSES

The National Ignition Facility (NIF) at Lawrence Livermore National Laboratory is on target to demonstrate “breakeven”—creating as much fusion-energy output as laser-energy input. The NIF laser will compress a tiny sphere of hydrogen isotopes with 1.8 MJ of light in a 20 ns pulse, packing the isotopes so tightly that they fuse together, producing helium nuclei and releasing energy in the form of energetic particles. The achievement of breakeven will culminate an enormous effort by thousands of scientists and engineers, not only at Livermore but around the world, during the past several decades.

But what about the day after NIF achieves breakeven? The National Ignition Facility is well suited for engineering research, but if laser fusion is ever to generate power for civilian consumption, the laser will have to deliver pulses nearly 100,000 times faster than NIF—a rate of perhaps 10 shots per second as opposed to NIF’s several shots a day.

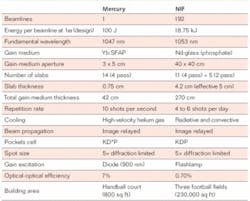

The Mercury laser (named after the Roman messenger god) is intended to lead the way to a 10-shots-per-second, electrically efficient driver laser for commercial laser fusion. While the Mercury laser will generate only a small fraction (1/30,000) of the peak power of NIF, it operates at a higher average power. The design of Mercury takes full advantage of the technology advances manifest in its behemoth cousin (see table).One significant difference is that, unlike the flashlamp-pumped NIF, Mercury is pumped by highly efficient laser diodes. Mercury is a prototype laser capable of scaling in aperture and energy to a NIF-like beamline with greater electrical efficiency, while still running at a repetition rate 100,000 times greater. While the goal of NIF is to achieve fusion breakeven, the goal of the Mercury laser system is the demonstration of a reliable diode-pumped solid-state laser system capable of scaling in aperture to the equivalent energy of a single one of NIF’s 192 beamlines. Diode pumping reduces the heat deposited into the Mercury laser, while gas cooling allows the residual heat to be efficiently removed.

System design

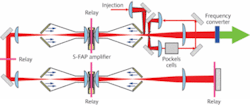

Mercury is seeded by a precision fiber-based laser (see Fig. 1). This seed pulse is amplified in the preamplifier to an energy of 0.5 J and injected toward the first amplifier. The pulse passes through the first and second amplifiers and is reflected back through both, and then sent back for a third and fourth pass through the amplifiers to provide optimum energy extraction. After being amplified to its maximum energy, the pulse is directed toward the frequency converter. To date, Mercury has operated for more than 300,000 shots at greater than 50 J at a repetition rate of 10 shots per second. Ultimately, Mercury’s goal is to generate 100 J pulses at this rate.

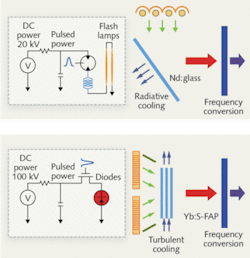

The pumping geometry in Mercury is different from NIF’s (see Fig. 2). Using laser diodes to pump Mercury enables an order-of-magnitude increase in electrical efficiency compared to NIF. Each of Mercury’s two amplifiers is pumped by four 80 kW laser-diode arrays. The diode light is first angularly redistributed by hollow concentrating optics to a 3 × 5 cm2 aperture in which the angular divergence of the beam is made nearly identical in both the x and y axes. The diode light is then guided by a rectangular reflective cavity, which maintains the angular distribution while smoothing the spatial profile.The amplifiers are face-cooled with high-pressure helium gas, removing approximately 3 W/cm2 of heat with minimal thermal wavefront distortions. Helium is chosen for two unique properties: its low refractive index and its high thermal conductivity. One advantage of gas cooling is that the technology is scalable—once a system design has been formulated to remove a certain amount of heat per square centimeter, it is possible to scale in aperture, allowing a small-energy (100 J) laser system to operate with the same characteristics as a large-aperture system with 100 times more energy. This heat-removal method is applicable not only to the laser gain medium, but also to the frequency-conversion system, in which the IR laser emission is converted to green or UV light.

Selection of gain material

The design of a complex laser facility is driven by multiple, sometimes conflicting, issues. Here, we’ll concentrate on three issues involving the selection of gain material, because that selection has the most direct impact on efficiency, cost, and durability. These issues are: quantum defect, upper-lasing-level lifetime, and emission cross section. Essentially, these can be translated to the amount of energy (heat) left in the laser gain medium after efficient lasing, the number of diode pump lasers required to effectively provide the gain, and the amount of laser light (fluence) needed to circulate through the laser gain medium to efficiently extract the stored energy.

The quantum defect is important because it determines the amount of waste heat that must be removed from the gain medium. We selected crystalline strontium fluoro-apatite doped with ytterbium (Yb:S-FAP) as the gain medium for Mercury. The ytterbium dopant absorbs diode light near 900 nm and emits near 1047 nm, indicating a quantum defect of 15%. In other words, an absolute minimum of 15% of the pump energy must be removed as waste heat.

The upper-state lifetime is important because it directly affects the number of diode-laser pumps required to achieve a given energy output from the laser. The longer the upper-state lifetime, the longer the diodes have to pump the necessary energy into the population inversion. To achieve a 100 J output with its 15% quantum efficiency, Mercury must pump at least 115 J into its amplifiers’ population inversions. Yb:S-FAP has an upper-state lifetime of 1.1 ms, which means it must be pumped with more than 100 kW of diode light. By comparison, if NIF’s Nd:phosphate glass were Mercury’s gain material, its 360 µs lifetime would require three times as many diodes.

Finally, the emission cross section is important because it determines the gain medium’s saturation fluence—the energy fluence needed to extract 63% of the stored energy in a single pulse. Gain materials with a low saturation fluence, like Nd:YAG, whose saturation fluence is 0.62 J/cm2, are not well suited for large-aperture, high-energy laser systems. In a large-aperture Nd:YAG system, small amounts of spontaneously emitted energy moving sideways across the aperture can build quickly, depleting the gain available for the main pulse. Nd:phosphate glass has a saturation fluence of 4 J/cm2, so large-aperture systems experience manageable losses from amplified spontaneous emission. With a saturation fluence of 3 J/cm2, Yb:S-FAP is much closer to Nd:glass than Nd:YAG.

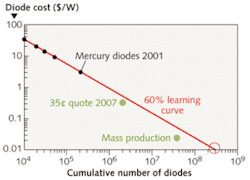

The saturation fluence is one example of how lasing efficiency drives an aspect of the laser design. A high saturation fluence (well above that of Nd:glass) can store tremendous amounts of energy per beamline, but requires a high laser fluence (possibly high enough to cause optical damage) to extract the energy. In contrast, a low saturation fluence leads to many beamlines. It is likely that a contemporary facility will use a material with a saturation fluence similar to that of Nd:glass, using the tremendous advances in beamline design, fabrication methods, and optical-reliability data to fullest advantage. The Mercury laser system uses this developed expertise. Yb:S-FAP was chosen for its similarity to Nd:glass in many aspects (except availability). The combination of long lifetime, moderate drive fluence and aperture scaling, and, especially, the lower energy defect, drove the choices from the viewpoint of reducing the cost of diodes required for a 100-J-class laser. If diode costs continue to drop, at some point the need to select a material based on long lifetime will become less important.

The price of diodes will play a major role in the commercialization possibilities of laser-driven fusion energy. Diode lasers are currently expensive: in 2001, the diodes for the Mercury laser system were priced at roughly $1.60 per peak watt of output power, excluding the cost of the power supply. However, diode lasers are on an aggressive “learning curve” (see Fig. 3). With increasing production, diodes will continue to drop in price from dollars per watt to pennies per watt.Automatic control

A hidden but critical aspect of a laser facility is the control system. Like NIF, Mercury depends on a system of remote alignment and inspection diagnostics. Critical beam optics are continuously monitored. If optical damage occurs during one shot in a high-repetition-rate system, it is impossible to shut down the system manually before the next shot causes further damage. Instead, an automatic system compares data from the previous laser shot to the current laser shot. Any significant differences are flagged, allowing the system to be safely stopped before the next shot, preventing potential damage to more than a single optic. Such a data collection and analysis system will be the real brains behind a potential multiple-beamline power-generating system running at a high repetition rate, allowing a safe shutdown and refurbishment of any optical components, as needed.

ACKNOWLEDGMENT

This work is being performed under the auspices of the U.S. Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344.

Chris Ebbers is Mercury Laser project manager; John Caird is program element leader, Fusion Energy Systems; and Edward Moses is principal associate director, NIF & Photon Science Directorate at Lawrence Livermore National Laboratory, P.O. Box 808, Livermore, CA 94551-0808, e-mail [email protected]; www.llnl.gov.