Optical coatings: Rugate coatings enhance performance of head-up displays

JOHN ALLEN

A head-up display (HUD) provides the ability to project information onto a transparent screen so that it appears to be floating in space as a virtual image. With suitable optics, the virtual image is combined with the view of the real world seen through the screen so that both images appear to be at the same distance. In this case, the screen is known as a combiner. When used in aircraft, HUDs enable the pilot to see flight information without having to refocus on flight instruments. Other applications such as automotive windshields now also use such technology.

To obtain sufficient reflection, the glass combiner has a neutral-color, thin-film interference coating, which increases the reflectivity to 23% and in turn reduces the visible transmission through the combiner to 77%. The transmitted view is color-neutral while the virtual display image derived from the cathode-ray tube (CRT) is green, where the human eye is most sensitive.

Because of advances in light engines and display technologies using light-emitting diodes (LEDs) and lasers, these displays are now finding their way into new applications. These sources can generate very bright images in several colors, spurring the transition from monochromatic to multiple-color displays. We have developed high-performance optical thin films based on multiple reflective-notch rugate coatings for the HUD screen, which appear neutral in color, but provide high reflection efficiency of individual colors while maintaining clarity of view to the outside scene.

Monochromatic displays

To work effectively, information from the virtual image in head-up displays must be visible in a variety of conditions. In aircraft, the display must be sufficiently visible to contrast with the background sky in bright cloud or sunlight conditions. The advent of near-monochromatic green phosphors in CRTs such as P53 has led to the development of HUDs with increased display brightness. This enables the use of narrow-bandwidth reflective notch filters, with a peak reflection centered at the same wavelength as the phosphor primary peak. Because the filters reflect only a narrow portion of the visible spectrum, they transmit most of the outside world spectrum and lose only a narrow portion of the green spectrum. Rugate filter technology is a powerful and efficient method for generating color-selective reflection coatings for HUD combiners.

Rugate filter technology is also a powerful design tool in thin films. Whereas conventional optical thin-film coatings use discrete layers of different materials to modify the reflection of glass surfaces, rugate technology acts like a single inhomogeneous film with a refractive index that varies continuously and periodically throughout the thin-film structure. The term rugate derives from the periodic way that the refractive index varies within the film. Rugates can extend the design possibilities of thin-film coatings to include properties not readily available with conventional thin-film designs. One such area is the design and manufacture of narrow-bandwidth reflectors. A sinusoidal refractive-index profile produces a single reflection band (or “notch”) whose bandwidth is a function of the refractive-index extrema, and whose reflection is a function of the number of cycles.

Modification of the refractive-index envelope in a controlled way can make the spectral transmission virtually free of ripples, maximizing transmission at all wavelengths other than the narrow-bandwidth reflection notch. This gives the designer freedom to tailor the design for any configuration. It is possible, for instance, to change the performance progressively across the combiner surface to compensate for changes in angle of incidence, ensuring that the brightness of the virtual image is constant for different viewing positions.

Rugate technology is therefore well suited to HUD combiners because it is much more efficient in both transmission and reflection than a conventional neutral-combiner coating. A monochromatic green display can achieve greater than 80% photopically weighted transmission through the combiner, while maintaining up to 80% reflection of the display.

A digitization process converts a theoretical rugate design into a manufacturing recipe, creating many thin-film layers from a continuous refractive-index profile. The digitization is a compromise between spectral resolution, freedom from harmonics, and manufacturing process control. We have manufactured several rugate combiners that have been evaluated in avionic cockpits for several programs. The thin-film coatings are fabricated in a high-precision vacuum-coating system with plasma-assisted deposition to ensure that the coatings are insensitive to temperature and humidity variations, and that they meet the required military environmental performance. One version, using a green-laser source as the light engine, has achieved measured performance in excess of 82% visible transmission while simultaneously maintaining an eye-response display reflectivity greater than 80% over the field of view.

Today, many transport and civilian aircraft cockpits make use of rugate HUDs. An HUD onboard the flight deck of commercial aircraft enhances the flight takeoff and landing envelope in poor weather conditions and airstrips without instrument landing systems. In such aircraft, the HUD configuration is usually a single-plate combiner that can be stowed when not in use. The display is projected onto the combiner from behind and above the pilot, the combining element often forming part of the optical collimating optics. Rugate technology can help improve this HUD performance by tailoring the spectral properties of the rugate coating across the surface of the combiner, producing an extremely uniform display, and a bright and unimpaired view of the outside world with minimal coloration (see Fig. 1).

Color HUDs

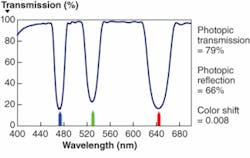

The development of multiple-color light engines has opened up the possibility of developing color head-up displays. The automotive industry has already deployed color HUDs in several upmarket automobiles as a driving aid. The automotive HUD reflects the display from the windshield, producing a virtual image in front of the driver. In direct sunlight, the light engine has a challenging task in supplying a viewable image display (see Fig. 2).The flexibility of rugate technology opens up the possibility of multiple reflective-notch combiners for use in full-color HUDs. By superimposing different refractive-index profiles in parallel, it is possible to design rugates with multiple reflection notches, in which the wavelength and reflectivity of each notch is independently varied to match the display color output. Again, modifying the refractive-index envelope profile maximizes transmission at all wavelengths outside the reflection bands. We have designed and manufactured triple-notch rugate combiners in which the reflection notches coincide with the emission wavelengths of blue, green, and red LED sources. In this case, independent adjustment of the wavelengths and notch depths balances the light output to the eye, resulting in a combiner that is neutral in color, with an extremely bright three-color display.

The typical measured photopic transmission of a curved combiner is 79%. Multiple-notch rugate combiners are ideal for applications in which image brightness coupled with clear visibility through the combiner is of paramount importance (see Fig. 3).Rugate dual-graded combiners

In fighter aircraft where space is limited, most military HUDs use two combiner plates at an inclined angle, parallel to each other but separated vertically. The virtual image is therefore “shared” between the upper and lower combiner. In this configuration, the pilot’s view of the outside world must be clear, with no discontinuities that might be interpreted as an artificial horizon. To facilitate this illusion, the combiners overlap each other, and the reflection of each combiner plate is progressively reduced (or feathered) to make the transition smooth and the combiner edges almost invisible. The overlap region in the dual combiner assembly is called the “grade.”

In conventional neutral-graded combiners, progressively reducing the thickness of the thin film facilitates the change in reflection. Although this process also changes the image color, the spectral bandwidth is so wide that the color change is not pronounced. In the case of rugate notches, progressive reduction of the reflection-notch depth without wavelength change is necessary. So the notch-combiner coating is a large series of rugate filters at different positions on the combiner with the same optical thickness but different depths of reflection. The rugate filter effectively converts progressively from a reflection notch at one end of the combiner to an antireflection coating at the other end of the overlap.

Dual-graded rugate combiners for fighter aircraft programs show good performance with greater than 80% visible transmission while providing 40% display reflection. An additional feature of these combiners is that the narrow width of the reflective rugate notch minimizes unwanted solar reflections.

Further developments

Because weight and safety are of paramount importance for avionics, the possibility of plastic combiners are of considerable interest. Single-notch rugate filters on polycarbonate visors for helmet-mounted displays are under evaluation in several military programs. Other programs may extend this capability to multiple-notch coatings for visors and plastic combiners for head-mounted displays. The techniques developed will enable even more-complex rugate coatings to be manufactured on plastic substrates.

For future applications, dual-graded combiners for three-color displays could have triple-notch graded rugate coatings in which the notch depth progressively decreases over the grade to become an antireflection coating. In fighter aircraft, a multiple-color display would enable warning indicators to attract attention sooner than a monochromatic display. Interest in full-color HUDs is already high, so it is likely that future avionic programs will incorporate narrow-bandwidth color light engines and multiple-notch combiners.

JOHN ALLEN is technical director at AFE Technology Coatings, 1 Drakes Court, Eagle Road, Langage Business Park, Plympton, Plymouth, England PL7 5JY; e-mail: [email protected]; www.afetc.com.