Vibration Isolation: Effective vibration reduction stabilizes laser beams

JAMES FISHER AND VYACHESLAV M. RYABOY

Optical tables and vibration isolation supports have become the de facto standard for providing a stable environment for complex laser systems and their applications. Such systems are becoming increasingly complex as they are expected to deliver more resolution and information than ever before. However, all components in a setup must be considered—even the most elegant vibration-isolation solution can be rendered useless if it is not installed properly.

Above all other qualities, the single most important benefit that must be delivered by any optical table is dynamic rigidity. In any laser application, beam stability is primarily affected by table compliance that results in point-to-point relative motion changes along the length of the table. This motion can be caused by many different sources of vibration including table-mounted devices, as well as HVAC systems and other acoustic sources. The best way to reduce these vibrations is to eliminate them at the source using baffles on air ducts, compliant pads under instruments, or acoustic enclosures. It is important to note that while optical tables provide stabilized platforms for optical experiments they do not entirely eliminate tabletop vibrations from reaching other components on the table surface that can contribute to beam stability.

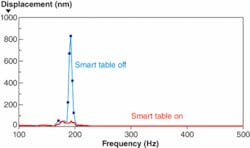

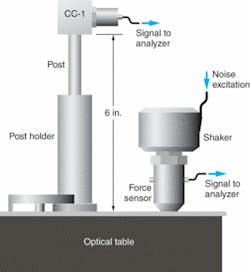

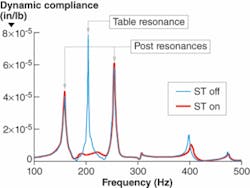

Optical-component deflection is the second largest constituent of vibration noise in most optical systems. Even in environments where the optical table is acting as a rigid body, this rigid-body motion can still excite natural vibration of optical mounts and cause beam instability. To demonstrate the magnitude of movement that can be experienced by an optical mount in a typical lab environment, we mounted a 1-in.-diameter optical mount on a 6 in. post to simulate a typical optical setup (see Fig. 1). We then introduced broadband noise to the table surface, similar to that of a table-mounted fan or motorized stage or similar acoustic disturbance. To measure the movement of the mount we used a laser vibrometer that does not introduce any mass-loading effects. And, to understand the influence that optical-table damping might have in reducing these motions, we used a SmartTable optical table with active damping to measure both the structurally damped and actively damped motions.

Active table damping

The ST Series SmartTable optical table implements active vibration damping by using vibration sensors and actuators embedded in the tabletop structure, as well as control electronics and sophisticated algorithms (see www.laserfocusworld.com/articles/279854).1 Besides the ability to control and monitor vibration of the tabletop, the SmartTable provides a unique testbed for experiments elucidating the role of table damping versus component damping in optomechanical systems.

For the 1-in.-diameter optical mount on a 6 in. post, the optical mount can experience 800 nm of movement under excitation. But with the use of the SmartTable and active damping, this movement was reduced to between 10 and 20 nm. In this experiment, the natural vibration frequency of the post and the optical mount was close to the natural vibration frequency of the tabletop, which explains high amplitude of vibration and drastic effect of table damping. While all optical components exhibit varying natural frequencies, this data does suggest that optical-component selection, installation, and the tabletop environment should be considered together to optimize beam stability.These experiments not only demonstrate the performance improvement achieved with an actively damped table but also verify that optical component vibrations are a contributing factor to beam stability. Several approaches can reduce these motions: minimize optical-axis heights whenever possible, use the most robust posts and clamps available for your sensitive optics, and place these sensitive components as close to the center of the table as possible where table compliance is typically the lowest. If it is necessary to arrange a higher optical axis, large-diameter damped optical rods should be used.

Microscopy applications

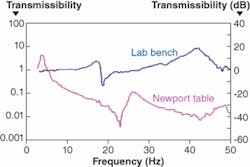

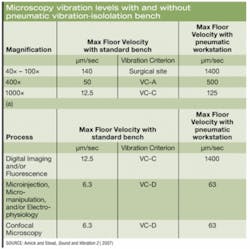

Every piece of equipment on an optical table has its own natural frequency, and is, therefore, vulnerable to vibration excitation in its own particular frequency range. Hal Amick of Colin Gordon and Associates (San Bruno, CA), a vibration solutions company, and Matthew Stead of acoustic design consultants Bassett Acoustics (Melbourne, Australia) conducted a thorough research of vibration sensitivity of microscopes at various levels of amplification and for various applications. They found that natural frequencies of microscopes are typically, between 13 and 50 Hz. Fortunately, state-of-the-art vibration isolation systems can effectively filter out vibrations in this range.In addition to the high-frequency components that affect tabletop rigidity and component stability, users should also be aware of lower-frequency disturbances that can affect system performance, particularly when they are near the resonant frequencies of the system components. Pneumatic isolation systems have typically been used to provide effective reduction of floor vibrations from reaching table surfaces and exciting the resonant modes of the table and other components but their effectiveness in reducing lower-frequency disturbances should not be discounted. Choosing the appropriate vibration-reduction equipment requires not only an understanding of the lab environment but also an awareness of the sources of tabletop noise and the sensitivity of the other table-mounted components.

The final step in putting together an effective vibration-control system is to consider installation issues that could render any elegant product solution useless. It is important to review all installation aspects with your facilities personnel before making a final purchase decision.

Installing a system

It is extremely important to verify that the required vibration-control system(s) can be taken to and installed in the lab space. Walk through your installation route with your facilities team, colleagues, or riggers—receiving dock, elevator, hallways, doorways, and possibly windows if a crane will be used—so that any logistic issues are addressed and final product selections can be changed if necessary.

Next, verify that your lab has the necessary utilities for the vibration-control system. This includes regulated voltage and maximum current requirements, adequate lighting, a dry air supply for pneumatic isolation systems, and ventilation/climate control to maintain the required temperature in the lab. If the location does not have clean/dry air, a high-quality air compressor should be used to supply any pneumatic isolators. Dirty or wet air lines can significantly reduce the performance of pneumatic isolation systems and unregulated power can introduce unwanted noise and/or power surges into sensitive electronic equipment.

And finally, use the right tools for the job. The installation of an optical-table system should never involve a dozen people lifting the table while several others move the supports into location. Installation of large tables is best left to experienced professionals who have the tools, experience, and proper insurance to install the system safely. Laboratories in seismic risk zones should also have the proper seismic restraints on all system components to comply with current building codes.

Although modern vibration-control systems can provide drastic improvement to vibration stability of optoelectronic applications, they are not panaceas or magic wands. To achieve good results, pay attention to the vibration environment and reduce acoustical impact, remove unnecessary sources of vibration from the isolated platform and immediate vicinity, and make sure the isolation system is properly installed and not shunted by stiff cables. Finally, the beam stability of a tabletop laser system is defined by dynamic properties of the whole vibration-transmitting “structural loop,” which includes support structures, optomechanical elements, optics, and motion-control systems.

REFERENCE

1. J. Fisher and V.M. Ryaboy, “Next Generation auto-tuned optical tables,” Photonics Spectra (June 2005).

Editor’s note: For a video description of the SmartTable, see www.laserfocusworld.com/resourcecenter/video.html

JAMES FISHER is the group director and VYACHESLAV M. RYABOY is the principal engineer for the Vibration Control Product Group at Newport, 1791 Deere Ave., Irvine, CA 92606; e-mail: [email protected]; www.newport.com.