DIFFRACTIVE OPTICS: Harmonic optical element simplifies Blu-ray optics

A harmonic optical element added behind the objective lens of a Blu-ray pickup allows it to handle Blu-ray, DVD, and CD wavelengths with a single optical system.

Adam Fedor

Blu-ray is a relatively new format for optical storage that provides higher capacity than DVD. The standards for 12 cm Blu-ray rewritable discs were established in 2002–the discs provide up to two hours of high-definition content with a single-layer recording capacity of 25 GByte. Because this device was intended for the highly competitive consumer market, it needed to be backward compatible with standard DVD and CD media.

The fundamental challenge to achieving higher-density storage compared to a standard DVD is to realize a smaller beam spot size. This means using a shorter (blue) wavelength with a higher-numerical-aperture (NA) objective.

One might think that it would be possible to use a single blue laser to read all three formats, but the damage characteristics of the materials used in DVD and CD media prevent the use of a blue device. Hence, three lasers with wavelengths of 780, 660, and 405 nm, respectively, are required along with optical systems to support them. This increases the cost, as the pickup unit must contain these three optical systems.

A major cost savings can come from running all the lasers through a single optical path. However, due to material dispersion, the objective lens and conventional components in the optical path can only provide the necessary diffraction-limited performance at one wavelength.

Single pickup lens

To circumvent this problem and allow a single Blu-ray objective lens to handle multiple wavelengths, a harmonic optical element (HOE) can be added to the optical system. A harmonic optical element is a diffractive optical element in which the depths of the features are multiples of the design wavelength (a harmonic optical element should not be confused with a holographic optical element, which has the same acronym and is also a type of diffractive optical element).

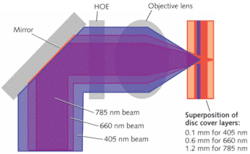

For the Blu-ray design, the HOE is a diffractive optic that has been designed for operation at three different wavelengths. The HOE is paired with an optimized objective lens designed to work in a Blu-ray read/write device having backward compatibility with DVDs and CDs in a single optical path.

The system is designed so that at the blue (405 nm) wavelength, light passes without modification through the HOE and is focused to a diffraction-limited spot at the correct distance by the objective lens for Blu-ray discs (see Fig. 1). The HOE functions to impose a separate phase function at 660 nm and another at 785 nm, such that the proper focal length and diffraction-limited performance is achieved for DVD and CD media as well. The challenge is to construct an HOE that can work properly at each of the three different wavelengths without the independent phase functions causing interference at the other wavelengths.

HOE/OL interactions

Conventional wisdom would suggest that the objective lens should be initially optimized for the 405 nm wavelength, and the 660 nm and 785 nm wavefront correction encoded in the HOE. Using this approach, spot size and root-mean-square (rms) wavefront specifications are readily met over the required fabrication and assembly tolerances, and performance over the full wavelength range is good. However, the resulting HOE design is very inefficient.

A sensitivity study on the harmonic design efficiency suggests that small variations in the 660 and 785 nm wavefront correction can yield substantial changes in the efficiency of the harmonic element, while still maintaining high performance over the assembly tolerances. It is apparent that optimized HOE efficiency can be improved or degraded significantly by small changes in the objective-lens design. Exploiting these interactions proves to be the key to designing a superior pickup lens system.

Simultaneous optimization of the objective lens and the HOE, however, creates a fundamentally difficult problem. The 0.85 NA objective lens is modeled using a commercially available ray-trace design package. The harmonic element is effectively simulated using a physical-optics propagation algorithm coupled with a simulated-annealing optimization engine. The two programs are profoundly incompatible.

To solve the problem in the quickest manner, we perform a parameter study of the solution space around our nominal objective-lens design, and determine the first-order changes in the 785 and 660 nm wavefront correction that can be tolerated without compromising the pickup-lens system performance. This gives us a matrix of possible phase functions that can now be used as design variables in the optimization of the HOE encoding. In the future, it should be possible to couple the ray-trace and HOE optimization packages to make this type of design a true system optimization.

HOE encoding

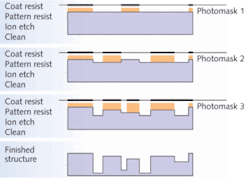

In a typical HOE design, the ideal continuous phase function is approximated by a quantized version of that function. For the Blu-ray HOE, we want to choose phase levels to approximate the desired phase function (IR, red, and blue) at all three wavelengths simultaneously. The blue light is to be nominally uncorrected, and the red and IR light should experience a phase shift, which corrects for the chromatic aberrations of the objective lens. In the lithographic method, glass or some other material is removed in a step-wise manner to provide a specific phase delay corresponding to the desired phase of the lens function (see Fig. 2). Ideally, one would choose a phase delay that gives the proper phase change for the IR, red, and blue lens functions simultaneously.

null

This is a difficult problem, as the wavelength of the IR laser is nearly twice that of the blue laser when the dispersion of typical glasses is factored in. The design of a harmonic element in fused silica provides a ready example. A structure etched to the first blue harmonic depth in fused silica introduces a phase lag of 6.283 (2∏) radians at 405 nm and 3.13 (approximately ∏) radians at 785 nm. This makes it nearly impossible to encode an IR corrector element with high efficiency in conventional glass, as any HOE that channels the blue laser into the zero-order (uncorrected) beam would channel the IR laser into a corrected beam with efficiency of about 40% or less. There are two ways to avoid this: increase the phase depth of the HOE to naturally enhance the small difference in refractive indices; or choose a material with a larger dispersion between blue and IR.

Increasing the phase depth of the harmonic structure produces more degrees of freedom–in this case, the deeper levels tend to help increase the small difference in phase created by the refractive-index differential between blue and IR. However, there are practical as well as design reasons why one would not want to increase the phase depth of the harmonic structure too much. Practically speaking, deeper structures are harder to manufacture and are significantly more sensitive to fabrication errors, including etch-depth errors and nonperpendicular sidewalls. Even with the best fabrication methods available, there are also design constraints that limit the practical depth of the harmonic corrector. Specifically, deeper correctors tend to be more sensitive to wavelength changes. With a deep harmonic structure, even a few nanometers of change in the blue laser wavelength can easily throw the efficiency well out of spec.

System optimization

As a result of these problems, we use an optimization process that finds the best balance between the phase delay at IR, red, and blue wavelengths to give the best approximation to the correct lens function.

The optimization process consists of a beam-propagation model set up to look at the output of the complete HOE/OL system. A feedback loop is instituted to adjust the phase levels of the HOE to achieve the highest efficiency at all three wavelengths. In this way, direct measurement of the system’s efficiency is used as the metric to identify the best design, and it is easy to include any number of desirable constraints, such as wavelength sensitivity and fabrication limits.

Material effects

One interesting question that this brings up is: “What is the ideal material for fabricating the HOE?” We can answer this question by doing the same type of HOE optimization described previously, but in addition to varying the depth and/or phase levels of the structure, we vary the index of the substrate material (within a normal range for realistic materials). We find that in most cases it is the dispersion of the material that is most critical rather than the absolute refractive index of the material. Typically, a 1% to 2% difference between the blue and red refractive indices and a 2% to 3% difference between the blue and IR refractive indices works the best.

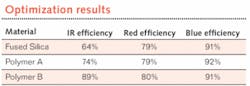

To take advantage of these results, we can look at a number of different materials as possible substrates for the harmonic-corrector element. For this project, we found several materials that meet the required dispersion criteria and are also readily available and easy to work with. Our optimization results show that fused silica performs the worst because it does not have good dispersion characteristics (see table). Polymer A is a widely used off-the-shelf polymer. Polymer B is a new material developed specifically with the desired dispersion characteristics for this application.

Using a parameter study and propagation-based optimization process, we were able to design a single-optical-path read/write objective lens for Blu-ray, with reverse compatibility to work with both DVD and CD media. The HOE simulated efficiency was between 64% and 90% efficiency in the IR and red wavelengths and more than 90% efficiency in blue wavelengths (depending on the material used). The use of this design approach is not limited to harmonic elements needed for data storage applications; other applications that require harmonic correctors can also benefit. Military and communications applications could see improvements in system performance by using similar methods in harmonic-element design.

Adam Fedor is principal optical engineer at Tessera, 3025 Orchard Parkway, San Jose, CA 95134; e-mail: [email protected]; www.tessera.com.

Tell us what you think about this article. Send an e-mail to [email protected].