NANO-OPTICAL FABRICATION: Devices mimic fruit-fly eyes and butterfly wings

A technique for making physically robust nanoscale optical components—precisely modeled on physiological structures of insects—has enabled researchers at Pennsylvania State University (Penn State; University Park, PA) to “pull the wings off of flies and butterflies,” so to speak, in the form of chalcogenide glass replicas. The researchers expect their new technique to enable fabrication of (among many other things) novel optical-sensing and transmission devices with numerous industrial, medical, and security applications.1, 2

“We were motivated by the simple fact that many structures have evolved in nature to display interesting and useful properties,” said Akhlesh Lakhtakia, who collaborated with Raúl Martín-Palma and Carlo Pantano to develop the technique. “The most appealing of these properties are optical, imparting either coloration and/or camouflage to the organism, and optical-imaging structures such as compound eyes or polarization-sensitive eyes are also attractive. If we could easily replicate these and other attractive features, we could exploit them for various techno-scientific purposes.”

For instance, the development of miniature cameras and optical sensors based on the compound eyes of flies could enable integration of such devices into tight spaces in automotive applications, credit cards, displays, security and surveillance applications, and medical-imaging technology. Because the compound eyes of flies are also very efficient collectors of light with a unique optical scheme for imaging and very wide fields of view, fly-eye replicas might also be used to fabricate solar-cell covers and other energy-harvesting structures, as well as lenses with outstanding spatial resolution.

Replicas of such biological structures, created in robust and infrared transparent materials such as chalcogenide glasses, might also enable development of infrared microlenses and infrared sensors hardened to visible laser radiation. Potential photodiode applications might also include horizon sensors for satellite orientation systems and solar tracking systems for solar cells.

Difficult to mimic

Traditional physico-chemical methods cannot be effectively used for the replication of nanoscale and nonplanar features generally found on biological structures, according to the Penn State researchers. The nanoscale and nonplanar features of biological structures pose significant problems. Additionally, the need for caustic chemicals or high temperatures, or both, usually precludes the use of biological templates, according to Martín-Palma.

The Penn State research team addressed these problems by developing a variation on the oblique angle deposition (OAD) technique, which essentially involves directing a vapor flux towards a substrate, with a trajectory that is oblique to the substrate normal. A major advantage of the OAD technique for working with organic or biomaterials is that it does not require high temperatures or pressures. Many organic materials will decompose when the temperature goes significantly above room temperature, and the Penn State researchers didn’t want any organic transformations to take place during the deposition process.

Ultimately their goal of fabricating a high-fidelity replica required adjusting the deposition parameters and choosing the deposition geometry. They achieved it primarily by rotating the biotemplate substrates rapidly (typi cally, between 0.5 and 2 revolutions per second) during the OAD process, which enabled them to make high-fidelity replicas with relatively substantive and robust materials. The resultant technique, which they dubbed conformal evaporated-film-by-rotation, enabled them to replicate the curved and compound eye as well as the delicate wings of a tephritid fly (common fruit fly) in chalcogenide glass with nanoscale precision.

“We set out to produce a high-fidelity replica of the original biotemplate, in this case, the eye. And we were able to cover in very fine detail, with very fine features, not only the fly’s eye, but the entire fly’s head,” Lakhtakia said. With the butterfly wing they were able to faithfully replicate, not only the periodic scales (30 to 40 µm in diameter) that make up the wing, but also the nanoscale reticular patterns within each scale that actually impart the wings coloration. Thus, they were able to simultaneously replicate at the microscale, the nanoscale, the millimeter scale, and the centimeter scale.

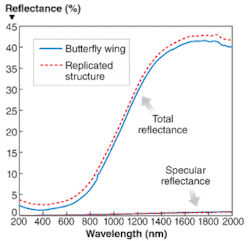

The faithfulness of the replica was also evidenced in precisely replicated optical performance. Transmission and reflection curves showed less than 5% difference between a butterfly’s wing and its glass replica. The difference is primarily due to differences in material composition (see figure). The ability to narrow the difference further by adjusting the proportions of germanium, antimony, and other dopants in the chalcogenide glass turns out to be just one of several advantages in using that particular material system.

The primary advantage is that the chalcogenide glasses are stable and sturdy materials that can withstand variations in temperature, pressure, and moisture along with other potential environmental stresses. They are also highly transparent to infrared light and have somewhat nonlinear propagation properties that can be controlled dynamically by the intensity of light passing through them. The new technique is not limited, of course, either to chalcogenide glass materials or even to optical applications, but might also be used to manufacture replicas of three-dimensional embedded structures in general, such as the surfaces of microelectronics circuits, Lakhtakia added.

REFERENCES

- R.J. Martín-Palma et al., Nanotechnology 19, 355704, 2008; doi:10.1088/0957-4484/19/35/355704.

- R.J. Martín-Palma et al., APL 93, 083901 (2008); DOI: 10.1063/1.2973167.

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.